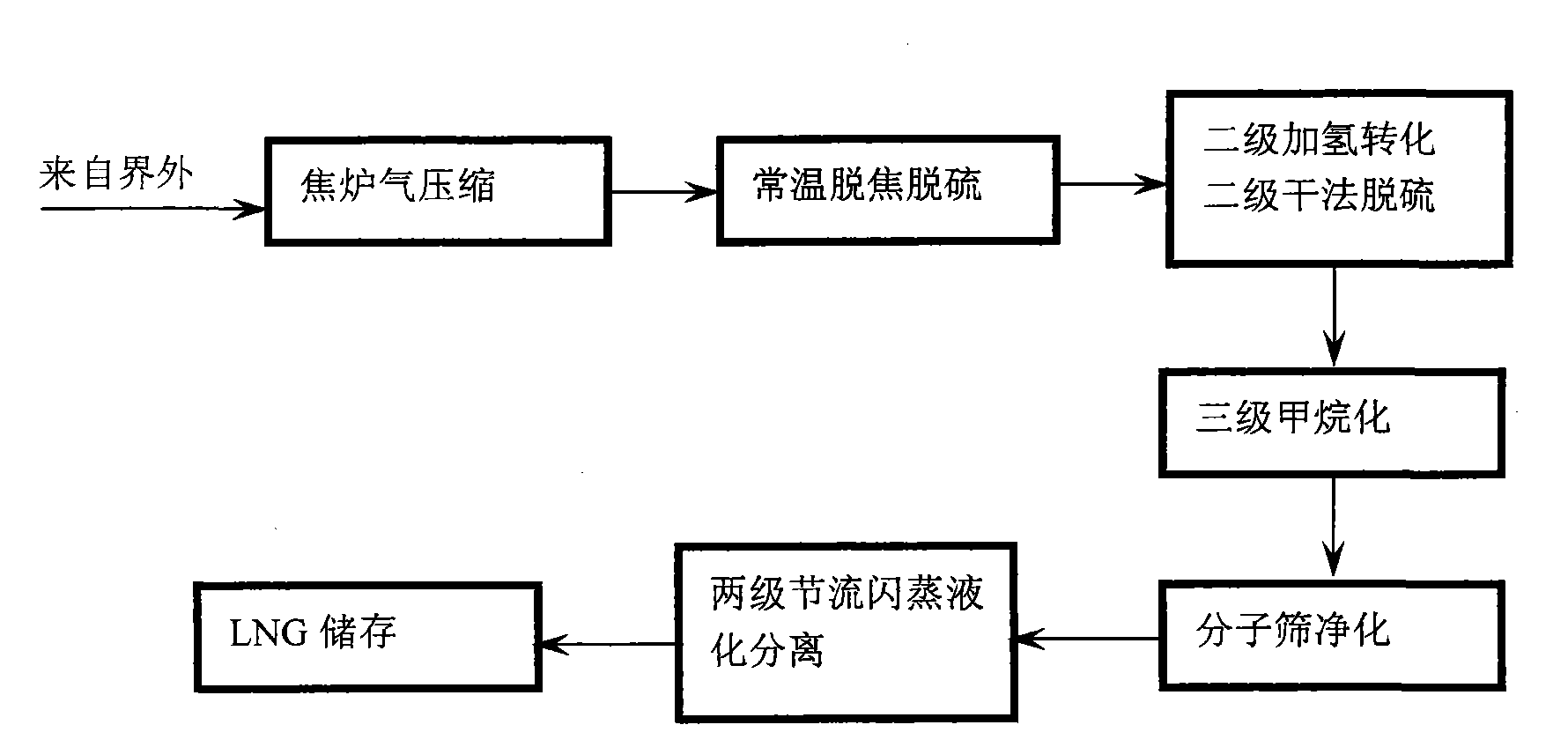

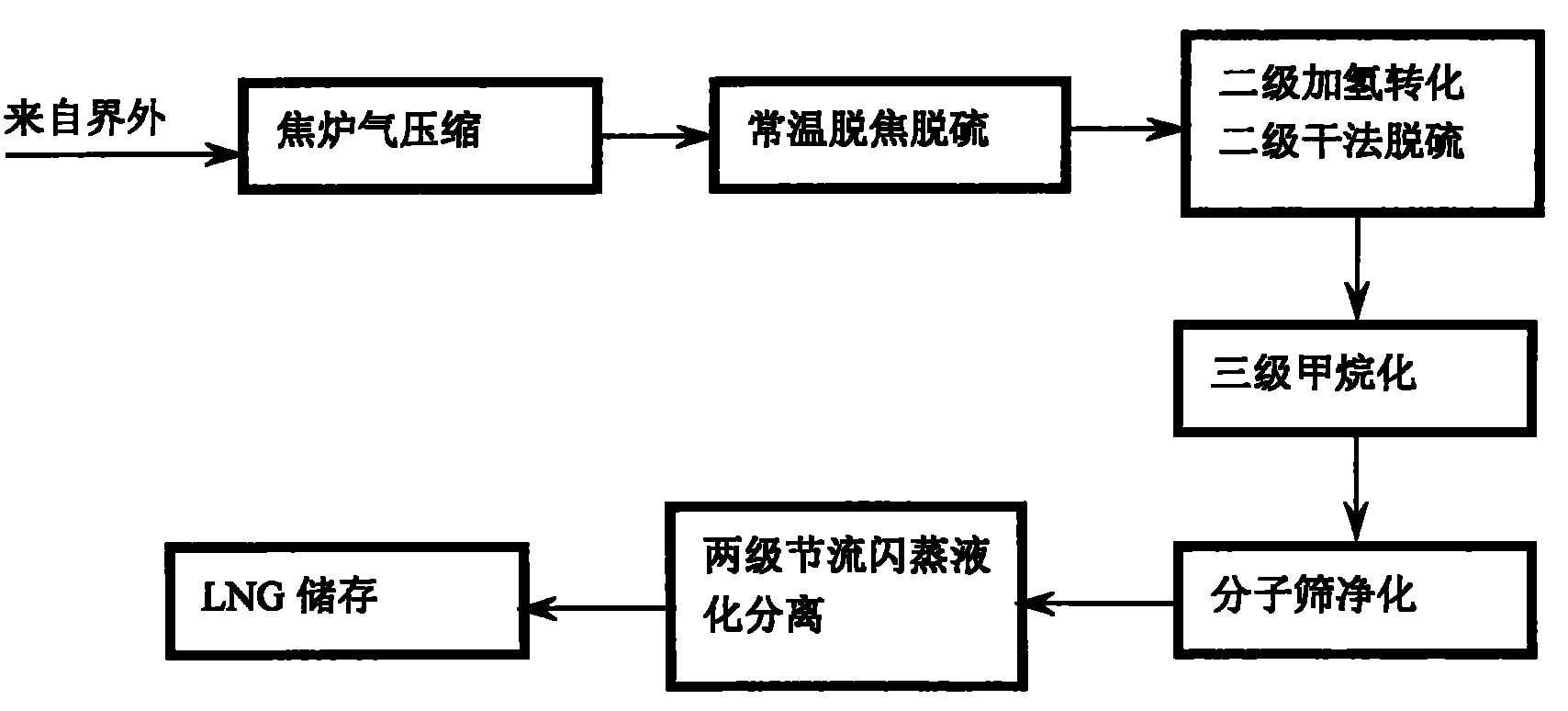

Process method for preparing LNG from coke oven tail gas

A process method and technology for coke oven tail gas, which are applied in the petroleum industry, gas fuel, and combustible gas purification, etc., can solve the problems of lack of total sulfur removal measures, affecting the quality of finished LNG, and lack of utilization, etc., so as to facilitate application and emergency replenishment. and storage, ease of procurement and supply, the effect of ease of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Production scale

[0049] Processing coke oven coal: 30000m 3 / h

[0050] 720,000m 3 / d

[0051] Product: LNG: 11000Nm 3 / h

[0052] By-product: H 2 :5000Nm 3 / h (Preliminary estimate based on current composition)

[0053] Annual operating hours: 8000h

[0054] Product solutions:

[0055] LNG: 11000Nm 3 / h 7.8712t / h(-135℃,0.6MPa·G)

[0056] 62769.6t / a

[0057] H 2 :5000m 3 / h

[0058] 165,600m 3 / d

[0059] Product technical quality index

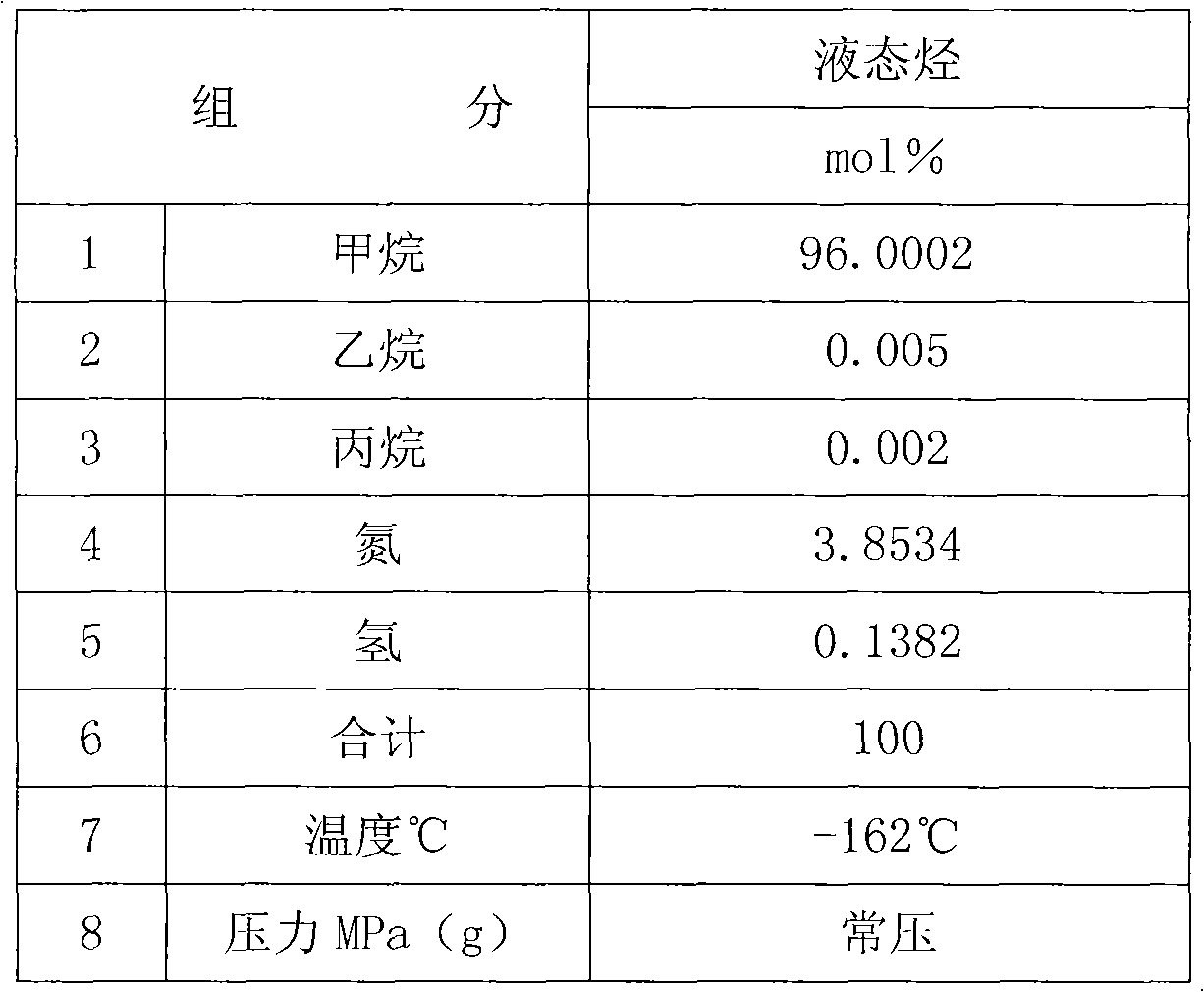

[0060] LNG product specifications

[0061]

[0062] Calorific value: index>31.4MJ / Nm 3 , This product exceeds 34MJ / N m 3 H 2 Technical index (after refining)

[0063] composition

H2

CO+CO 2

N2

CH 4

V%

≥99.9%

≤20ppm

≤0.04%

≤5ppm

O2

H 2 O

NH 3

C 2 H 2

≤5ppm

≤2mg / m 3

≤5ppm

≤10ppm

Total S

≤1ppm

pressure

≥1.4

MPa(G)

[0064] composition

H2

CO+CO 2

N2

CH 4

temperature

≤40℃

[0065] Note: This technological scheme does not include hydrogen refining for the time being. If refining is required, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com