Heat treatment process for mining cone bit friction pair

A technology of roller cone bits and friction pairs, which is applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve problems such as the difference in service life of friction pairs, and achieve the effects of increasing service life, reducing mining costs and improving working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Since it is determined that the quenching temperature of the gears and claws is the main heat treatment parameter that affects the life of the friction pair, it is determined that the parameters related to carburization of the gears and claws are the most difficult heat treatment parameters to control, and through a large number of series of experiments. The setting target of the carbon concentration of the respective carburized layer of the wheel and claw is the most critical parameter. therefore:

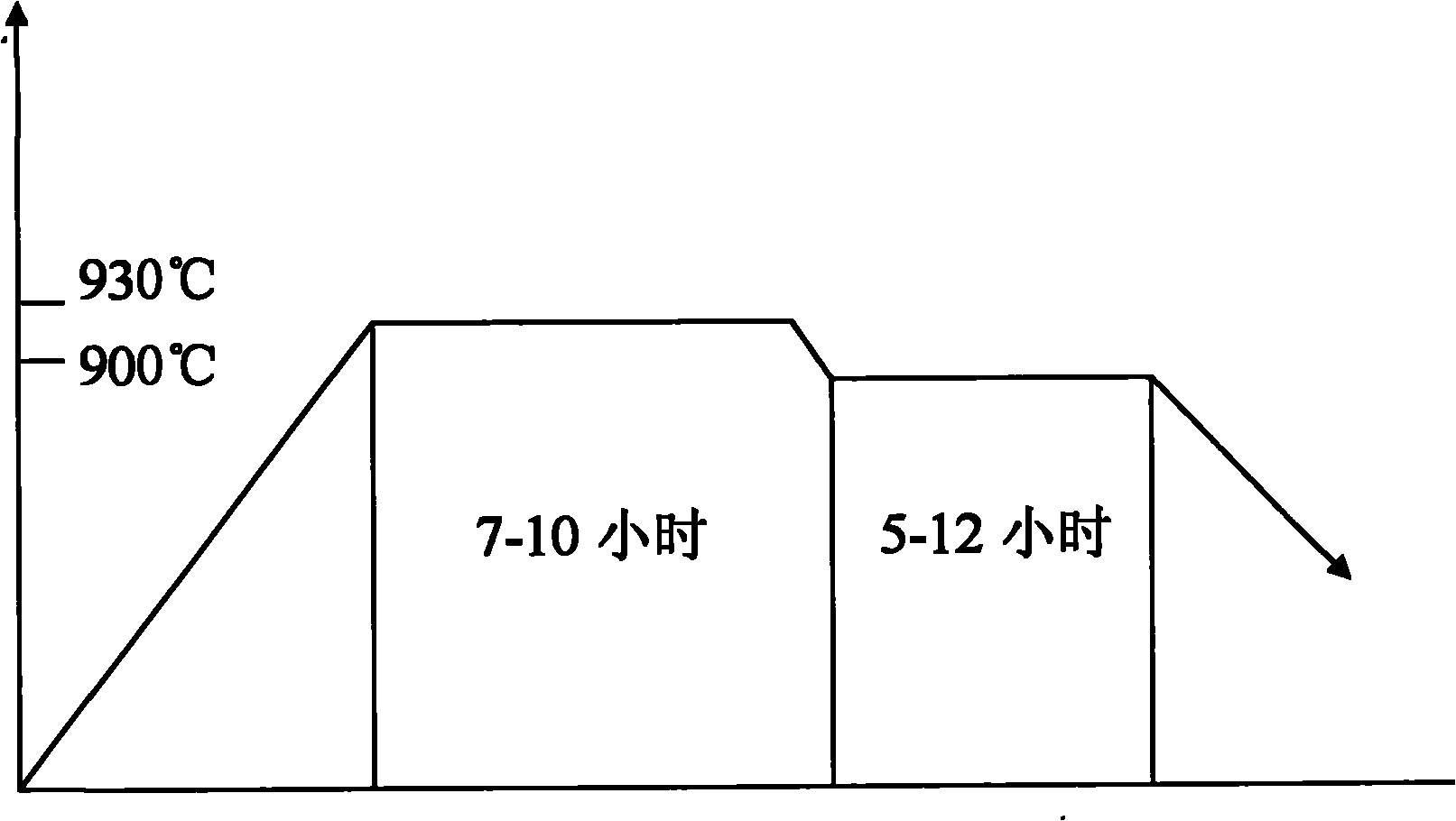

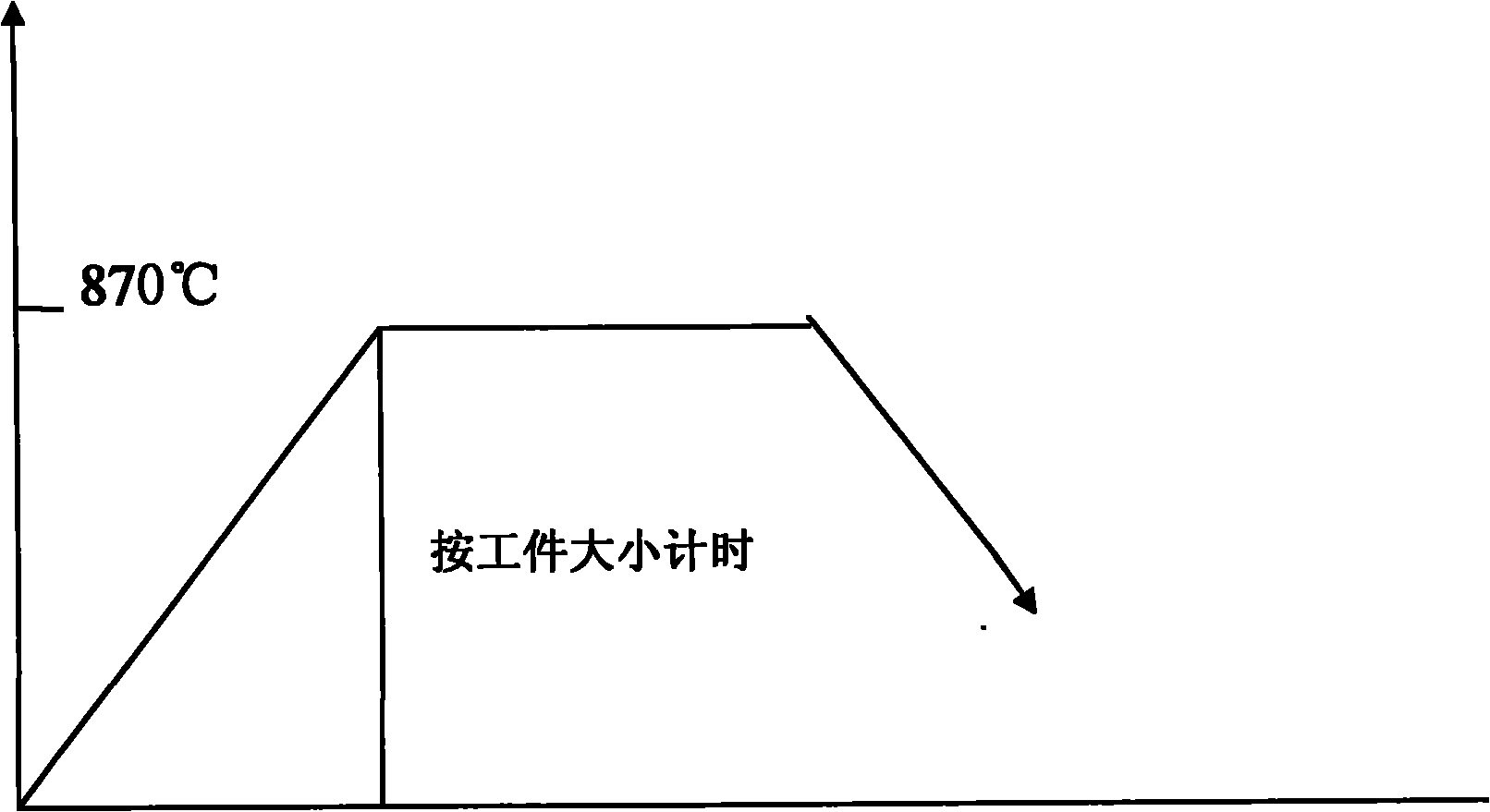

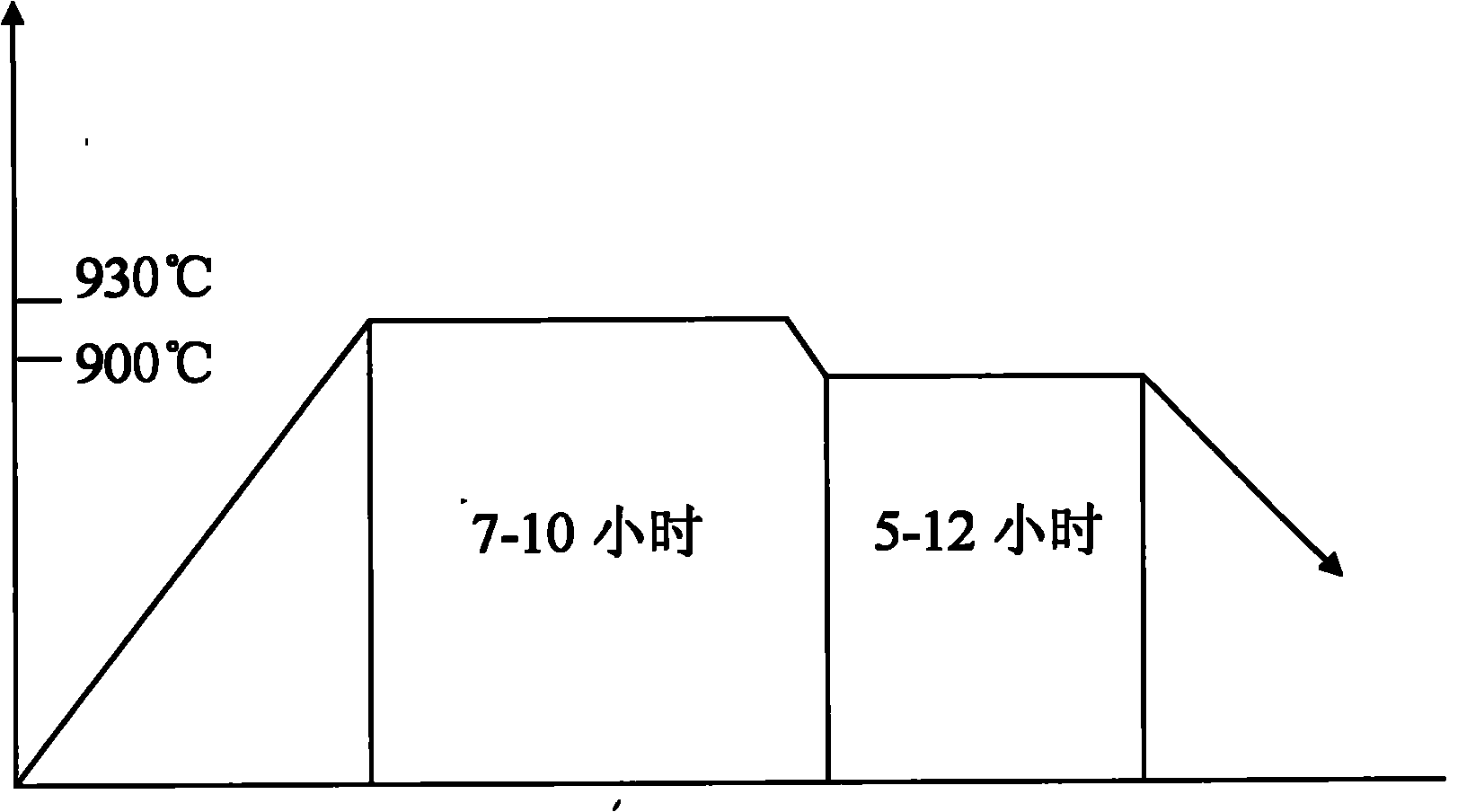

[0010] Taking the claws made of 20CrNiMo material as an example, the carburizing process is as follows: strong infiltration temperature 930 ° C, diffusion temperature 900 ° C; strong infiltration and diffusion time depend on the depth requirements of the infiltration layer, and the final surface carbon concentration is controlled at 0.85% ~ 1.05 %, the penetration layer depth is 2.5mm ~ 3.0mm. The quenching temperature is 815°C, the heating time depends on the size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com