Method for molding vertical wall of deep foundation pit

A forming method and deep foundation pit technology, which can be applied in excavation, foundation structure engineering, blasting, etc., can solve problems such as the inability to construct the foundation of the factory building, affect the promotion of construction technology, and the instability of the foundation pit structure, so as to achieve good comprehensive benefits and good promotion The effect of low value and construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and specific embodiments.

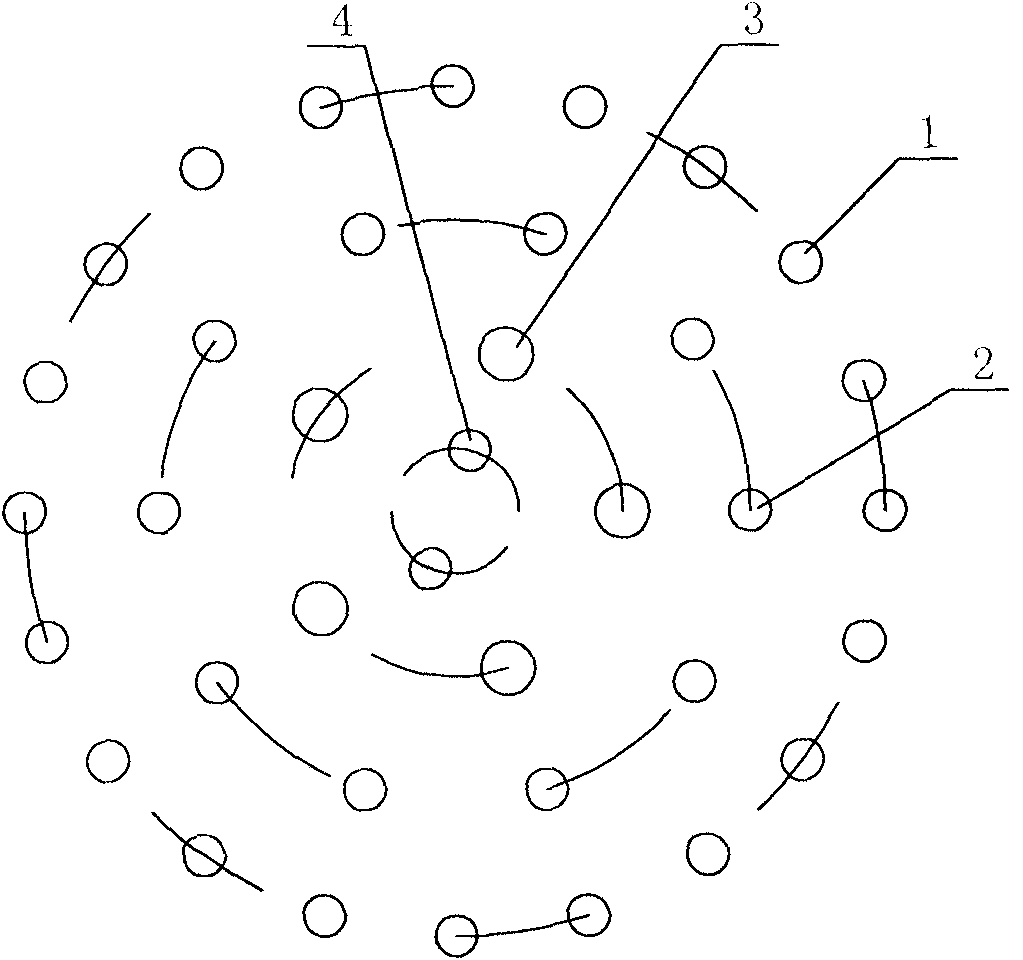

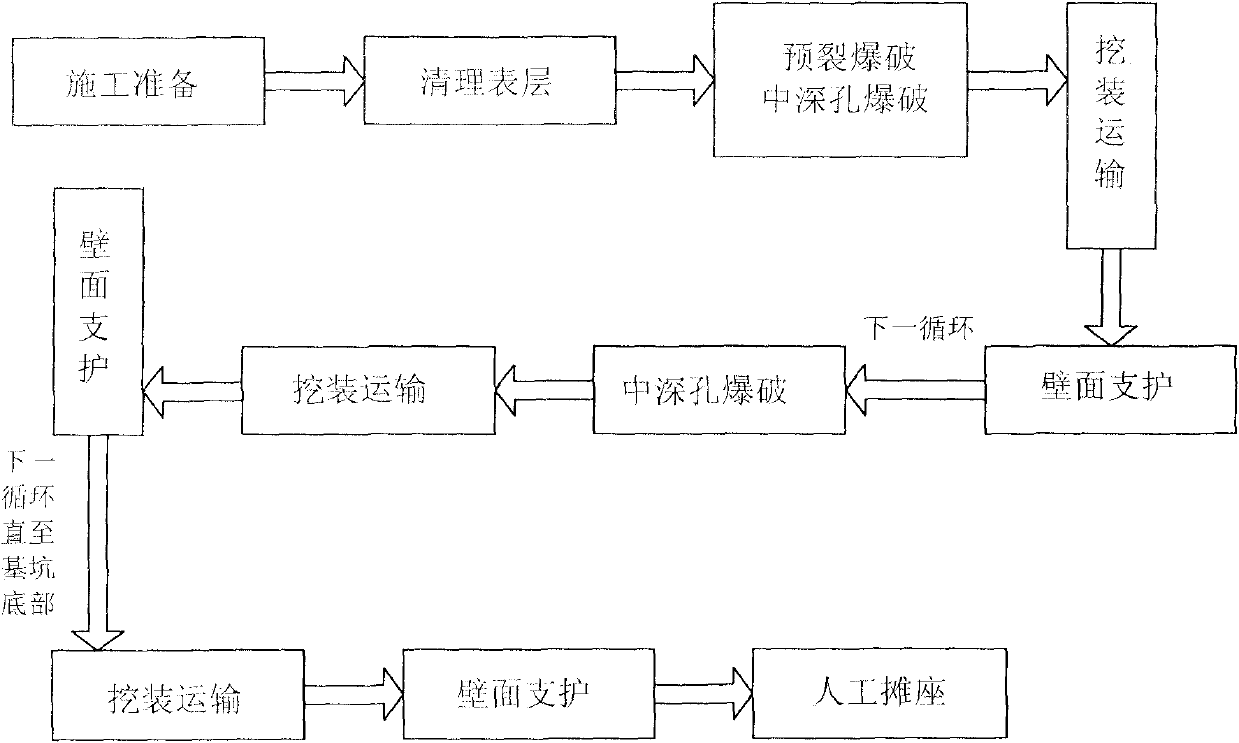

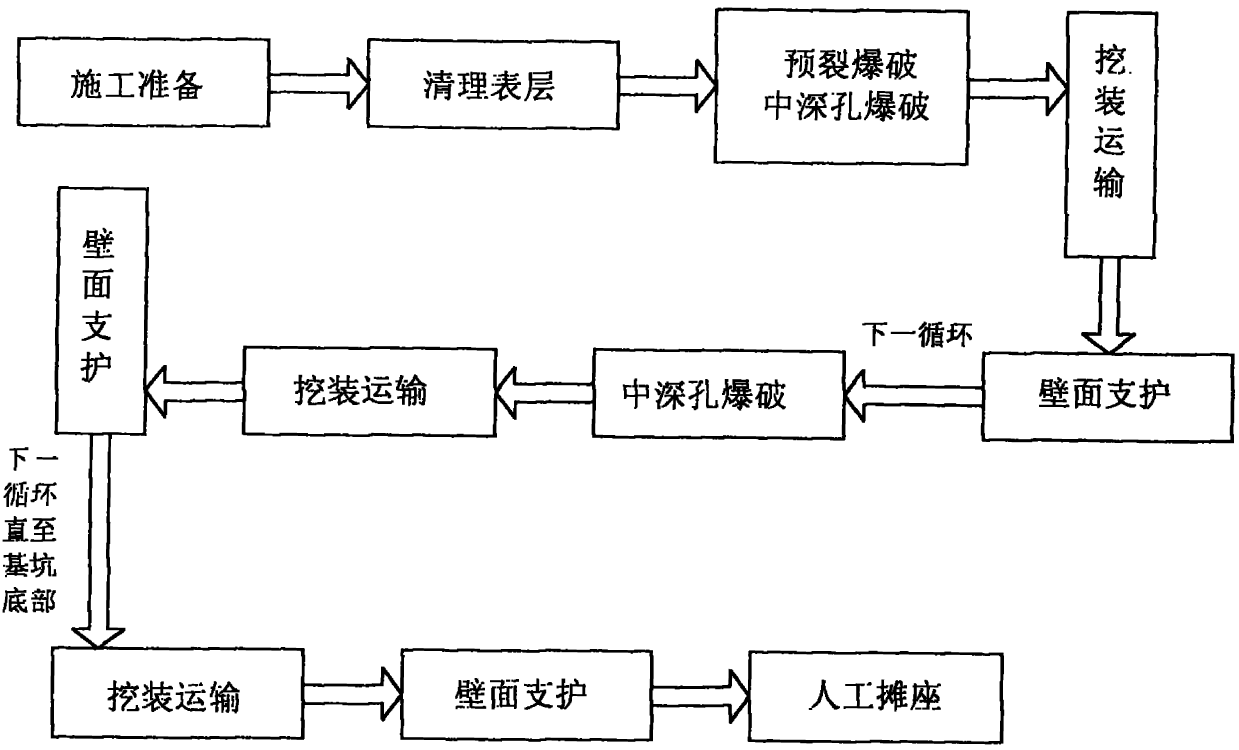

[0019] Such as figure 1 with figure 2 As shown, a method for forming a straight wall of a deep foundation pit is based on the shape characteristics and requirements of the foundation pit, as well as the environmental restrictions on blasting engineering, and adopts controlled blasting with peripheral pre-splitting and central layered loosening, including the following steps: ( 1) Set pre-split holes 1: According to the design requirements, drill a number of pre-split holes 1 on the edge of the preset range of the foundation pit. The pre-split holes 1 are formed by one-time drilling at the full depth of the pit, and each pre-split hole is filled with explosives Coil and the detonating cord connected to the explosive coil, the detonating cord is connected to the instantaneous detonator outside the hole, the pre-split hole adopts uncoupled charge, the non-coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com