Masonry type building surface particle spraying retreading construction method

A construction method and building technology, applied in the direction of building structure and construction, can solve the problems of shortening the service life of the building, affecting the cleanliness and beauty of the building, etc. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

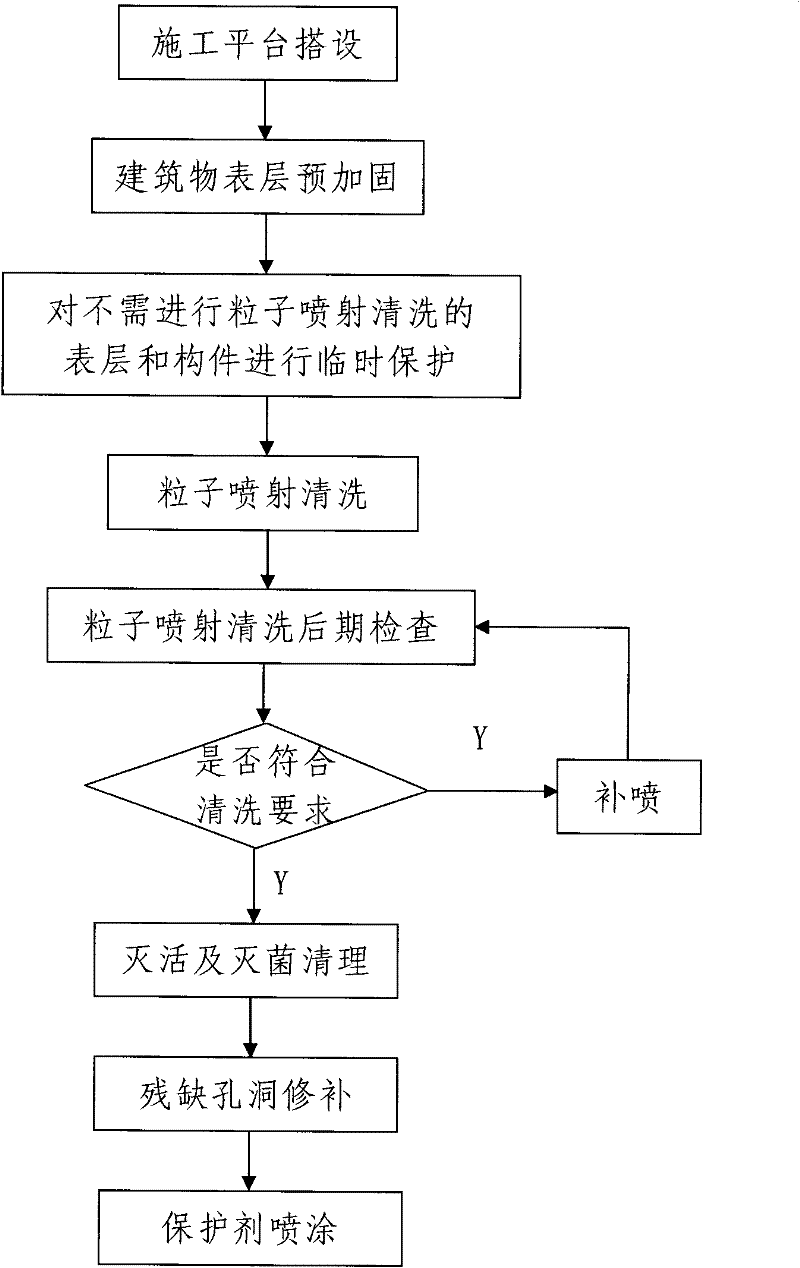

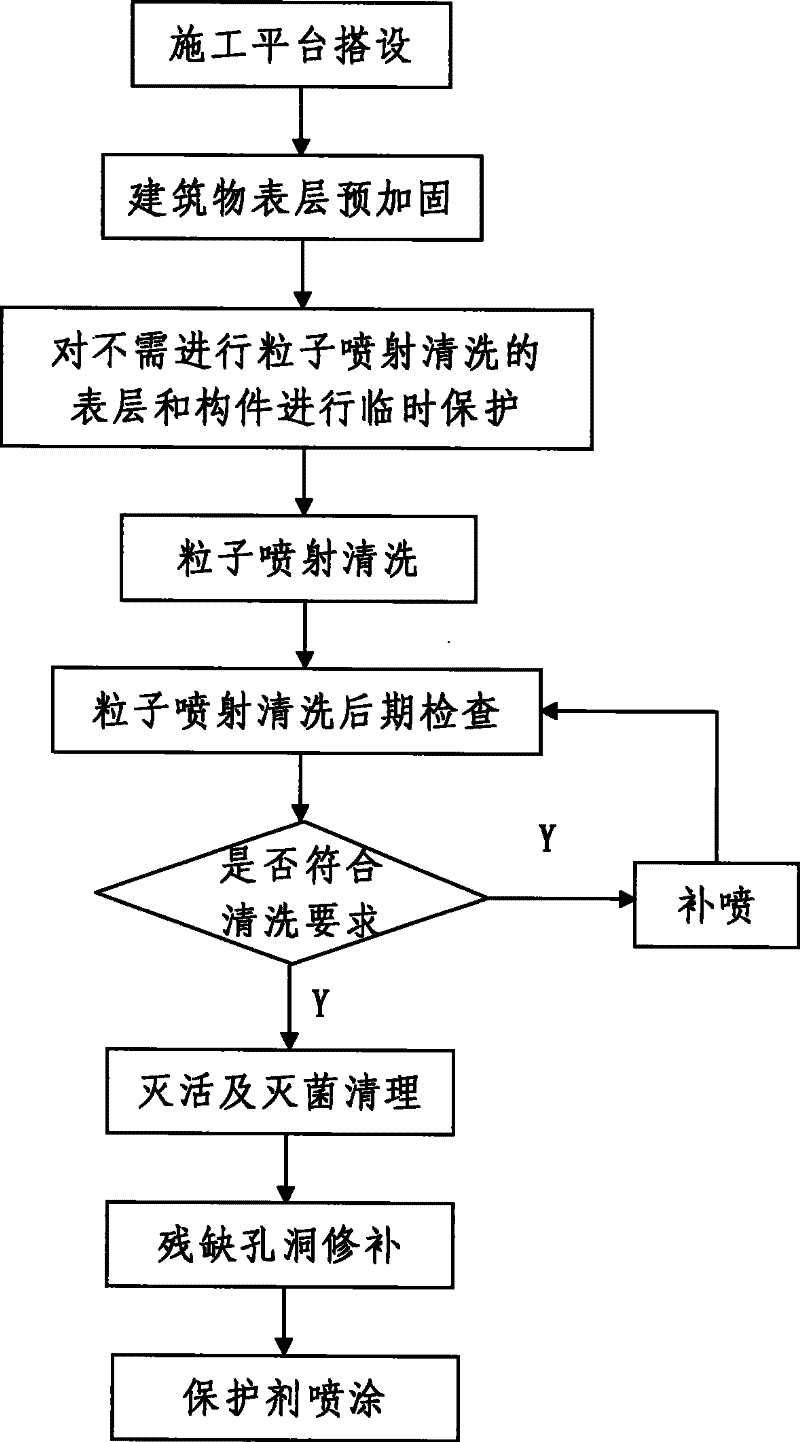

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the construction platform is scaffolding, and the sealing layer is surrounded by tarpaulin or plastic cloth. In this embodiment, the caliber of the air pressure spray gun nozzle is 3mm, the pressure of the ejected airflow is 8Pa and the air output is 1m 3 / min, the moving speed of described pneumatic spray gun is 400mm / s; Particle (being quartz sand particle) jet cleaning construction process, the vertical spraying distance of described pneumatic spray gun is 40cm, and the injection direction of described pneumatic spray gun and The inclination angle between the surfaces to be treated in masonry buildings is 45°. In this embodiment, the building protection agent is an emulsion-type silicone water-repellent agent. After evenly spraying the protective agent, it can effectively reduce the water absorption performance of bricks, stones and other materials, and does not change the color and air permeability of the surface layer of the treated building, e...

Embodiment 2

[0043] In this embodiment, the difference from Embodiment 1 is that the caliber of the pneumatic spray gun nozzle described in step 2 is 4mm, the pressure of the ejected air flow is 10Pa and the air output is 2m 3 / min, the moving speed of the air-pressure spray gun is 800mm / s; Particles (i.e. corundum powder particles) jet cleaning construction process, the vertical spray distance of the air-pressure spray gun is 60cm, the spray direction of the air-pressure spray gun and The inclination angle between the surfaces of masonry buildings to be treated is 15°, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0045] In this embodiment, the difference from Embodiment 1 is that the caliber of the pneumatic spray gun nozzle described in step 2 is 5mm, the pressure of the ejected air flow is 12Pa and the air output is 3m 3 / min, the moving speed of described pneumatic spray gun is 1200mm / s; Particle (being calcite powder particle) jet cleaning construction process, the vertical spray distance of described pneumatic spray gun is 80cm, and the injection direction of described pneumatic spray gun and The inclination angle between the surfaces to be treated of masonry buildings is 90°, and the rest of the steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com