Non-aqueous electrolyte secondary battery and method of manufacturing the same

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte storage batteries, electrolyte storage battery manufacturing, battery electrodes, etc., can solve the problems of energy density reduction, achieve the reduction of discharge load characteristics, excellent storage stability, and improve The effect of saving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

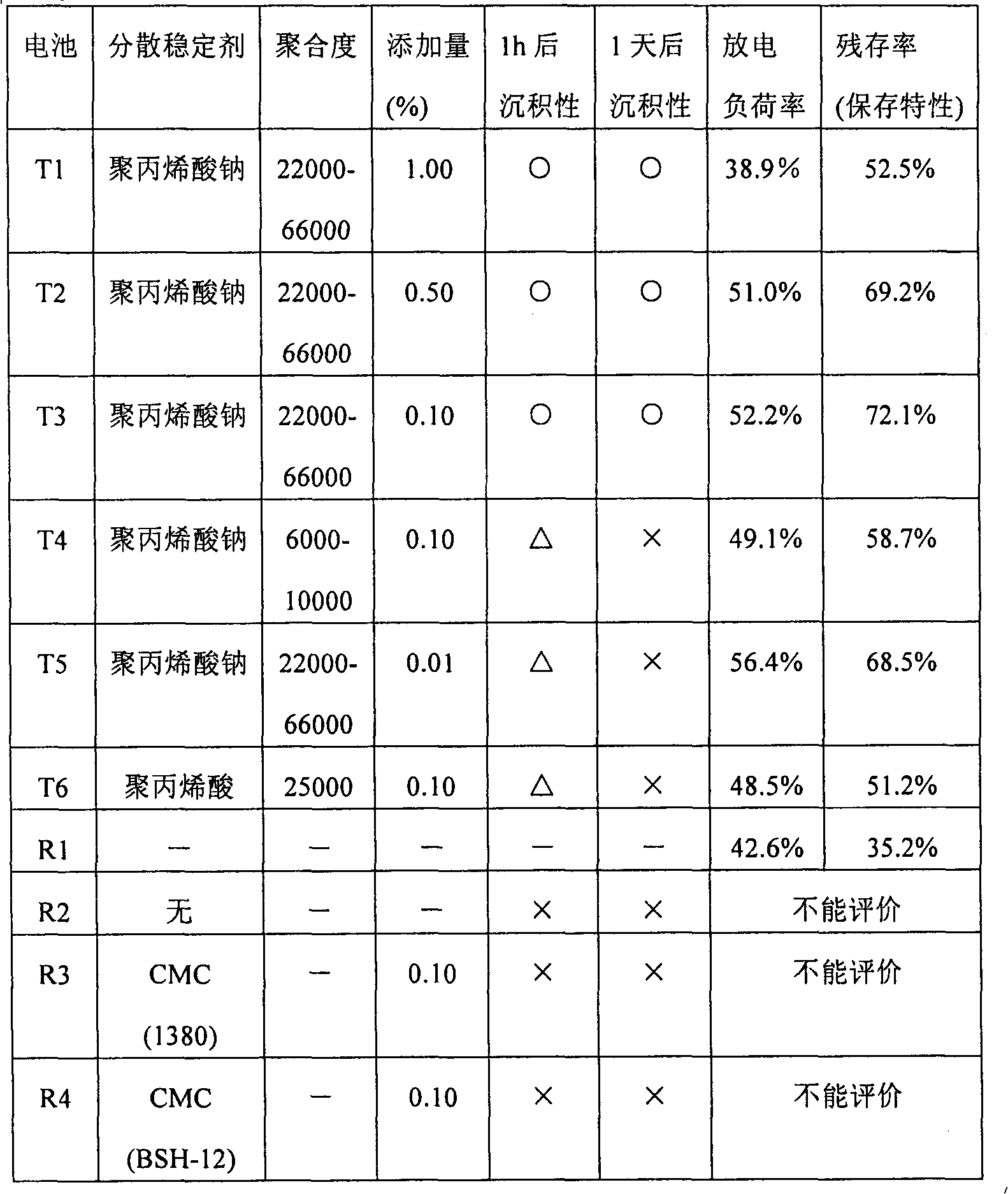

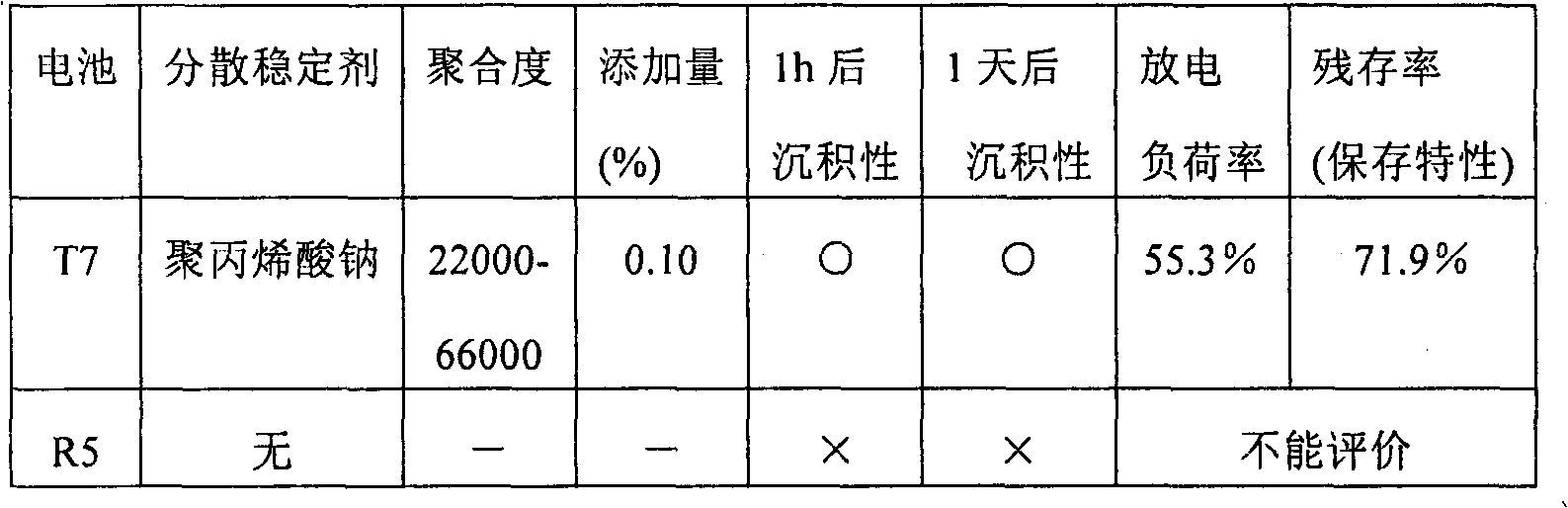

Examples

Embodiment 1

[0051] [Formation of positive electrode]

[0052] As the positive electrode active material, lithium cobaltate in which 1.0 mol % of Al and Mg were solid-dissolved and 0.05 mol % of Zr was produced was produced. The positive electrode active material, acetylene black as a carbon conductive agent, and PVDF (polyvinylidene fluoride) were mixed in a mass ratio of 95:2.5:2.5, and NMP was used as a solvent by using a mixer to prepare a positive electrode slurry. This was applied to both sides of an aluminum foil, dried, and then rolled to produce a positive electrode. It should be noted that the packing density of the positive electrode is set at 3.60g / cm 3 .

[0053] It should be noted that, as the positive electrode active material, a positive electrode active material having a layered structure can be used. Among them, lithium-containing transition metal oxides having a layered structure are preferably used. In addition, when the charge termination potential of the positive ...

Embodiment 2

[0077] A battery was fabricated in the same manner as in Example 1 except that sodium polyacrylate was added at 0.50 parts by mass with respect to 100 parts by mass of the inorganic particles. Let this battery be battery T2.

Embodiment 3

[0079] A battery was fabricated in the same manner as in Example 1, except that sodium polyacrylate was added as a dispersion stabilizer in an amount of 0.10 parts by mass relative to 100 parts by mass of the inorganic particles. Let this battery be battery T3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com