Stirring and grinding reactor and method for preparing isocyanate with same

A technology of a reactor and a reactor shell is applied in the field of stirring and grinding reactors, which can solve the problems of large energy consumption, inability to achieve rapid and instant mixing of large-flow materials, and prolonging the mixing time, so as to reduce side reactions and shorten the mixing time. , to avoid the effect of wrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] In the process of producing toluene diisocyanate (TDI), the initial mixing of the reaction raw materials toluene diamine and phosgene has an important influence on the yield of the final product. It is generally required that the time scale of the two materials in the initial mixing stage is at the millisecond level. To suppress the occurrence of side reactions and increase the yield of the target product.

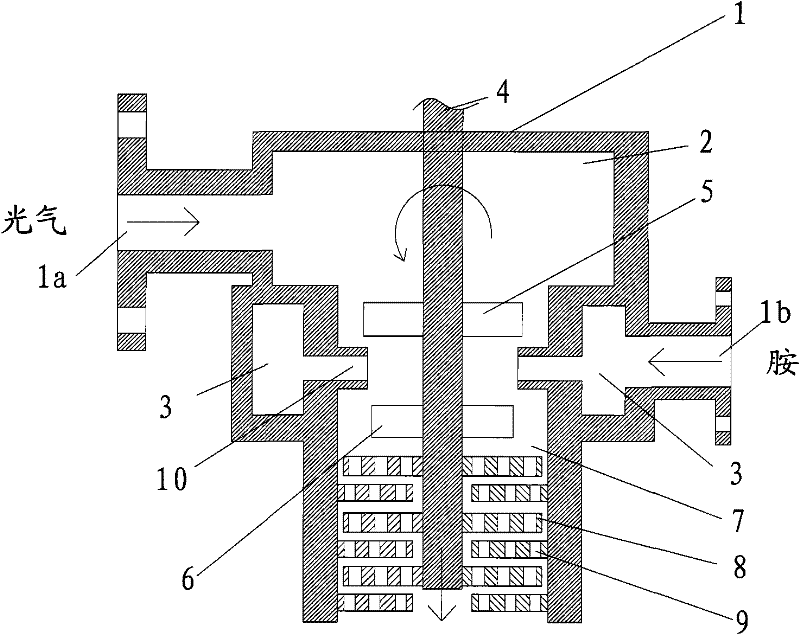

[0056] use as figure 1 The shown reactor produces toluene diisocyanate (TDI), wherein: the reaction channel adopts a circular shape with a diameter of 100mm, and the stirring shaft rotating speed is 400r / min. Figure 4 The axial stirring impeller shown is a first-stage axial stirring impeller with 3 blades, and the diameter of the outer edge of the blade is 90mm; there are 4 feeding ports for the amine solution, with a round hole design, and the hole diameter is 2mm, which is compatible with the stirring The axis is vertical, and the distance between the feed inlet...

Embodiment 2

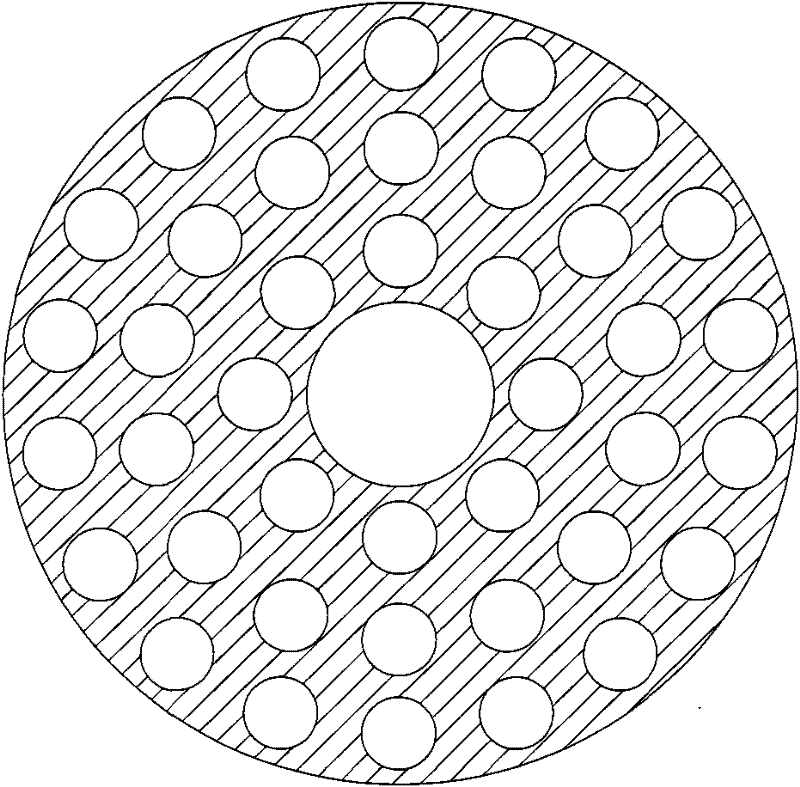

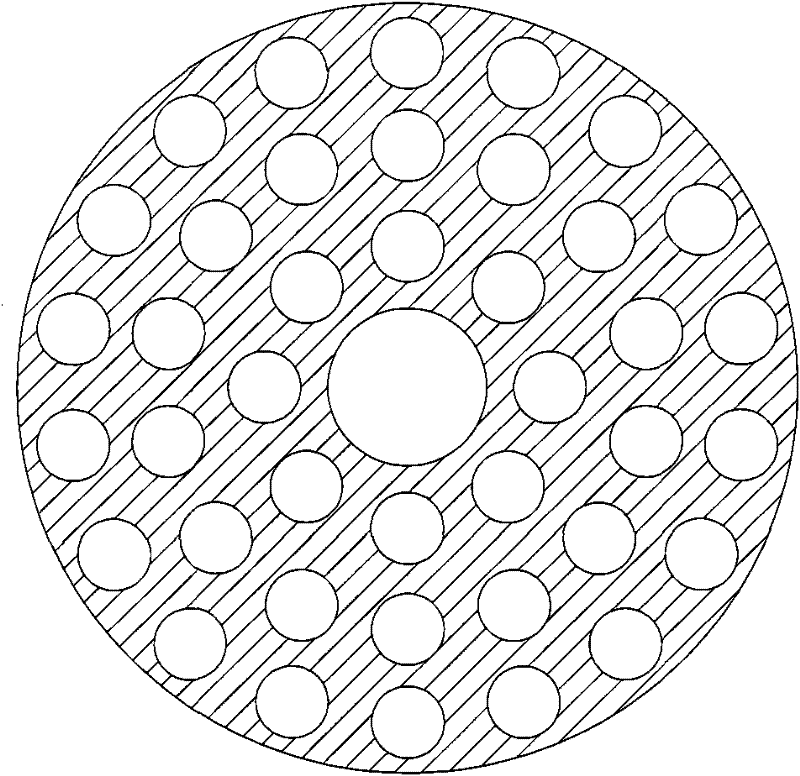

[0058] use figure 1 The shown reactor of the present invention produces toluene diisocyanate (TDI), wherein: the reaction passage adopts circular, diameter 100mm, and the stirring shaft rotating speed is 300r / min, adopts such as Figure 4 The axial stirring paddle shown is a first-stage axial stirring paddle with 3 paddles, and the diameter of the outer edge of the paddle is 90mm; there are 4 feeding ports for the amine solution, and the square hole is designed with a side length of 2mm. The axis is vertical, and the distance between each sub-feed inlet and the inner wall of the reaction channel is l=15mm; the radial stirring paddle is 2 stages, each stage has 3 blades, and the diameter of the outer edge of the blade is 60mm; figure 2 and image 3 For the dynamic and static grinding plates shown, the radial distance from the outermost edge of the dynamic grinding plate to the inner wall of the reaction channel is 2mm, the radial distance from the innermost edge of the static...

Embodiment 3

[0060] use figure 1 The shown reactor of the present invention produces toluene diisocyanate (TDI), wherein: the reaction passage adopts circular, diameter 120mm, and the stirring shaft rotating speed is 400r / min, adopts such as Figure 4 The axial stirring paddle shown in the figure is a first-stage axial stirring paddle with 3 paddles, and the diameter of the outer edge of the paddles is 90mm; there are 4 feeding ports for the amine solution, and the circular hole is designed with a diameter of 2mm. The feeding inlet is inclined downward so that its central axis and the stirring shaft form an angle of 70°, and the distance between each sub-feeding inlet and the inner wall of the reactor shell is l=10mm; the radial stirring paddle is 1 stage, with 3 paddles Blade, the diameter of the outer edge of the blade is 65mm; figure 2 and image 3 For the dynamic and static grinding plates shown, the radial distance from the outermost edge of the dynamic grinding plate to the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com