Pipeline and dwell tank desiliconization method of fly ash

A technology for fly ash and desiliconization, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems of low aluminum-silicon ratio of fly ash slurry, simplify the production process, and prevent belt material, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

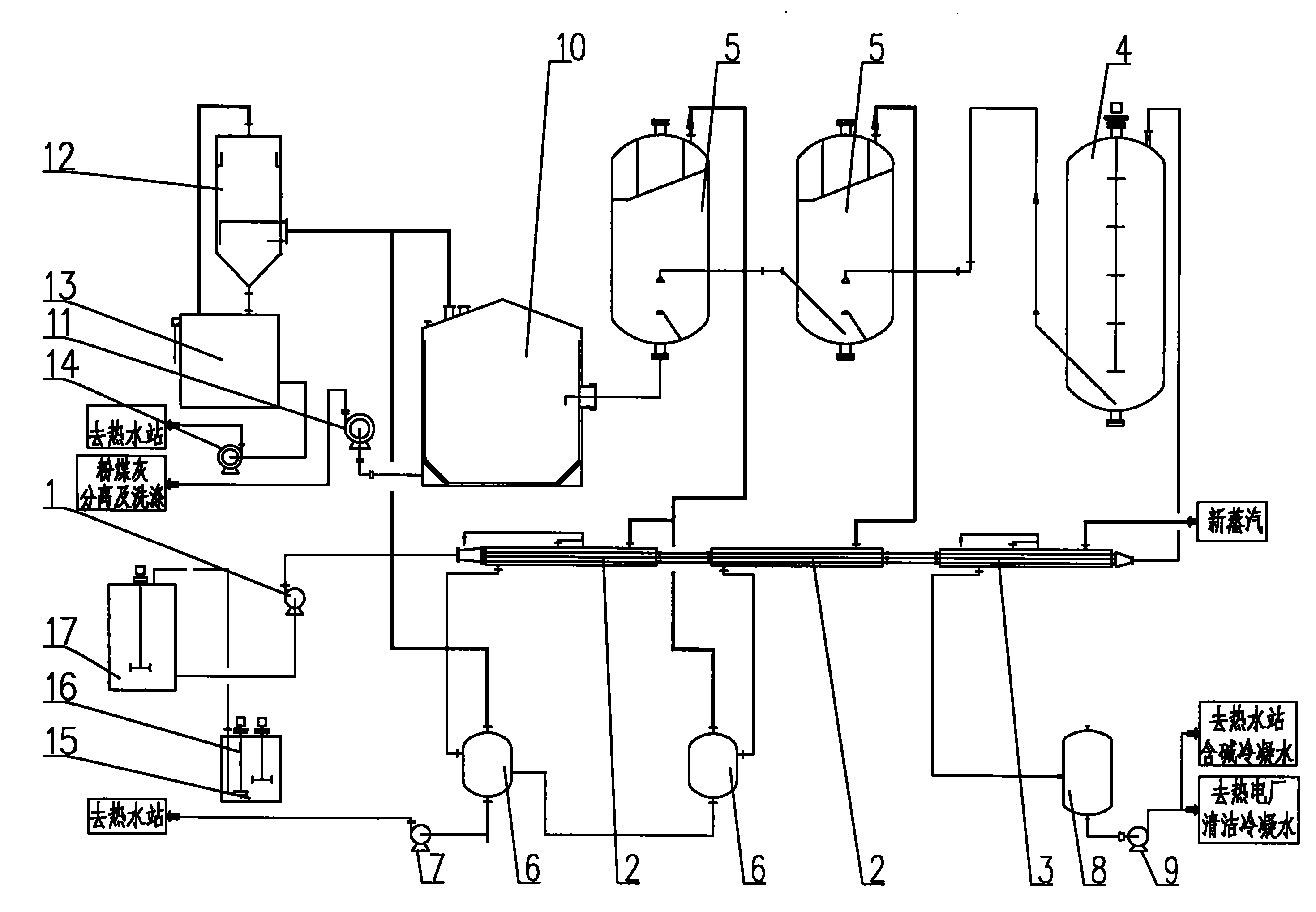

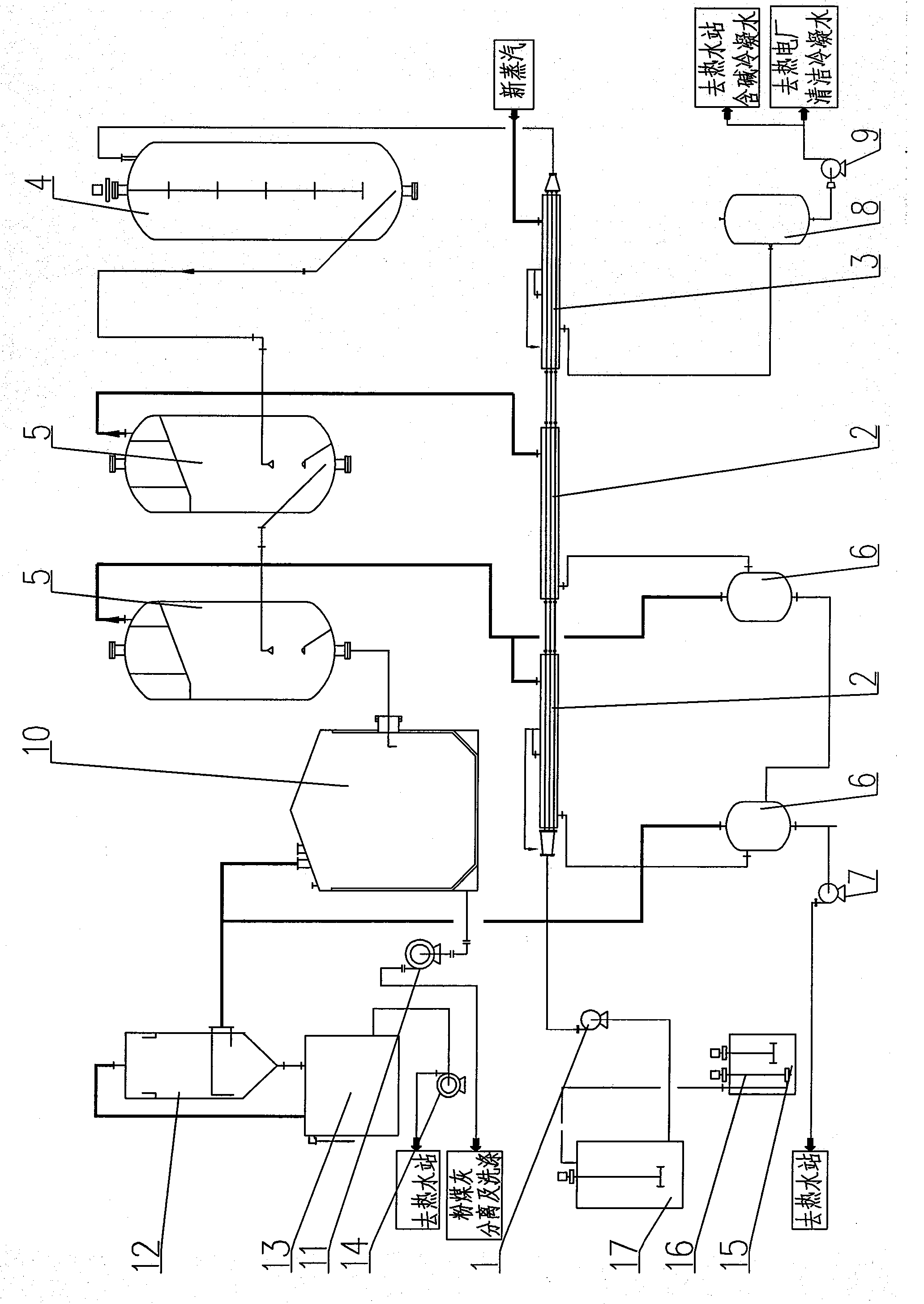

[0033] The process is as follows.

[0034] (1) adding the fly ash with an alumina content of 45.6% to the NaOH solution with a mass percentage concentration of 40% is prepared into a fly ash slurry, and the prepared fly ash slurry has a liquid-to-solid mass ratio of: liquid: Solid = 3.5:1. The fly ash slurry is sent to the second-stage multi-inner-pipe casing preheater through the feed pump, and the temperature of the slurry is preheated to 73°C.

[0035] The blending is carried out in the fly ash pre-deployment discharge tank, which is connected with the sewage tank equipped with a submerged pump.

[0036] The second-stage multi-inner tube casing preheater is composed of two identical multi-inner tube casing preheaters, and the heat source of the second-stage multi-inner tube casing preheater is the steam of the secondary flash evaporator. The secondary flash evaporator consists of two identical flash evaporators. The condensed water from the secondary flash evaporator ent...

Embodiment 2

[0047] The process is as follows.

[0048] (1) join the fly ash that aluminum oxide content is 51% in the NaOH solution that mass percent concentration is 50%, deploy into fly ash slurry, the fly ash slurry liquid-solid mass ratio of allotment is: liquid: Solid = 4:1. The fly ash slurry is sent to the second-stage multi-inner-tube casing preheater through the feed pump, and the temperature of the slurry is preheated to 75°C.

[0049] The blending is carried out in the fly ash pre-deployment discharge tank, which is connected with the sewage tank equipped with a submerged pump.

[0050] The second-stage multi-inner tube casing preheater is composed of two identical multi-inner tube casing preheaters, and the heat source of the second-stage multi-inner tube casing preheater is the steam of the secondary flash evaporator. The secondary flash evaporator consists of two identical flash evaporators. The condensed water from the secondary flash evaporator enters the secondary stea...

Embodiment 3

[0061] The process is as follows.

[0062] (1) join the fly ash that aluminum oxide content is 40% in the NaOH solution that mass percent concentration is 30%, deploy into fly ash slurry, the mass ratio of the fly ash slurry liquid of allotment is: liquid: Solid = 3:1. The fly ash slurry is sent to the second-stage multi-inner-pipe casing preheater through the feed pump, and the temperature of the slurry is preheated to 70°C.

[0063] The blending is carried out in the fly ash pre-deployment discharge tank, which is connected with the sewage tank equipped with a submerged pump.

[0064] The second-stage multi-inner tube casing preheater is composed of two identical multi-inner tube casing preheaters, and the heat source of the second-stage multi-inner tube casing preheater is the steam of the secondary flash evaporator. The secondary flash evaporator consists of two identical flash evaporators. The condensed water from the secondary flash evaporator enters the secondary ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com