Method and device for delaying coking unwatering cyclone decoking

A technology of delayed coking and hydrocyclone, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the unsolved problems of scientific purification of sewage in the venting system of delayed coking units, which cannot Meet the expectations of petrochemical clean production industrialization and other issues, and achieve the effects of small footprint, small pressure loss, and easy maintenance

Inactive Publication Date: 2010-08-25

SHANGHAI HUACHANG ENVIRONMENT PROTECTION

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In short, due to the above-mentioned problems in the prior art, the problem of scientific purification of sewage in the venting system of the delayed coking unit has not been solved so far, and it is far from meeting the expectations of the industrialization of clean production in the petrochemical industry.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Login to View More

Abstract

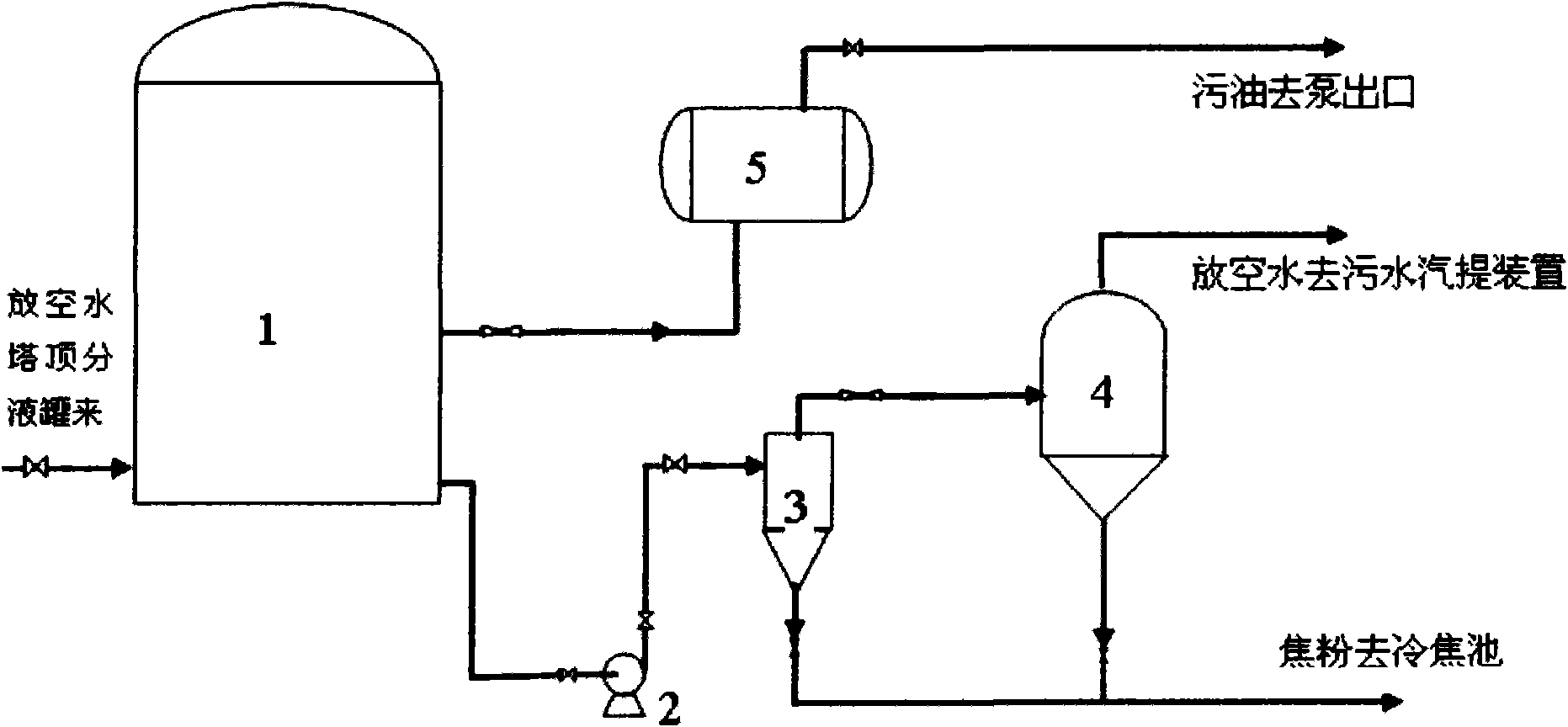

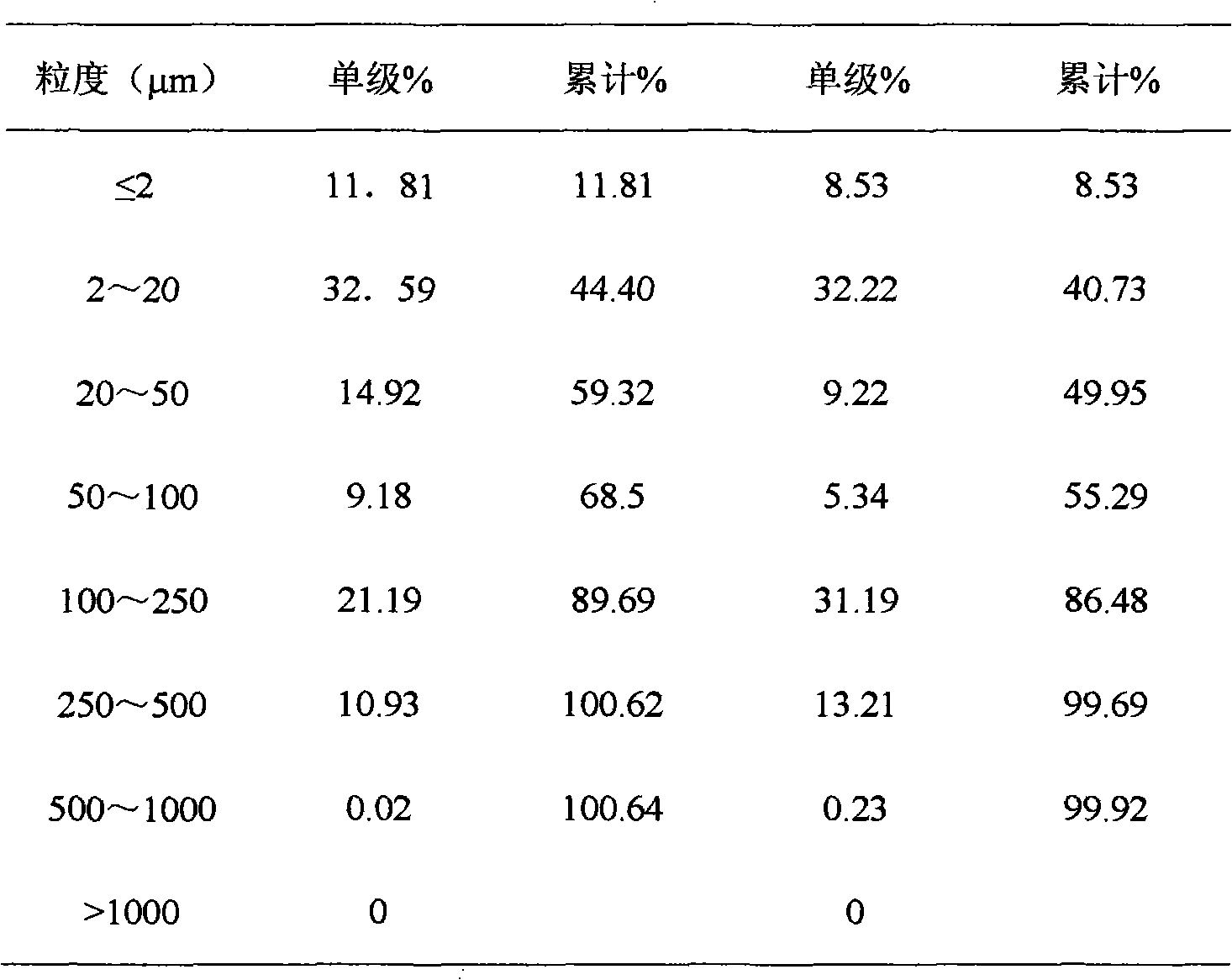

The invention provides a method and a device for delaying coking unwatering cyclone decoking with less investment, low energy consumption and high decoking efficiency. The method for delaying coking unwatering cyclone decoking comprises the following steps: settling separation, one-stage or two-stage or multistage cyclone decoking, and effluent oil separation. The method and the device for delaying coking unwatering cyclone decoking has the following advantages that: the separation efficiency is high; the separation precision of unwatering fine coke solid particles is 5 microns; the removal efficiency of particles with the separation precision of 5 microns or more is more than 95%; other solid particle impurities are removed while the fine coke solid particles are removed; the pressure loss is small; the operation is simple and convenient; the operation cost is low; the device has simple structure and occupies small area.

Description

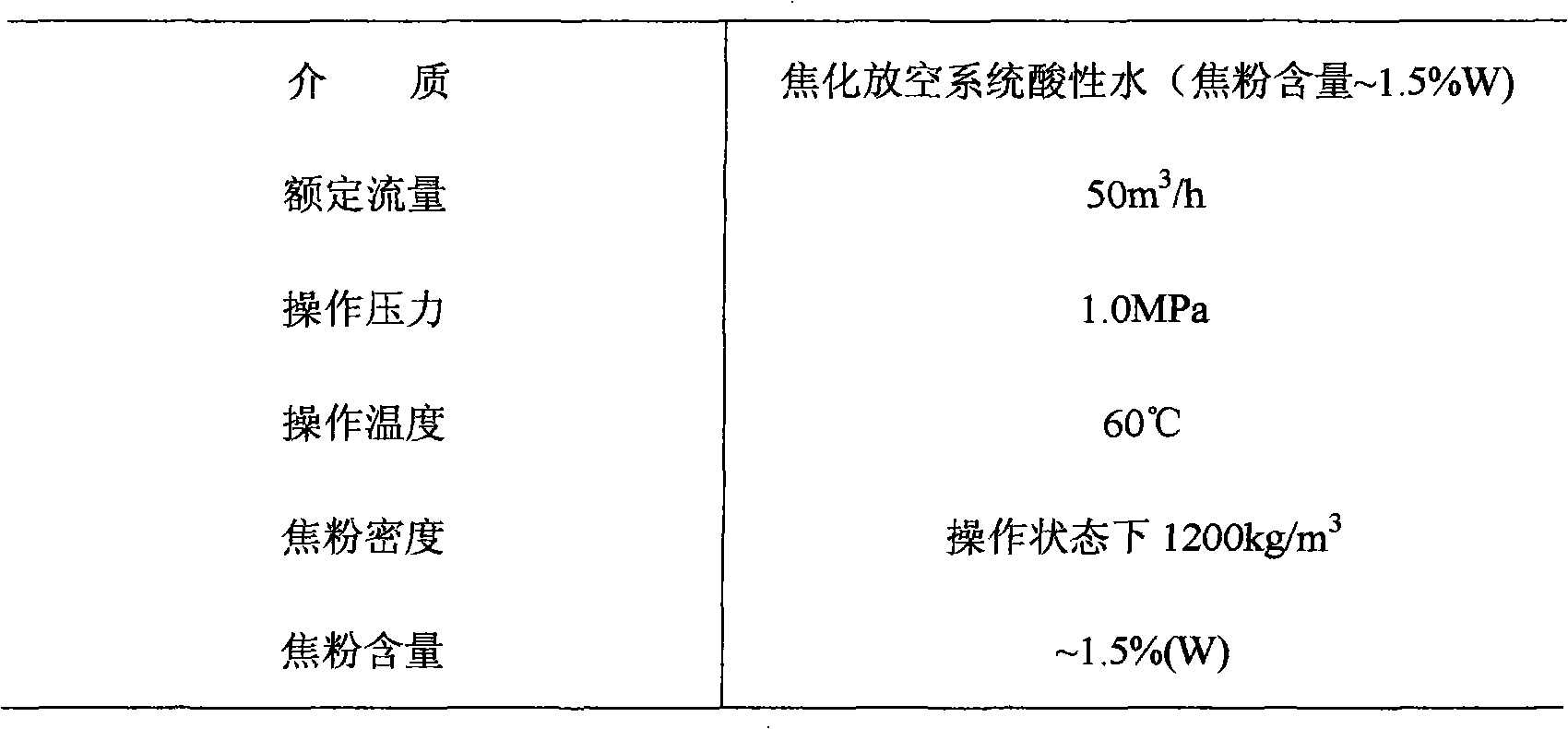

technical field The invention belongs to the technical field of chemical engineering and environmental protection, and relates to a method for removing coke powder solid particles in sewage, in particular to a treatment method for coke-containing sewage in a delayed coking venting water system, and a device for implementing the method. Background technique The delayed coking process is a major process in petroleum coking. This process is a process in which oil refineries use thermal cracking technology to upgrade and convert residual oil (such as atmospheric residual oil, vacuum residual oil, etc.) into gas, liquid products and solid petroleum coke of concentrated carbon substances. In order to control pollution and increase the stripping yield, the delayed coking unit is equipped with a gas venting system: after the coke tower is formed and before decoking, it is necessary to release the pressure and blow steam into the tower, and then inject water to cool it. In this proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F9/02C02F1/38

Inventor 钱卓群汪华林徐效梅杨强钱鹏吕文杰崔馨

Owner SHANGHAI HUACHANG ENVIRONMENT PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com