Method for preparing phenylacetate

A technology of phenyl acetate and acetic acid, applied in the field of preparation of phenyl acetate, can solve problems such as high cost, high equipment requirements, hydrogen chloride corrosion, etc., and achieve the effects of low production cost, simple operation and high atomic economy

Inactive Publication Date: 2010-08-25

SHANGHAI QIBAO HIGH SCHOOL

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

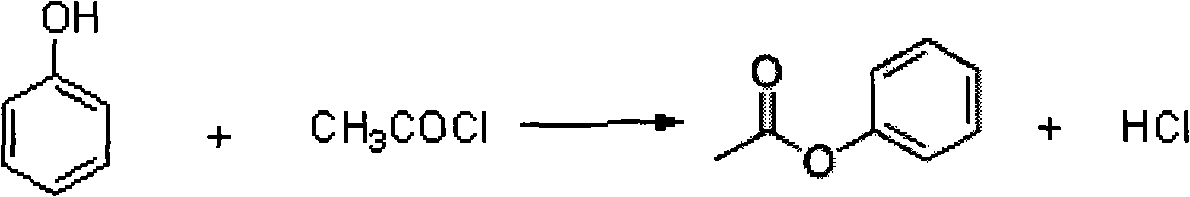

The synthesis of phenyl acetate with acetyl chloride has the disadvantages of high cost, high equipment requirements, and serious corrosion of by-product hydrogen chloride.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

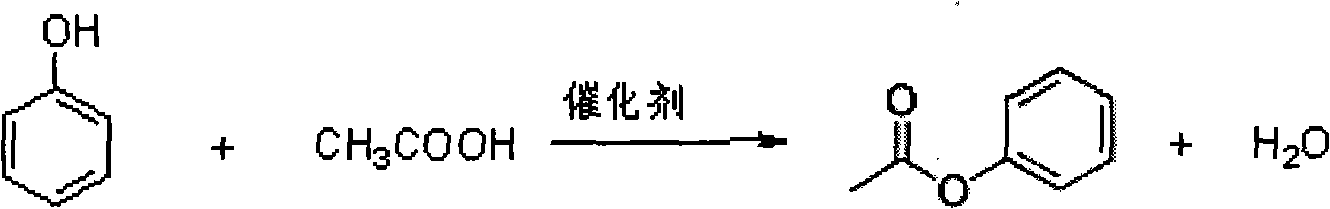

Login to View More Abstract

The invention discloses a method for preparing phenylacetate. The method comprises the following steps of: 1, mixing phenol and acetic acid in a molar ratio of 1:1.1, andsimultaneously adding the mixture into pyridine propyl sulfonic acid ionic liquid, wherein the ratio of the pyridine propyl sulfonic acid ionic liquid to the mixture of the phenol and the acetic acid is 1ml:1.05mol; 2, heating the mixed solution in oil bath, wherein the temperature is controlled to be between 120 and 130 DEG C; and 3, refluxing for 2 to 6 hours, performing distillation to remove the unreacted phenol and acetic acid, and collecting the phenylacetate separated at the temperature of between 190 and 195 DEG C. The method has the advantages that: the pyridine propyl sulfonic acid ionic liquid is used as a catalyst; the use of a solvent is avoided; the operation is simple and safe; the production cost is low; and the industrialization of phenylacetate can be realized easily.

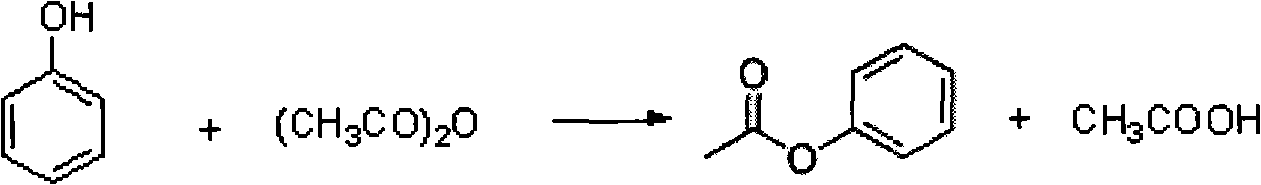

Description

technical field The present invention relates to a kind of preparation method of ester, particularly a kind of preparation method of phenyl acetate. Background technique The preparation method of existing phenyl acetate mainly contains: (1) Prepared by reacting sodium phenate with acetic anhydride. Heat phenol and acetic anhydride to boiling, reflux for 3 hours, wash with water, alkali, and water in sequence after cooling, and dry over anhydrous sodium sulfate, distill and collect fractions at 190-195°C as phenyl acetate, with a yield of about 83%. This method has shortcomings such as severe corrosion of equipment and low utilization rate of equipment; the reactant acetic anhydride used has a pungent smell, and its vapor is tear gas, which belongs to low-toxicity chemicals; Thermal energy can cause combustion and explosion, and can react with strong oxidants; the production process is complicated and the price is high; when used to synthesize phenyl acetate, the utiliza...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C69/157C07C67/08B01J31/02

Inventor 黎良枝龚润曾段李平顾敏娜

Owner SHANGHAI QIBAO HIGH SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com