Water cooling tank of high-strength and high-modulus polyethylene fiber

A polyethylene fiber, high-strength and high-modulus technology, which is applied in the field of cooling water tanks for preparing high-strength and high-modulus polyethylene fiber jelly filaments, can solve problems such as difficulty in moving, inconvenient installation and maintenance, and water surface fluctuations, so as to ensure continuous reliability and improve product quality. The effect of quality, reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

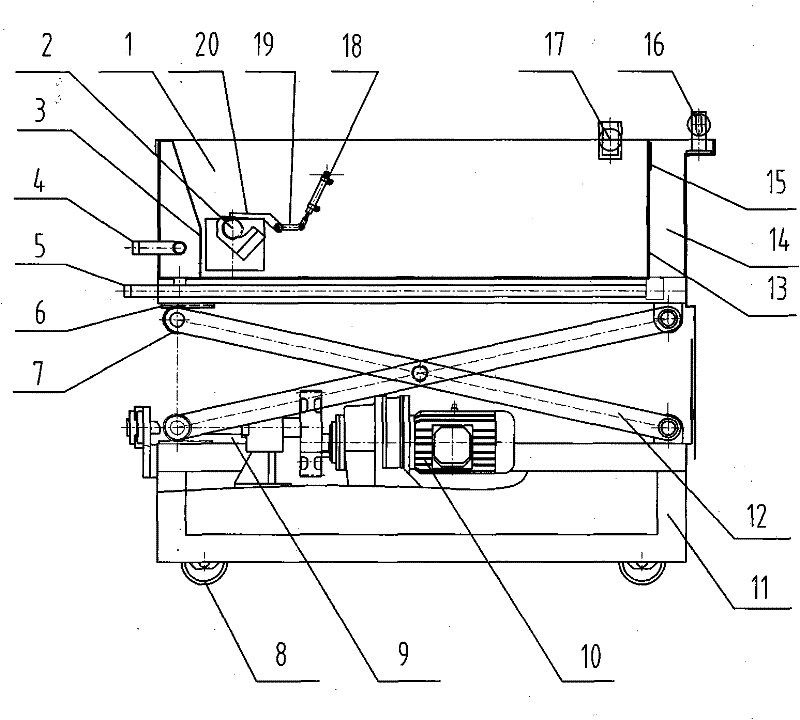

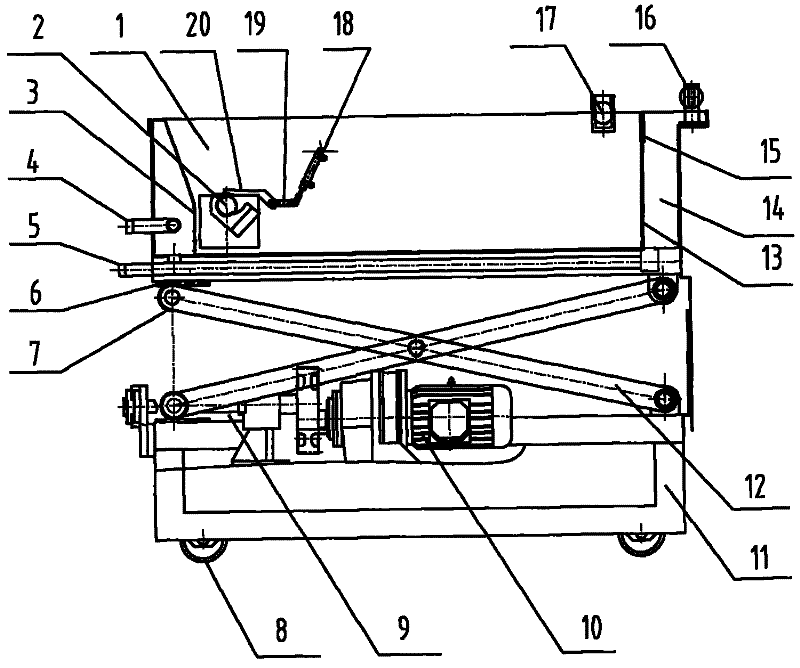

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] The high-strength and high-modulus polyethylene fiber cooling water tank of the present invention includes a tank body 1, a guide wire pressing roller 2 and a lifting mechanism. The front portion of the tank body 1 is provided with a water inlet pipe 4, and the inner cavity of the tank body 1 is separated by an inverted L-shaped partition 13 with a drainage groove 14, and a water outlet pipe 5 is provided in the drainage groove 14. The upper part of the partition plate 13 An overflow hole is provided to allow excess water in the tank body 1 to overflow into the drainage tank 14; a water level regulating plate 15 is provided at the overflow hole of the above-mentioned partition 13 to pass through the overlapping of the water level regulating plate 15 and the overflow hole. , thereby adjusting the water level in the tank body 1. The front part of the cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com