Ultrathin bendable natural stone composite board and manufacture method thereof

A production method and composite board technology, which are applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of broken stone slabs, excessive scraps, waste of stone materials, etc., so as to facilitate production and construction, save natural resources, reduce The effect of product cost and weight

Active Publication Date: 2010-08-25

佛山市利铭蜂窝复合材料有限公司

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method produces a lot of leftovers, which is a waste of stone, and the minimum plate thickness is generally required to be 35mm larger. If it is less than 35mm, the stone plate is prone to breakage during processing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Minimum bending radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

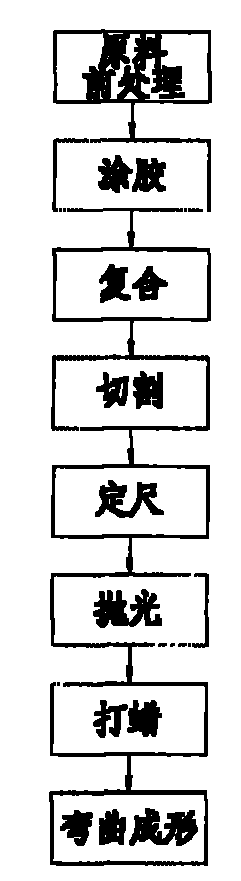

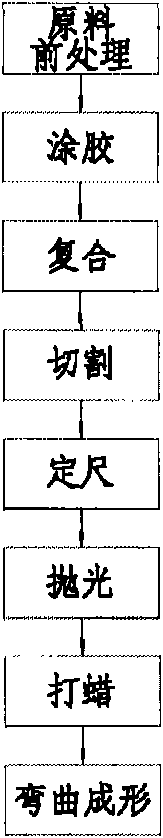

The invention belongs to the technical field of building materials, in particular to an ultrathin bendable natural stone composite board and a manufacture method thereof. The stone composite board comprises a wax layer, a stone layer, a rubber layer and a metal substrate layer in sequence from the outside to the inside, wherein the wax layer is an oil wax layer; the thickness of the stone layer is 1-1.5 mm; the minimum bending radius of the stone composite board is 500-600 mm; the rubber layer is made of polyurethane adhesives, the thickness of which is 0.15-0.2 mm and the elongation percentage of which is larger than 120 percent; the metal substrate layer is a No. 5052 alloy aluminium plate, the thickness of which is 0.8-1 mm. The manufacture method comprises the following steps of raw material pretreatment, gluing, compounding, cutting, side length and thickness determination, polishing, waxing, bending forming and the like. The invention improves the processing efficiency, reduces the wastes of stone, and can achieve the good effects of saving natural resources, reducing product cost and quality and facilitating manufacture and construction.

Description

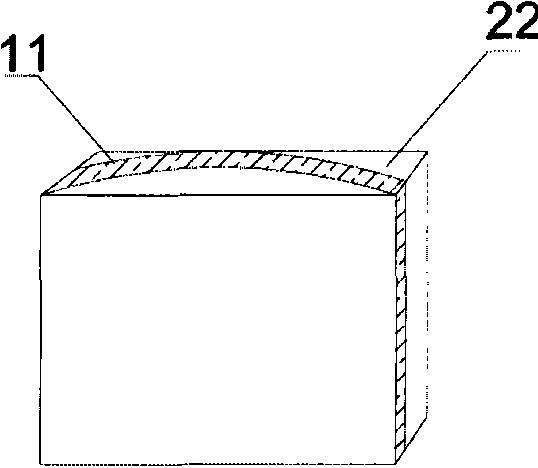

Ultra-thin bendable natural stone composite board and manufacturing method thereof technical field The invention belongs to the technical field of building materials, and in particular relates to an ultra-thin bendable natural stone composite board and a manufacturing method thereof. The stone composite board is used for surface decoration of cylindrical surfaces or curved walls of buildings. Background technique It is often necessary to decorate various natural marble, granite and other stone slabs on the exterior and interior surfaces of buildings. Among them, for the stone slabs used for the columns and curved walls of buildings, as shown in Figure 1, the traditional method is to directly place stone panels on the stone. Curved stone slabs are cut out of the raw material according to the required radian, wherein the curved stone slab 11 and the stone raw material 22 are shown. This method produces a lot of leftovers, which is a waste of stone, and the minimum plate thic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04F13/073E04F13/077B28D1/30

Inventor 区廷杰

Owner 佛山市利铭蜂窝复合材料有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com