Waste heat recovery system of petrochemical heating furnace

A waste heat recovery system and petrochemical technology, applied in the field of petrochemical industry, can solve the problems of single replacement, low efficiency of heating furnace, easy dust accumulation, etc., and achieve the effect of increasing flexibility, improving thermal efficiency and protecting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

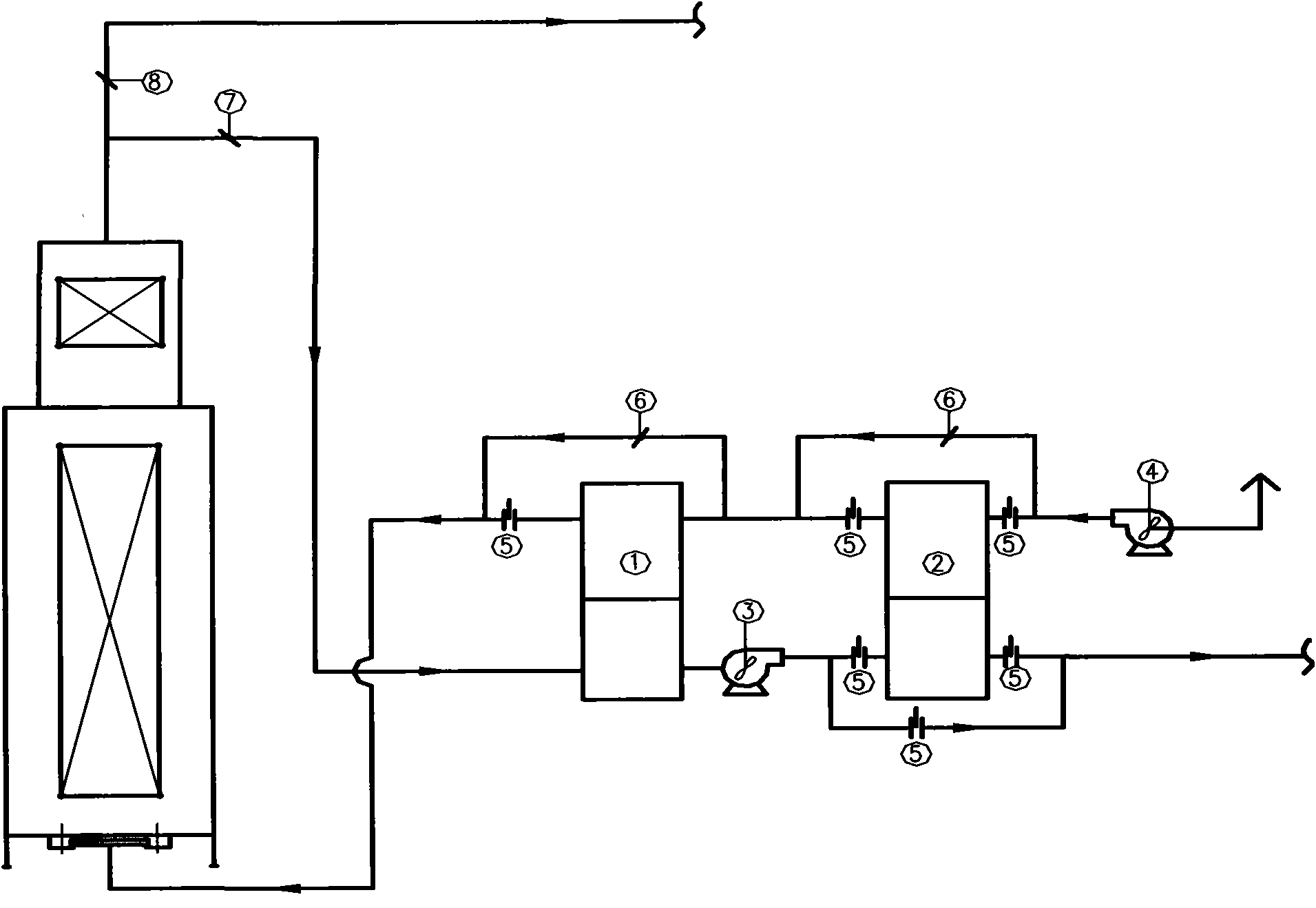

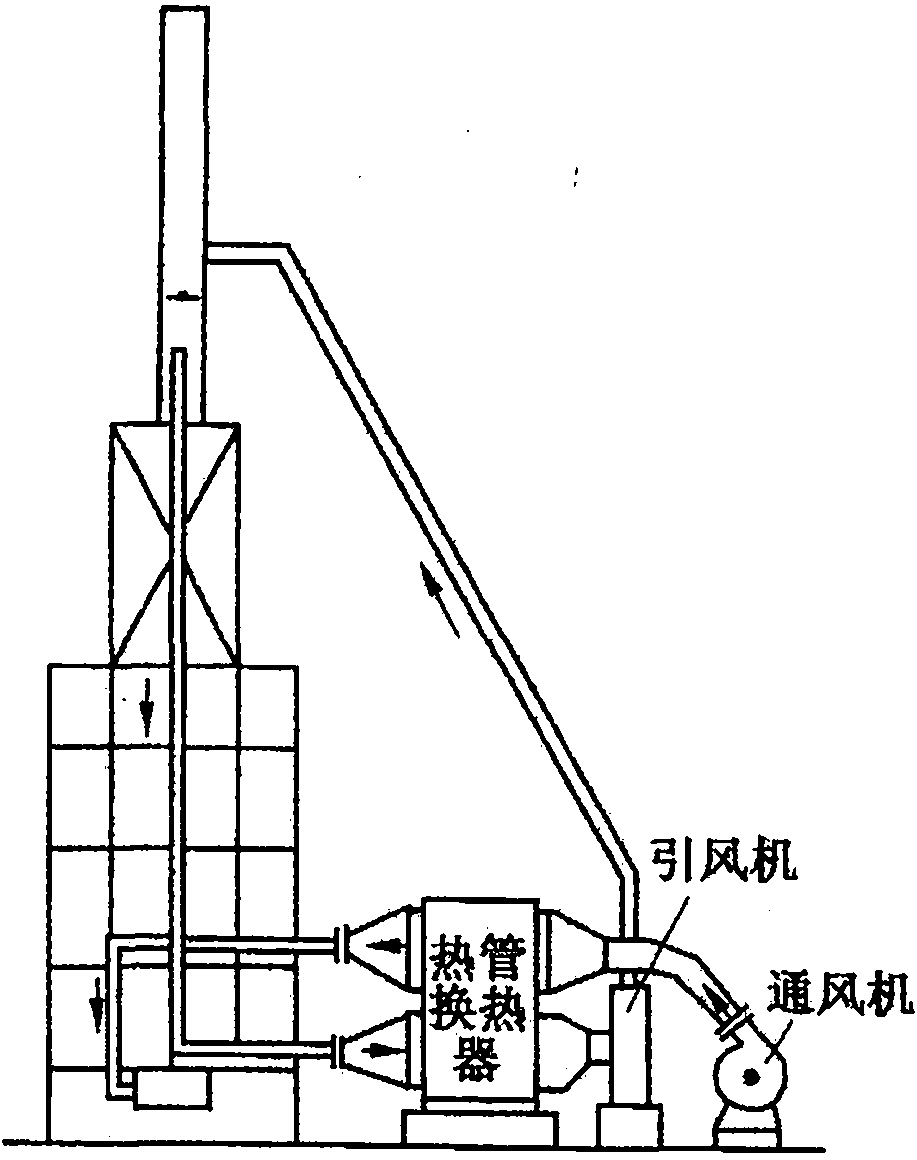

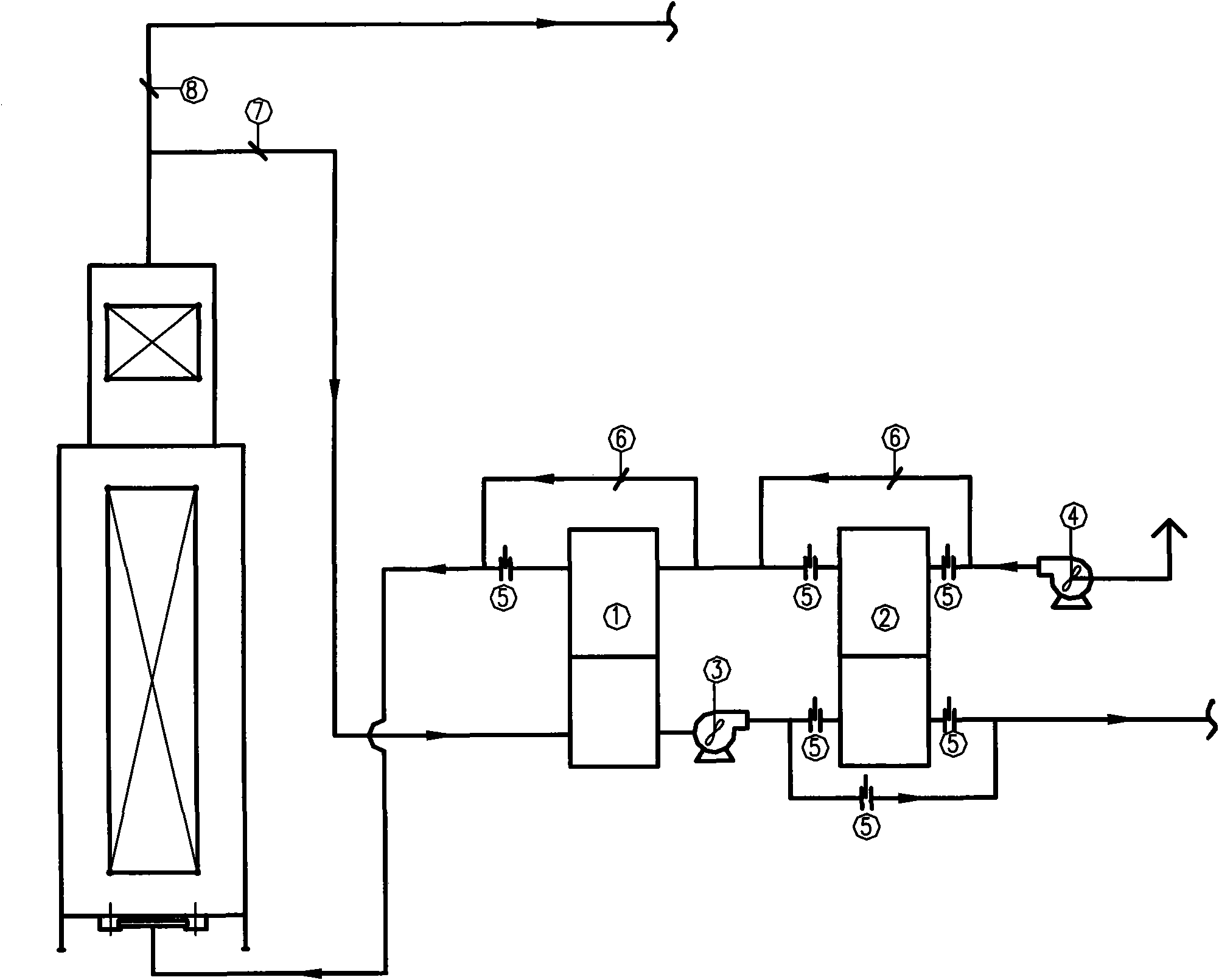

[0022] As shown in Fig. 2, a petrochemical heating furnace waste heat recovery system includes an air preheater, an induced draft fan 3, and a blower fan 4.

[0023] In order to adapt to different working conditions, the air preheater includes a high temperature section air preheater 1 and a low temperature section air preheater 2 . Specifically, the flue gas outlet temperature of the air preheater 1 in the high temperature section is 160-170 degrees, and a tubular or heat pipe or plate air preheater is adopted; the flue gas of the air preheater 2 in the low temperature section The outlet temperature is equal to or lower than 100 degrees, using plate or cast iron plate tube or glass tube or enamel tube.

[0024] The induced draft fan 3 is arranged between the air preheater 1 of the high temperature section and the air preheater 2 of the low temperature section, so that the induced draft fan 3 can be kept running at a temperature above the dew point for a long time, thereby ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com