Production system and production method for manufacturing recordable Blue-ray disc

A technology of a production system and a production method, which is applied in the direction of optical recording/reproduction, optical record carrier, optical record carrier manufacturing, etc., can solve the problems of reduced output, increased production cost of Blu-ray discs, and data reproduction errors, etc., to achieve improved Hardness, reduced reading and writing errors, and easy data reading and writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

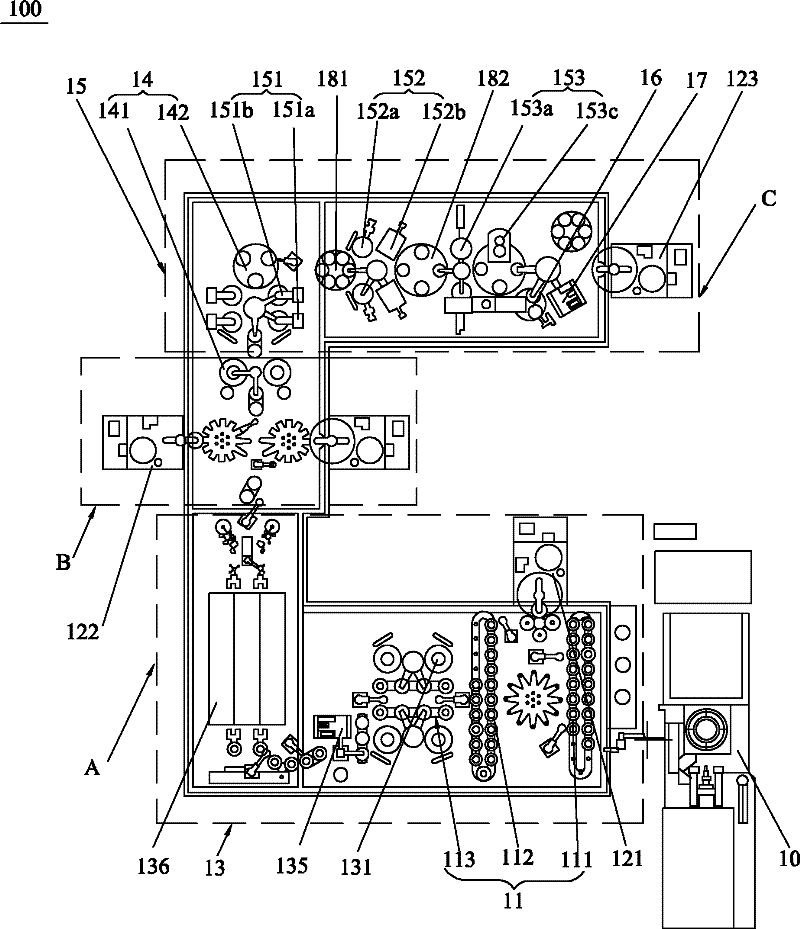

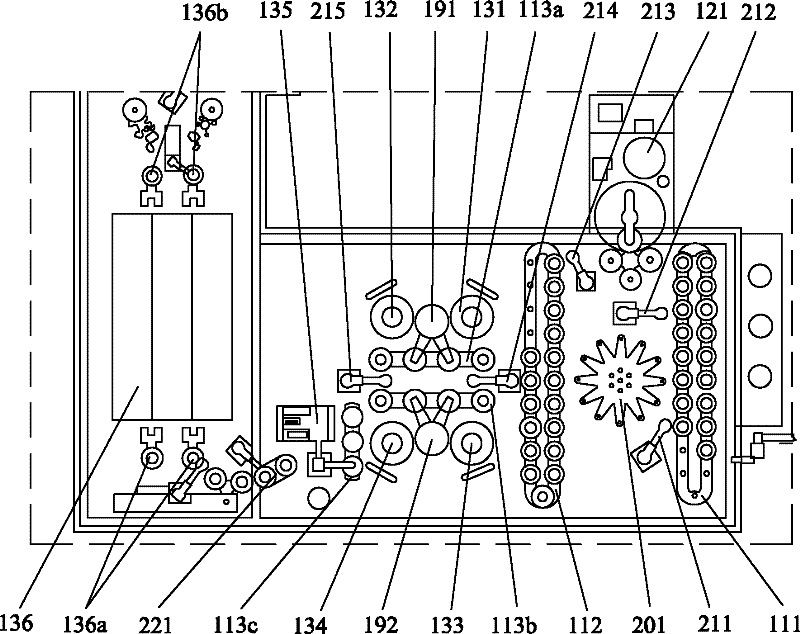

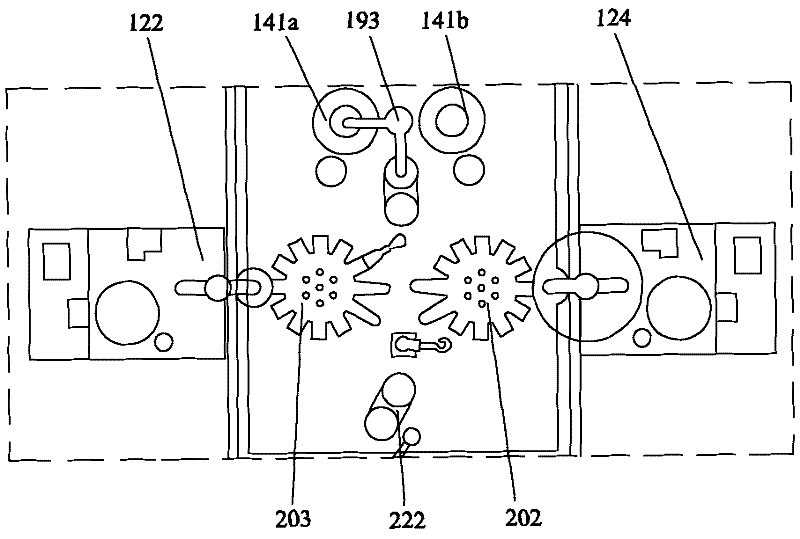

[0036] Such as figure 1 As shown, the production system 100 of the present invention for manufacturing Blu-ray recording discs is connected with an injection molding machine 10 for injection molding substrates, which includes a conveyor belt 11, a first sputtering station 121, a second sputtering station 122, and a dye coating mechanism 13 , spin coating curing mechanism 15, edge cleaning mechanism 14 and detection mechanism 17, the first sputtering station 121 is used for sputtering metal reflection layer, the second sputtering station 122 is used for sputtering buffer layer, dye coating mechanism 13 is used for The dye is spin-coated and detected and dried. The spin-coating curing mechanism 15 is used to spin-coat the protective layer and cure it. The edge-cleaning mechanism 14 is used to clean the excess material aroun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com