Anode for a solid electrolytic capacitor containing a non-metallic surface treatment

A technology of solid electrolytic capacitors and solid electrolyte layers, applied in the field of forming capacitor anodes, forming solid electrolytic capacitors, and solid electrolytic capacitors, can solve problems such as unstable leakage current and limited applications

Inactive Publication Date: 2010-08-25

AVX CORP

View PDF37 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This leads to unstable leakage current under accelerated temperature and voltage loads, which will limit the application of this type of capacitor in the high voltage field

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

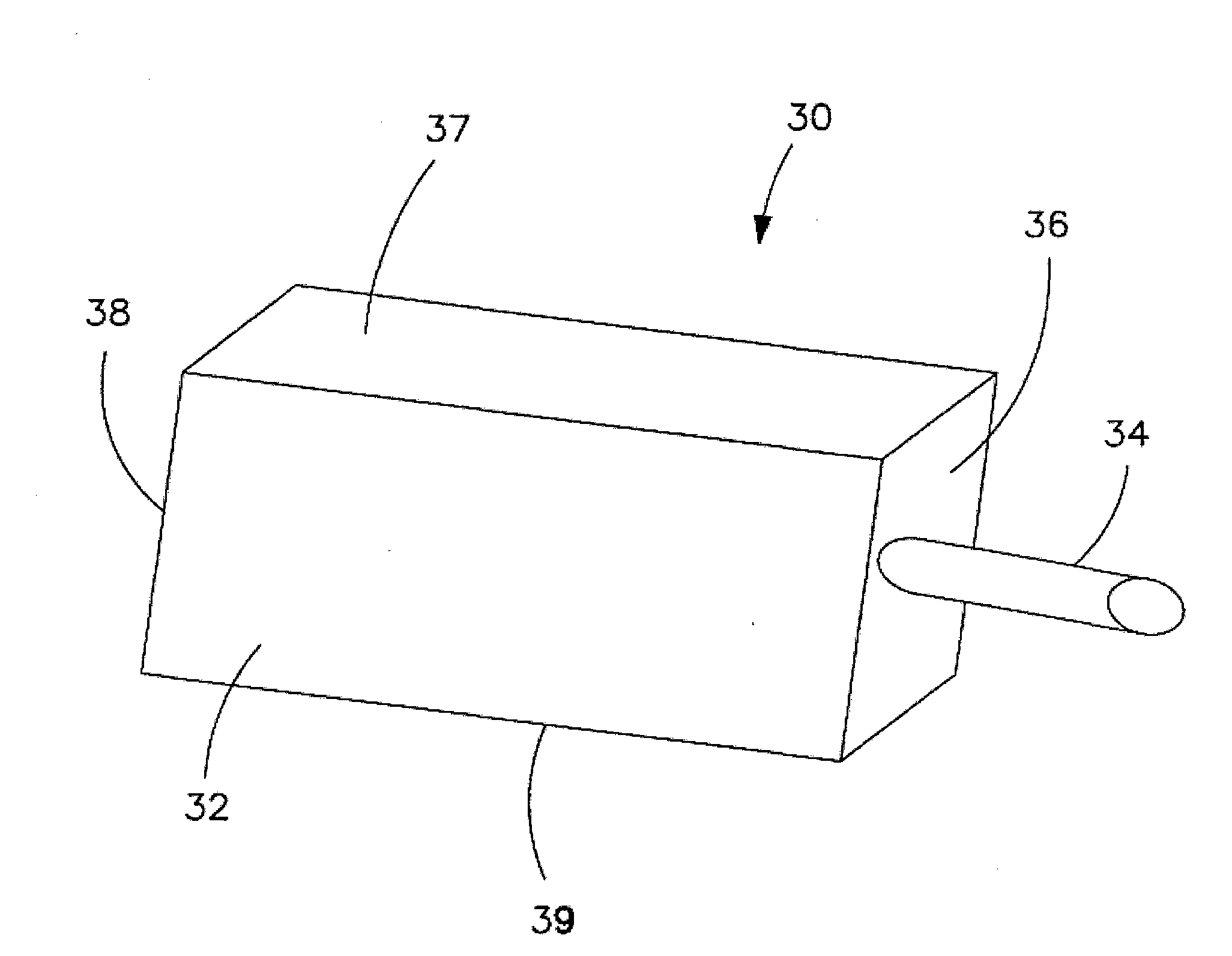

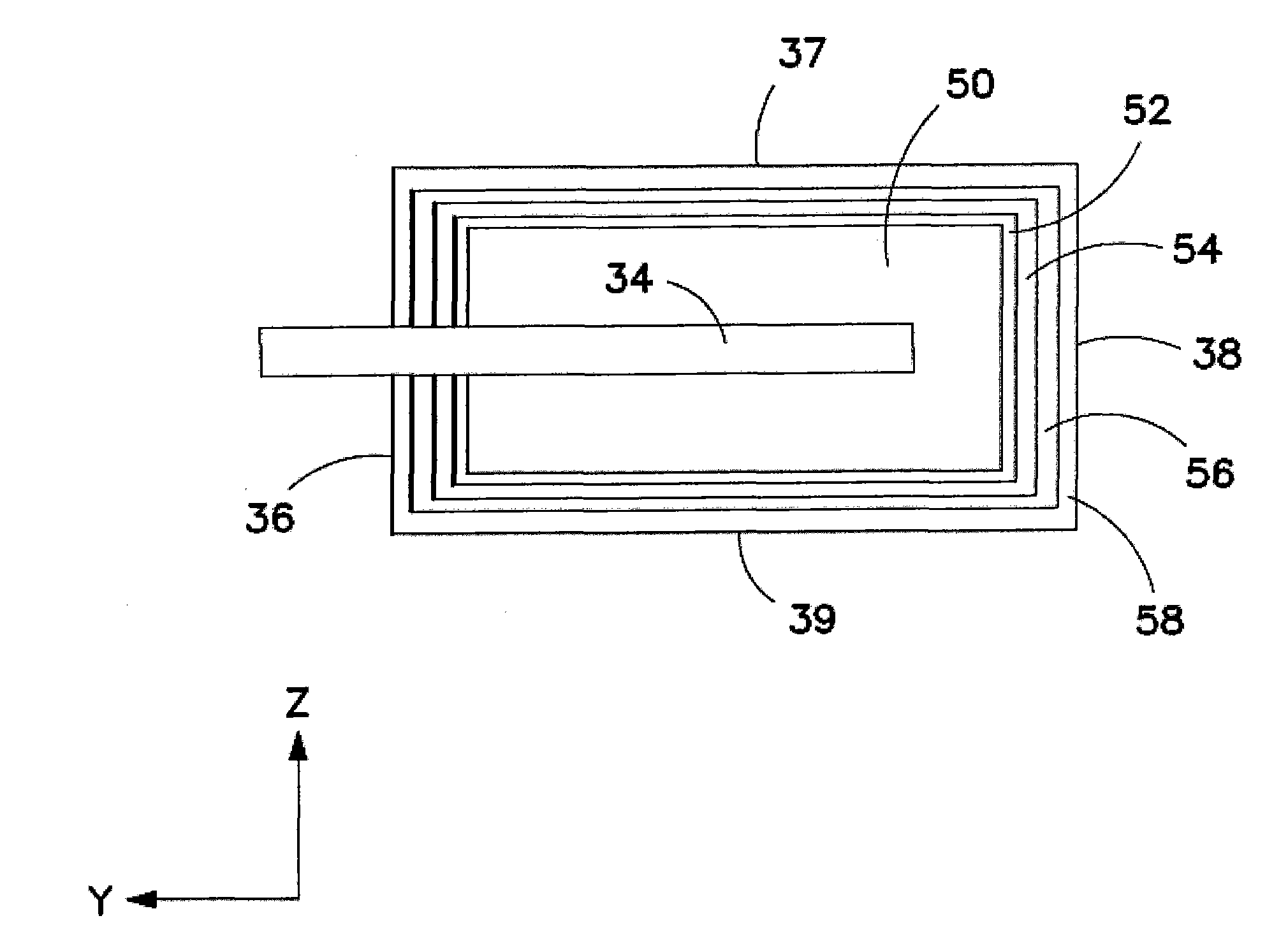

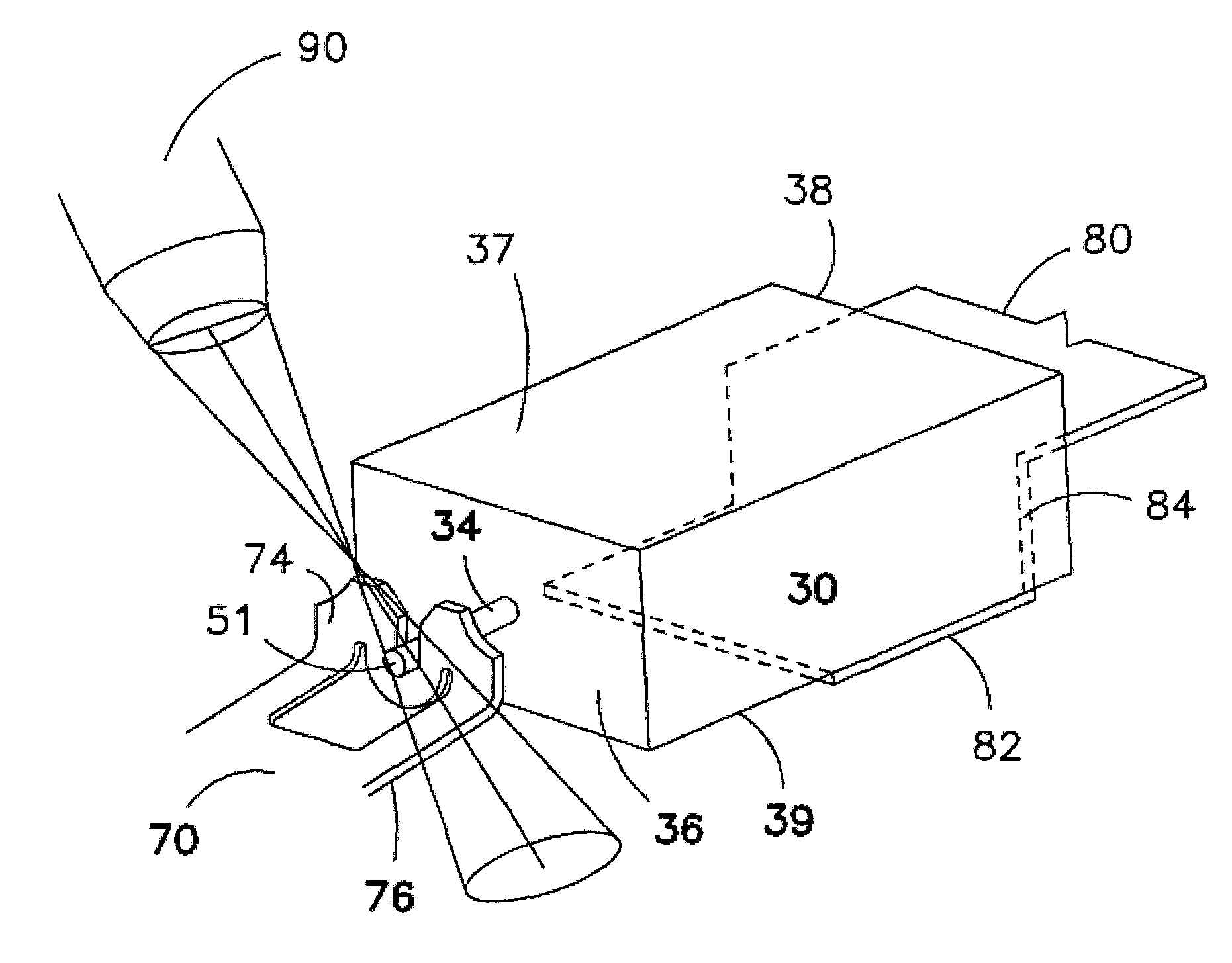

A solid electrolytic capacitor comprises an anode, a dielectric layer overlying the anode; and a cathode that contains a solid electrolyte layer overlying the dielectric layer. The anode comprises a porous, sintered body that defines a surface. The body is treated so that the surface contains a non-metallic element having a ground state electron configuration that includes five or more valence electrons at an energy level of three or more (e.g., phosphorous).

Description

Anodes of Solid Electrolytic Capacitors Containing Non-Metallic Surface Treatment Background technique Electrolytic capacitors are typically formed from a valve action material that can be oxidized to form a dielectric layer. Typical valve action materials are niobium and tantalum. Capacitors have also been developed to use anodes formed from conductive niobium oxide and niobium pentoxide dielectrics. Despite the benefits of such niobium oxide capacitors, they typically have limited application at high voltages (eg, rated voltages of 16, 20 or 35 volts) because of the relatively low breakdown strength of the dielectric. In general, as the charge and voltage on the capacitor grow, the free electrons will eventually accelerate to a speed at which they can release additional electrons during an avalanche breakdown of collisions with neutral atoms or molecules, which occurs fairly suddenly (usually on the order of nanoseconds), thereby forming a conductive path through the mat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01G9/15H01G9/04H01G9/08H01G9/14

CPCH01G9/0032H01G9/15H01G9/052H01G9/07H01G9/04H01G9/042H01G9/0525H01G9/012

Inventor 托马什·卡尔尼克

Owner AVX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com