Orthopedic clamp for microwave tube grid and orthopedic method thereof

A microwave tube and grid technology, which is applied in the field of orthopedic fixtures for microwave tube grids, can solve problems affecting the performance of grid-controlled microwave tubes, affecting the quality of grid-controlled electron guns, and poor grid accuracy, achieving good application promotion value and structure Simple, quality-assured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

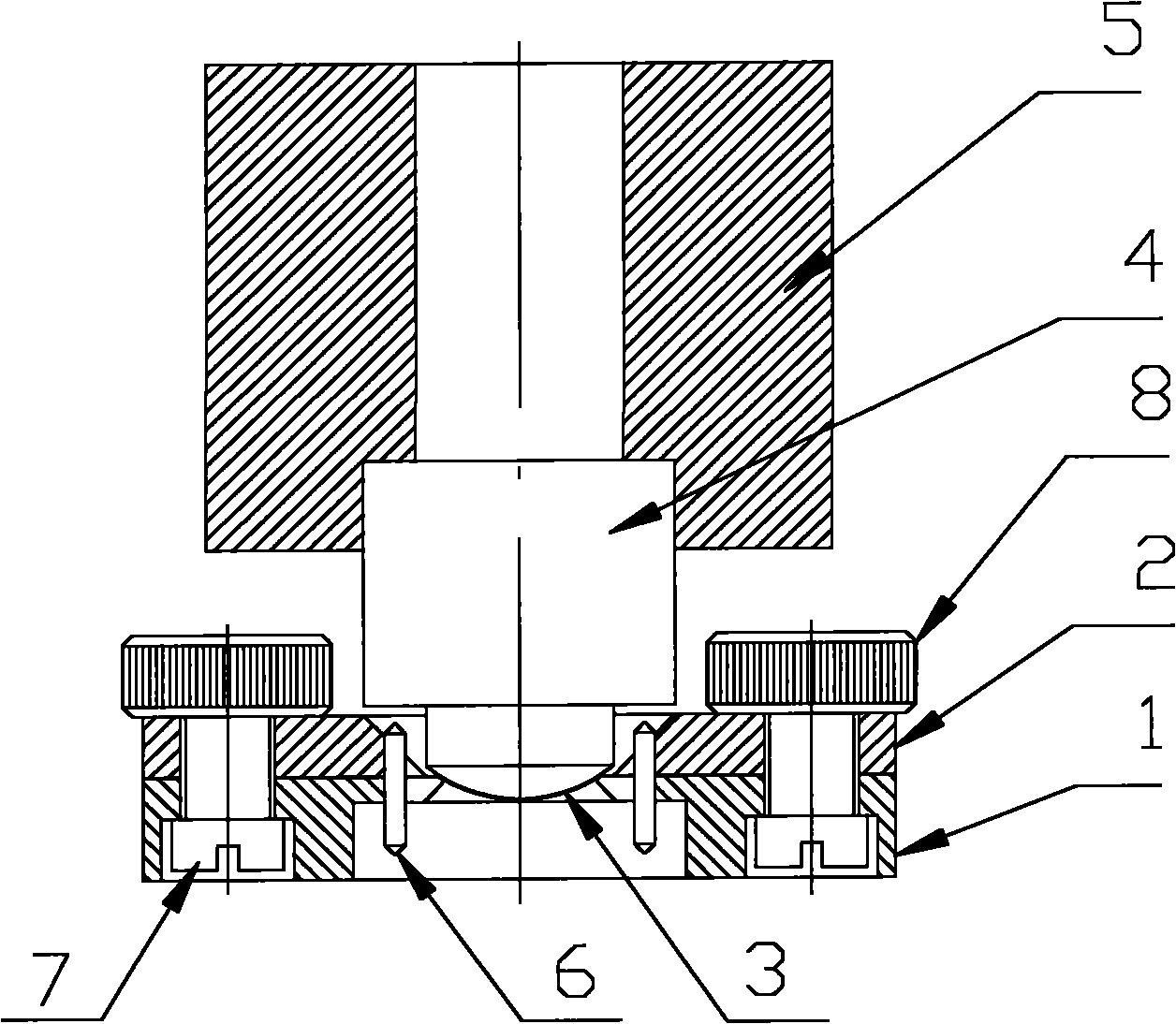

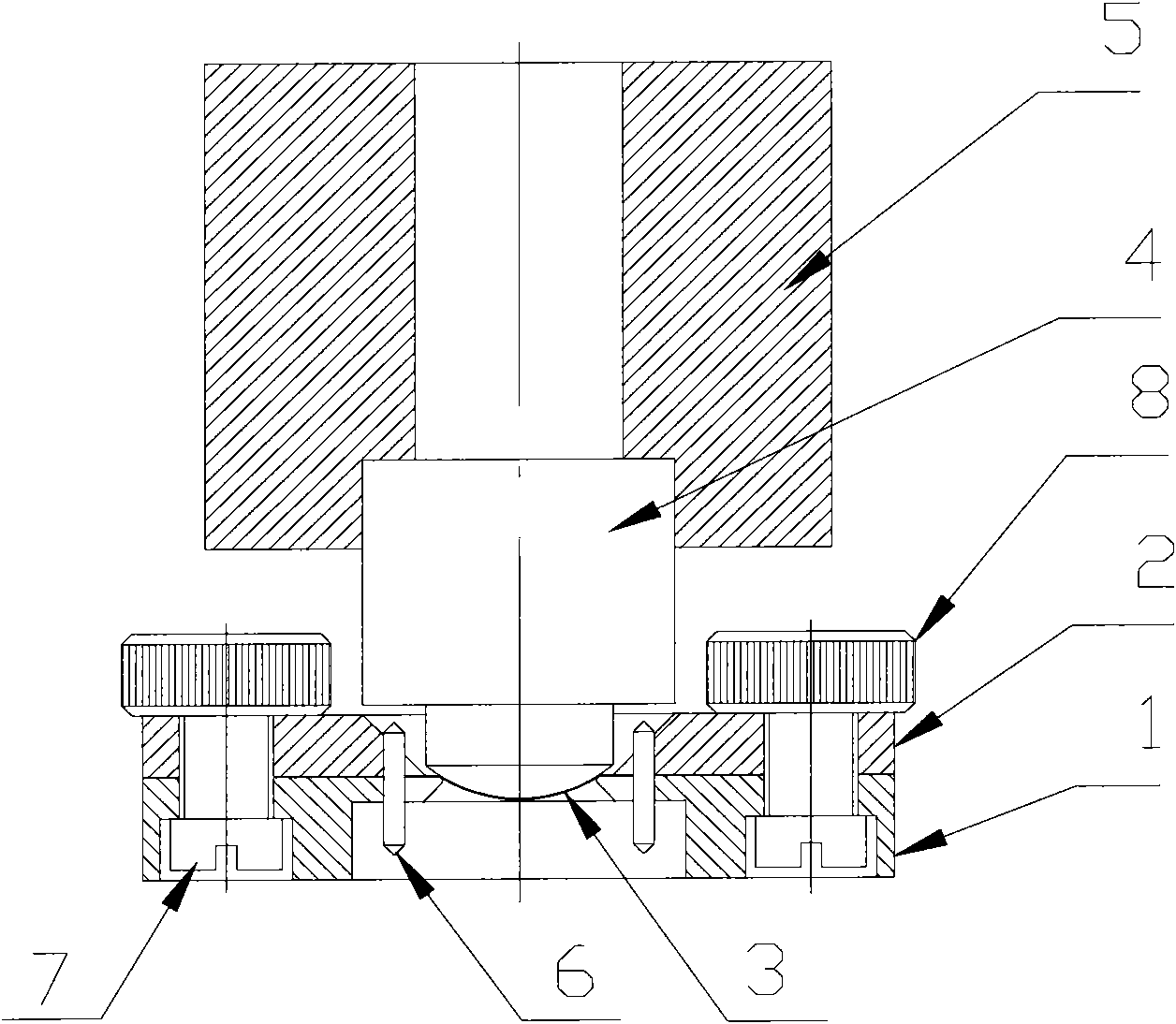

[0023] Figure 1 is a structural schematic diagram of the orthopedic clamp for the microwave tube grid of the present invention in use. The orthopedic clamp for the microwave tube grid includes a base 1 and a pressing plate 2 directly above the base 1, and a male mold 4 A spherical surface is provided, and through the spherical surface and the base 1, the contact surface of the male mold 4 and the base 1 is a smooth spherical surface; the pressure plate 2 is provided with a hollow part that matches the spherical surface, and the male mold 4 is provided with The opposite end of the spherical surface is matched with the pressing block 5. The end of the pressing block 5 and the male mold 4 is provided with positioning holes to ensure a good fit with the male mold 4; the base 1 and the pressing plate 2 are provided with coaxial positioning pin holes, and The positioning and fixing are carried out by the positioning pin 6, and the base 1, the pressing plate 2 and the positioning pin 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com