Process for producing natto powder

A production process, natto powder technology, applied in the biological field, can solve the problems of nattokinase, such as high cost, difficult storage, and difficult marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of production technology of natto powder, its process comprises:

[0018] (1) Solid fermentation: Soak 1 kg of selected soybeans in running water for 20 hours, cook at 0.1Mpa for 30 minutes; inoculate with Bacillus natto after cooling, the inoculation amount is 1%; ferment, ferment at 37°C for 18 hours after inoculation; Get fresh natto;

[0019] (2) liquid fermentation: prepare culture medium, wherein get soybean powder 12% by weight percentage, glucose 7.2%, dextrin 4.8%, NaCl 0.4%, surplus is water, and pH is 7.0; Bacillus natto is inoculated, inoculum size is 5%; fermented, fermented at 37°C for 24 hours after inoculation; take the fermentation broth for later use;

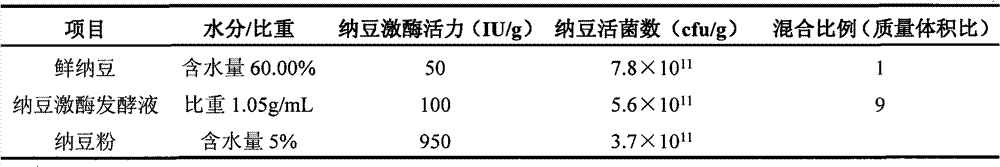

[0020] (3) adopt fiber plate method and colony plate counting method to measure the nattokinase activity and the number of natto bacteria of solid fermentation product and liquid fermentation product, to obtain nattokinase activity is 1010IU / g natto powder, its preparation is specific As shown ...

Embodiment 2

[0032] A kind of production technology of natto powder, its process comprises:

[0033] (3) Solid fermentation: Soak 1 kg of selected soybeans in running water for 20 hours, cook at 0.1Mpa for 30 minutes; inoculate with Bacillus natto after cooling, the inoculation amount is 1%; ferment, in 18 hours after inoculation; get fresh sodium bean;

[0034] (4) liquid fermentation: prepare culture medium, wherein get soybean powder 12% by weight percentage, glucose 7.2%, dextrin 4.8%, NaCl 0.6%, surplus is water, and pH is 7.2: bacillus natto is inoculated, inoculum size is 5%; fermented, fermented at 37°C for 24 hours after inoculation; take the fermentation broth for later use;

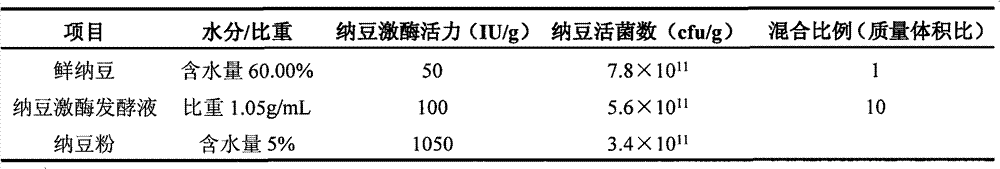

[0035] (3) adopt fiber plate method and colony plate counting method to measure the nattokinase activity and the number of natto bacteria of solid fermentation product and liquid fermentation product, to obtain nattokinase activity is the natto powder of 1115IU / g, its preparation is specific As shown in t...

Embodiment 3

[0047] A kind of production technology of natto powder, its process comprises:

[0048] (5) Solid fermentation: Soak 1 kg of selected soybeans in running water for 20 hours, cook at 0.1Mpa for 30 minutes; inoculate with Bacillus natto after cooling, the inoculation amount is 1%; ferment, ferment at 37°C for 18 hours after inoculation; Get fresh natto;

[0049] (6) liquid fermentation: prepare culture medium, wherein get soybean powder 12% by weight percentage, glucose 7.2%, dextrin 4.8%, NaCl 0.5%, surplus is water, and pH is 6.8: bacillus natto is inoculated, inoculum size is 5%; fermented, fermented at 37°C for 24 hours after inoculation; take the fermentation broth for later use;

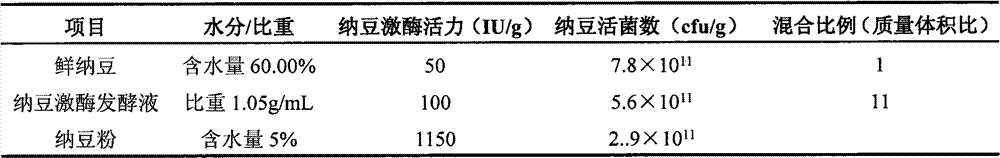

[0050] (3) adopt fiber plate method and colony plate counting method to measure the nattokinase activity and the number of natto bacteria of solid fermentation product and liquid fermentation product, to obtain nattokinase activity is the natto powder of 1220IU / g, its preparation is specific as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com