Servo double-arm clamping type bag feeding manipulator with slotting tools

A manipulator and clamp technology, applied in the field of automatic packaging machinery, can solve the problems of shock and vibration, fast bag loading, etc., and achieve the effects of strong dust resistance, improved bag loading ability, and reduced product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific drawings and embodiments.

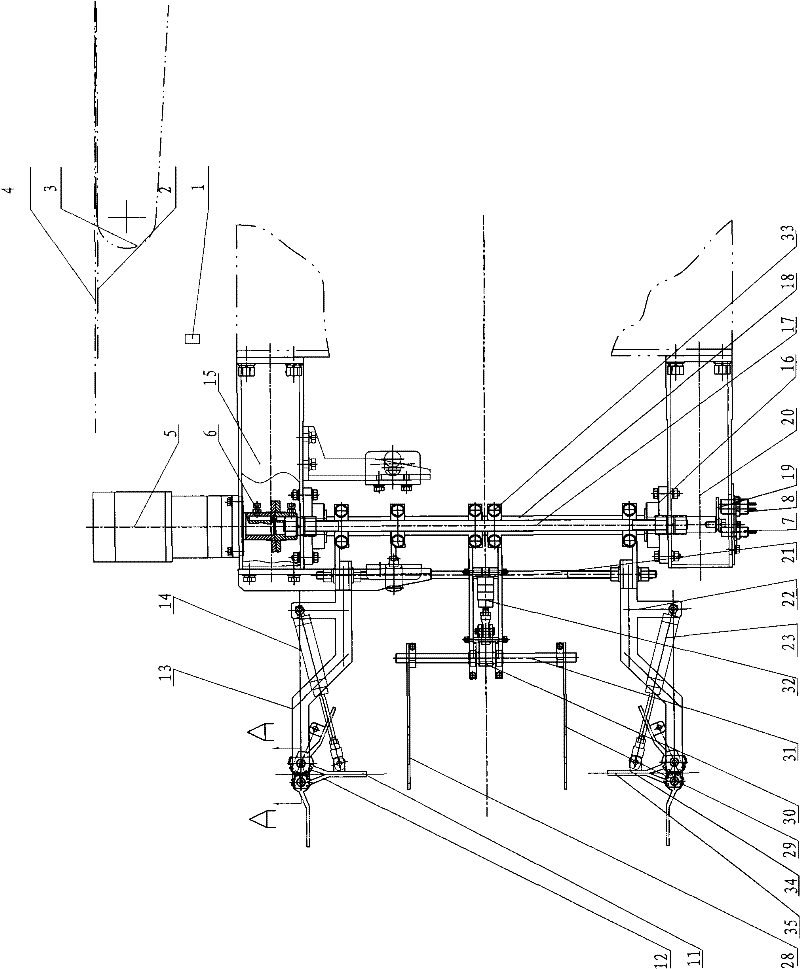

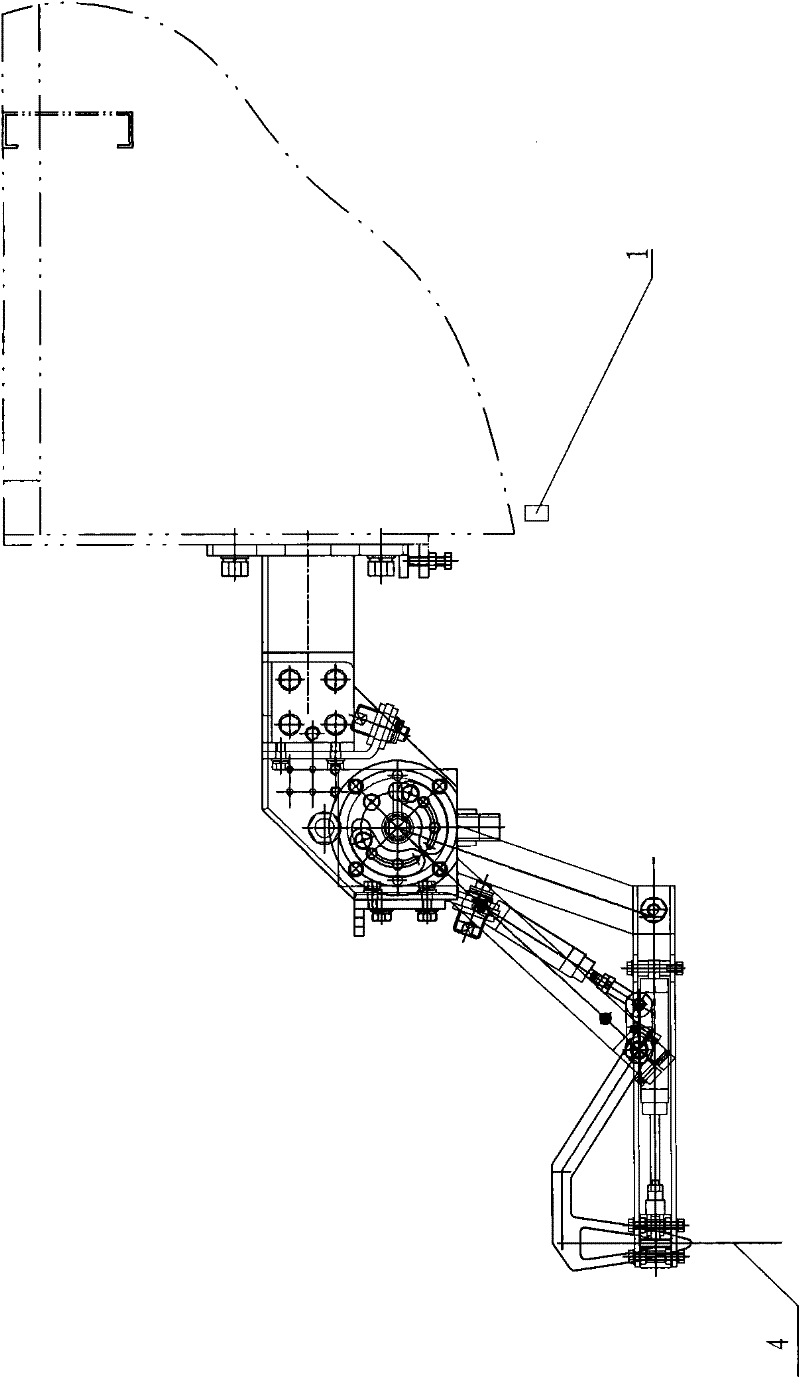

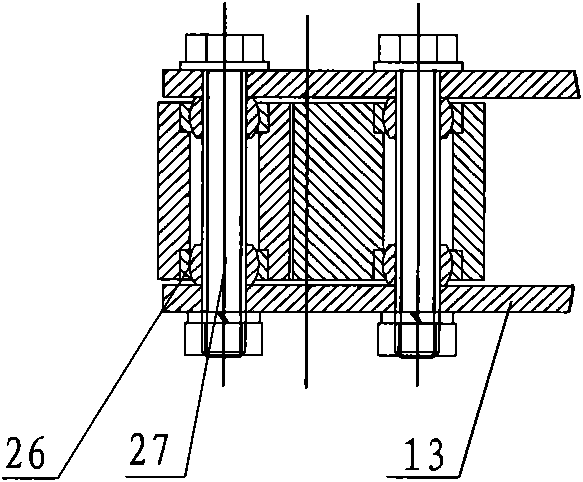

[0024] As shown in the figure, the present invention is mainly composed of through-beam photoelectricity 1, fully automatic bagging machine support platform 2, bag feeding synchronous belt 3, packaging bag 4, servo motor 5, coupling 6, bag clamping position proximity switch 7 , Proximity switch 8 to be clamped, small gear clamp 11, large gear clamp 12, left upper bag arm 13, first cylinder 14, left base frame 15, belt seat bearing 16, rotating shaft 17, connecting rod 18, trigger piece 19. Right base frame 20, screw rod 21, right upper bag arm 22, second cylinder 23, radial joint bearing 26, bolt shaft 27, left slotting knife 28, right slotting knife 29, transmission part 30, slotting knife shaft 31, the third cylinder 32, mounting frame 33, right side large gear clamp 34 and right side pinion gear clamp 35 and other parts constitute.

[0025] The servo double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com