Alkaline soil corrosion-resistant steel for hot-rolled U-shaped steel sheet pile and manufacture method thereof

A technology of soil corrosion and steel sheet piles, applied in metal rolling, manufacturing converters, etc., to achieve the effects of simple production process, favorable promotion, and excellent corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

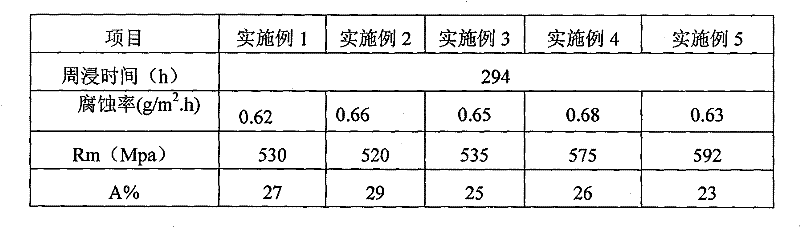

Examples

Embodiment 1

[0023] Alkaline soil corrosion-resistant steel for hot-rolled U-shaped steel sheet piles, its chemical composition and weight percentage are: C 0.15%, Mn 0.8%, Si 0.10%, S 0.020%, P 0.0195%, Cu 0.2%, Ni 0.1 %, the rest is Fe and unavoidable impurities.

[0024] A method for producing steel for hot-rolled U-shaped steel sheet piles resistant to alkaline soil corrosion, the steps of which are:

[0025] 1) Smelting and refining in a converter: the controlled final slag basicity R is 2;

[0026] 2) Continuous casting: In order to prevent the molten steel from tumbling and slag rolling during casting, the depth of the long nozzle inserted into the mold is controlled at 100 mm;

[0027] 3) Heating the continuous casting slab to 1050-1060°C;

[0028] 4) Carry out rolling: control the rolling start temperature at 1020-1030° C., and roll at 1082° C. below the melting point of copper at 1083° C.

Embodiment 2

[0030] Alkaline soil corrosion-resistant steel for hot-rolled U-shaped steel sheet piles, its chemical composition and weight percentage are: C 0.175%, Mn 0.91%, Si 0.19%, S 0.0195%, P 0.0192%, Cu 0.28%, Ni 0.14 %, the rest is Fe and unavoidable impurities.

[0031] A method for producing steel for hot-rolled U-shaped steel sheet piles resistant to alkaline soil corrosion, the steps of which are:

[0032] 1) Smelting and refining in a converter: the controlled final slag basicity R is 2.9;

[0033] 2) Continuous casting: In order to prevent the molten steel from tumbling and slag rolling during casting, the depth of the long nozzle inserted into the mold is controlled at 150 mm;

[0034] 3) Heating the continuous casting slab to 1065-1080°C;

[0035] 4) Carry out rolling: control the rolling start temperature at 1035-1050° C., and roll at 1080° C. below the melting point of copper at 1083° C.

Embodiment 3

[0037] Alkaline soil corrosion-resistant steel for hot-rolled U-shaped steel sheet piles, its chemical composition and weight percentage are: C 0.21%, Mn 1.1%, Si 0.296%, S 0.0192%, P 0.0192%, Cu 0.36%, Ni 0.18% , and the rest are Fe and unavoidable impurities.

[0038] A method for producing steel for hot-rolled U-shaped steel sheet piles resistant to alkaline soil corrosion, the steps of which are:

[0039] 1) Smelting and refining in a converter: the controlled final slag basicity R is 3.8;

[0040] 2) Continuous casting: In order to prevent the molten steel from tumbling and slag rolling during casting, the depth of the long nozzle inserted into the mold is controlled at 200 mm;

[0041] 3) Heating the continuous casting slab to 1095-1105°C;

[0042] 4) Carry out rolling: control the rolling start temperature at 1055-1070° C., and the rolling temperature is rolled at 1075° C. below the melting point temperature of copper of 1083° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com