A laser direct deposition preparation method and device for the working layer of a metallurgical hot roll

A technology of working layer and hot roll, which is applied in the application field of laser technology to achieve the effect of good application prospect, prolonging service life and reducing scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

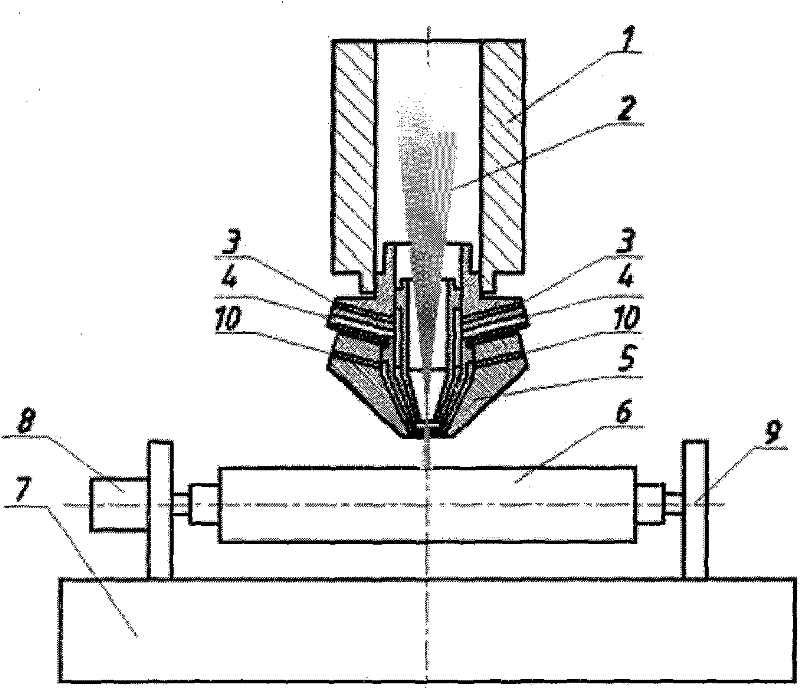

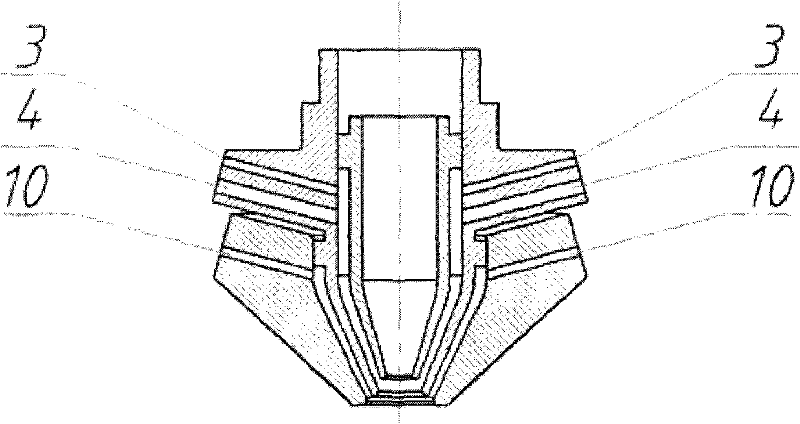

Method used

Image

Examples

Embodiment 1

[0042] Example 1: High-speed steel-like powder

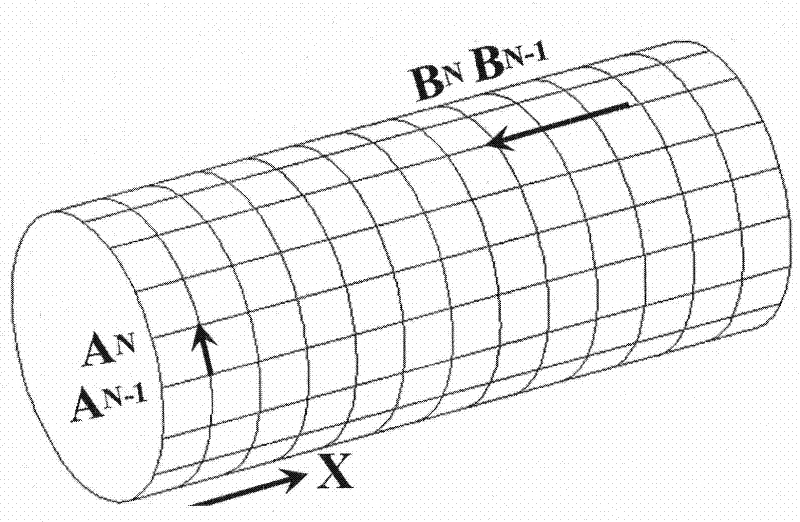

[0043] Use gasoline, alcohol, etc. to remove oil and decontamination solvents to remove oil and rust on the surface of the roller core, and then use sandpaper to polish the surface of the roller core to further remove dirt and facilitate the deposition of the deposition layer; then put the mechanically mixed powder to be deposited into the powder feeding system, adjust the shielding gas, powder feeding gas flow rate and powder flow control system to obtain the required powder flow; open the CO 2 Laser for powder deposition on the surface of the roll core. Such as image 3 As shown, first deposit along the axial direction of the roll (X direction), and then pass A N and previous pass A N-1 Carry out overlapping, after depositing the entire roll side, start depositing along the roll circumference direction at the end point, the subsequent pass B N with previous pass B N-1 Carry out the overlap of the same overlap rate in the ...

Embodiment 2

[0045] Example 2: Co-based alloy composite powder

[0046] Use gasoline, alcohol, etc. to remove oil and decontamination solvents to remove oil and rust on the surface of the roller core, and then use sandpaper to polish the surface of the roller core to further remove dirt and facilitate the deposition of the deposition layer; then put the mechanically mixed powder to be deposited into the powder feeding system, adjust the shielding gas, powder feeding gas flow rate and powder flow control system to obtain the required powder flow; open the CO 2 Laser for powder deposition on the surface of the roll core. Such as image 3 As shown, first deposit along the axial direction of the roll (X direction), and then pass A N and previous pass A N-1 Carry out overlapping, after depositing the entire roll side, start depositing along the roll circumference direction at the end point, the subsequent pass B N with previous pass B N-1 Carry out the overlap of the same overlap rate in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com