Nickel-based superalloy/stainless steel gradient composite material based on laser near-net forming technology and preparation method of nickel-based superalloy/stainless steel gradient composite material

A nickel-based superalloy, laser near-net forming technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., to achieve the effect of rich raw material sources, simple preparation methods, and guaranteed overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

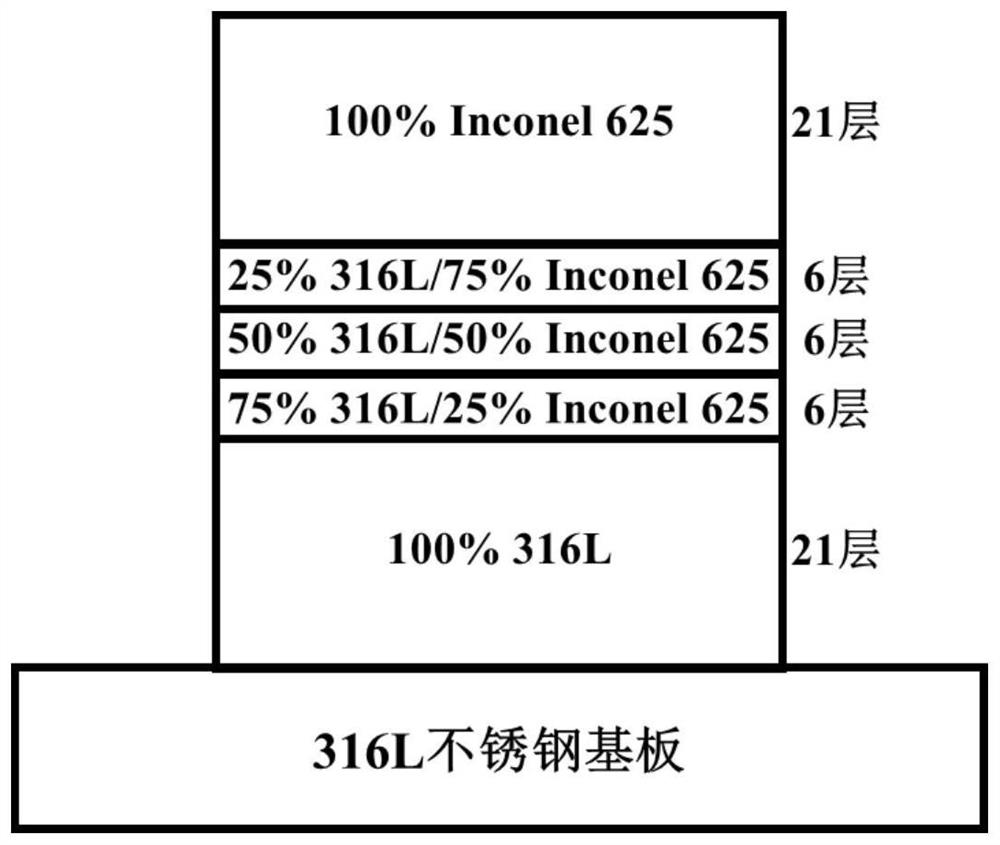

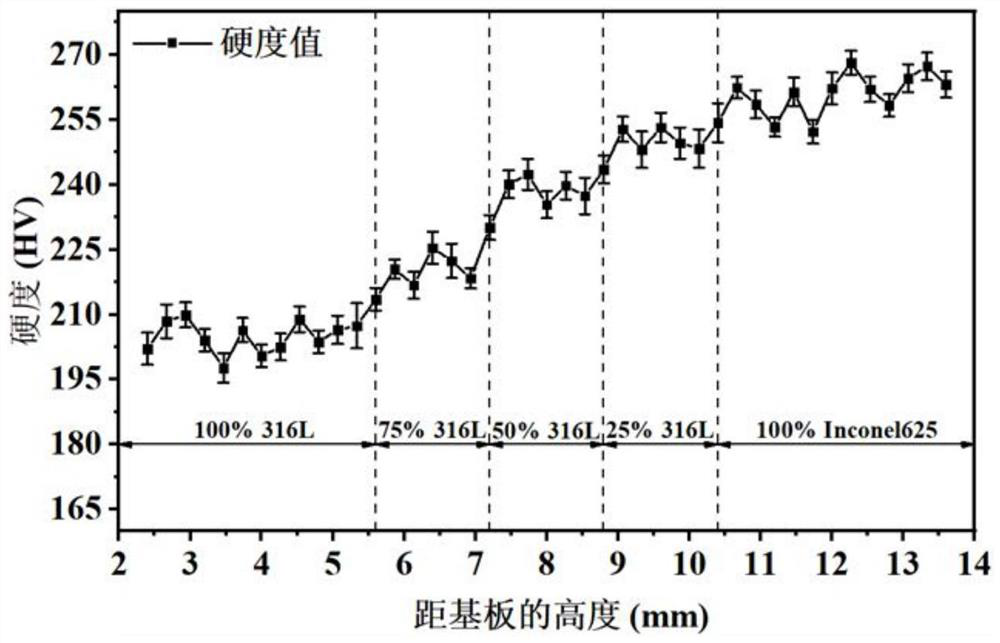

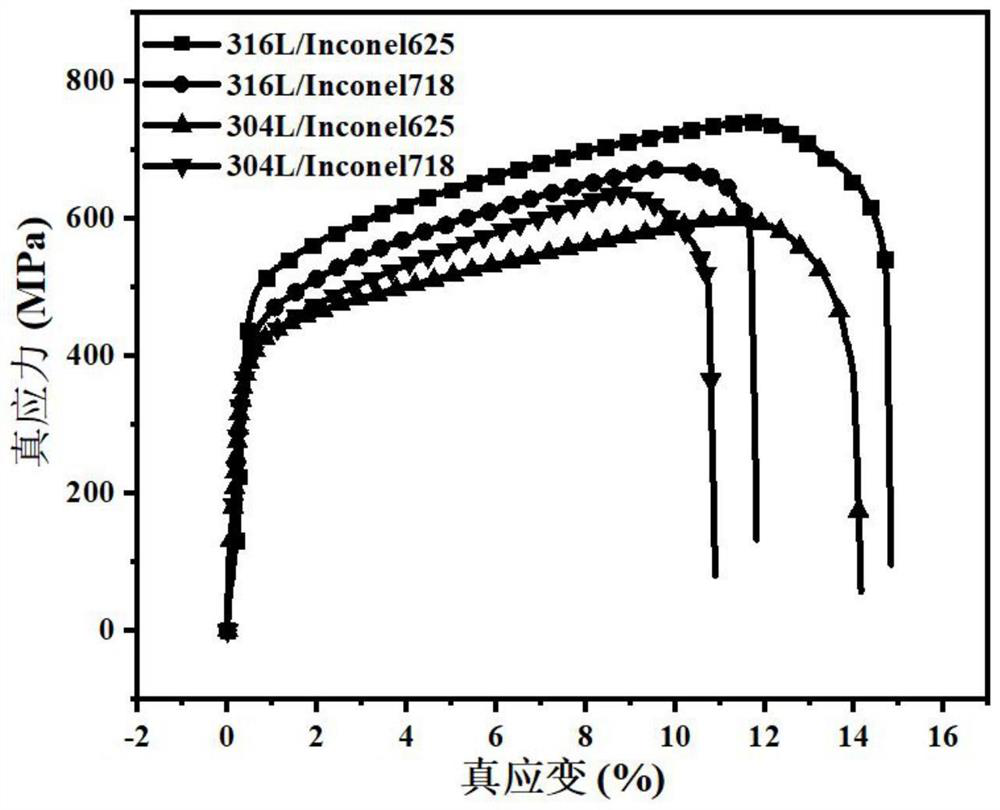

[0042] A nickel-based superalloy / stainless steel gradient composite material, the schematic diagram of which is shown in figure 1 , the specific preparation method comprises the following steps:

[0043] 1) The selected size is 150×150×10cm 3 The rolled 316L stainless steel alloy plate is used as the substrate, the surface of the substrate is first polished with sandpaper, and then the surface oil stains are cleaned with anhydrous ethanol;

[0044] 2) First fill the building cabin with high-purity argon gas (<1000ppm) to prevent oxidation of the sample during the printing process; then, weigh an appropriate amount of Inconel625 nickel-based superalloy powder and 316L stainless steel powder, of which Inconel625 nickel-based superalloy powder The average particle size of the 316L stainless steel powder is 93 μm, and the average particle size of the 316L stainless steel powder is 90 μm. The weighed Inconel625 nickel-based superalloy powder and 316L stainless steel powder are res...

Embodiment 2

[0054] A nickel-based superalloy / stainless steel gradient composite material, a specific preparation method comprising the following steps:

[0055] 1) The selected size is 150×150×10cm 3 The rolled 316L stainless steel alloy plate is used as the substrate to first polish the surface of the substrate with sandpaper, and then use anhydrous ethanol to clean the surface oil stains;

[0056] 2) First fill the building cabin with high-purity argon gas (<1000ppm) to prevent oxidation of the sample during the printing process; then, weigh an appropriate amount of Inconel718 nickel-based superalloy powder and 316L stainless steel powder, of which Inconel718 nickel-based superalloy powder The average particle size of the 316L stainless steel powder is 91 μm, and the average particle size of the 316L stainless steel powder is 90 μm. Put the weighed Inconel718 nickel-based superalloy powder and 316L stainless steel powder into the corresponding powder feeding barrels; adjust the laser po...

Embodiment 3

[0065] A nickel-based superalloy / stainless steel gradient composite material, a specific preparation method comprising the following steps:

[0066] 1) The selected size is 150×150×10cm 3 The rolled 304L stainless steel alloy plate is used as the substrate, the surface of the substrate is first polished with sandpaper, and then the surface oil stains are cleaned with anhydrous ethanol;

[0067] 2) First fill the building cabin with high-purity argon gas (<1000ppm) to prevent oxidation of the sample during the printing process; then, weigh an appropriate amount of Inconel625 nickel-based superalloy powder and 304L stainless steel powder, among which Inconel625 nickel-based superalloy powder The average particle size of the 304L stainless steel powder was 93 μm, and the average particle size of the 304L stainless steel powder was 88 μm. The weighed Inconel625 nickel-based superalloy powder and 304L stainless steel powder were respectively put into the corresponding powder feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com