Method for positioning transverse cracks of carbon fiber composite material by using chirp grating

A composite material and chirped grating technology, applied in the field of material science, can solve the problems of high cost, complex equipment, difficult online monitoring, etc., and achieve the effect of simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

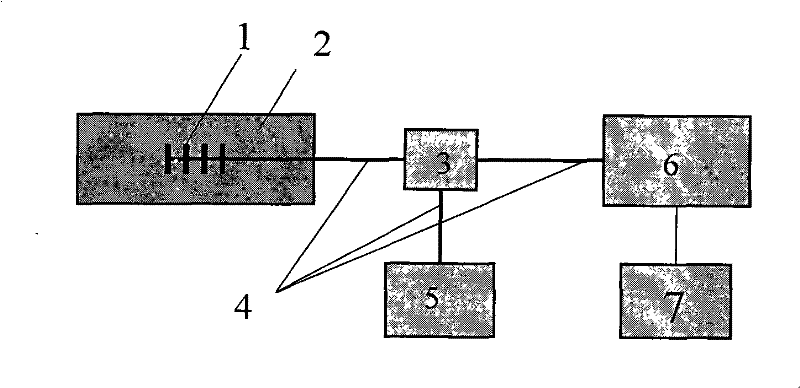

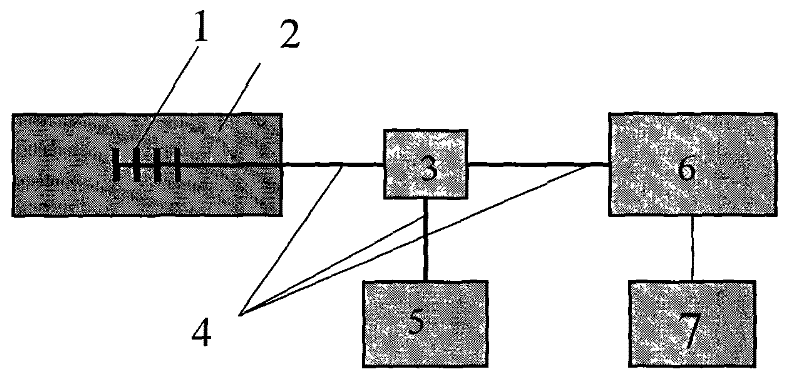

[0013] exist figure 1 Among them, symbol 1 represents chirped grating sensor; symbol 2 represents composite orthogonal laminate; symbol 3 represents coupler; symbol 4 represents optical fiber; symbol 5 represents broadband light source; symbol 6 represents optical fiber sensor analyzer; symbol 7 represents computer analysis system.

[0014] Such as figure 1 Shown: A method for locating transverse cracks in carbon fiber composites with chirped gratings, the steps are as follows:

[0015] (1) Make carbon fiber composite material orthogonal laminate 2, and its layering sequence is [0° 2 / 90° 4 / 0° 2 ], the chirped grating sensor 1 is embedded in the 0° layer of the carbon fiber composite orthogonal laminate 2, adjacent to the 90° layer.

[0016] (2) The chirped grating sensor 1 is connected to the coupler 3 through the optical fiber 4, and then the coupler 3 is connected to the broadband light source 5 through the optical fiber 4, and the coupler 3 is connected to the fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com