High-remanence low-coercivity permanent magnetic material and preparation method thereof

A low coercivity, permanent magnet material technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of high coercivity of permanent magnet materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

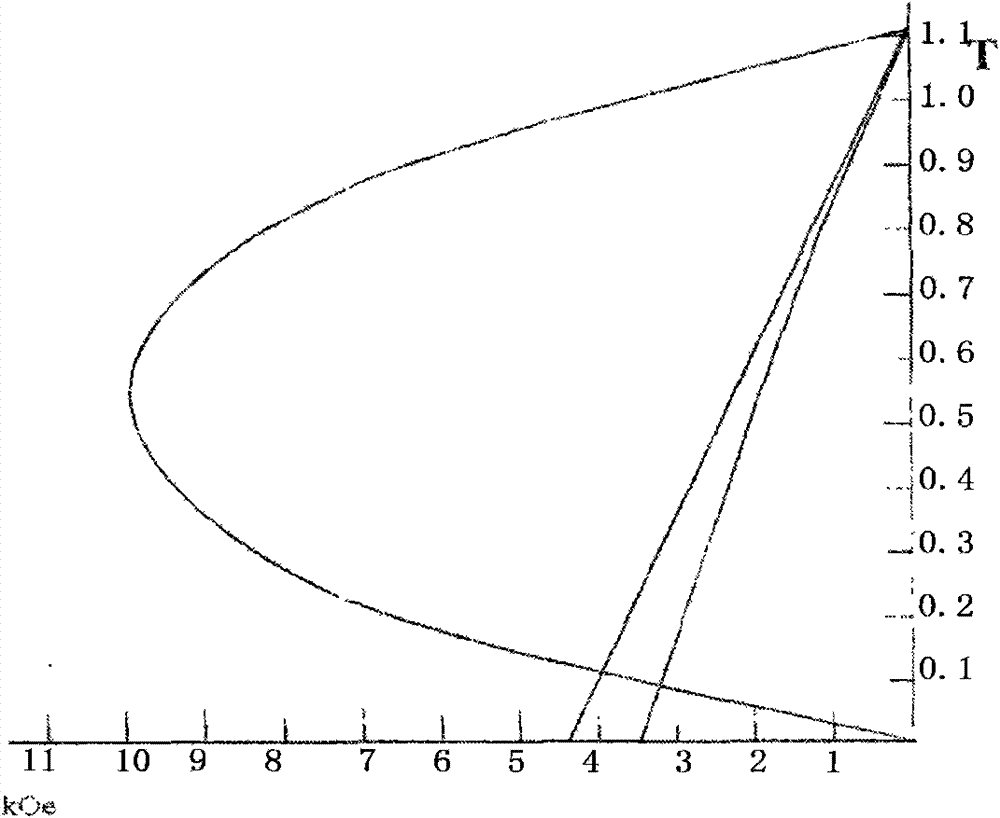

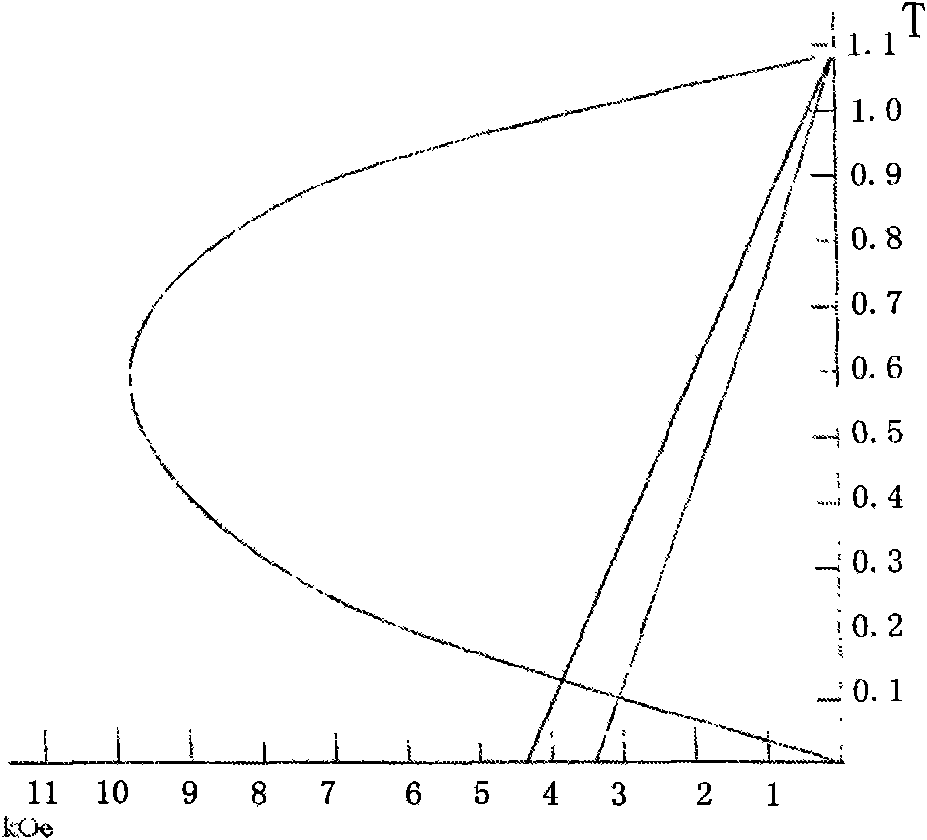

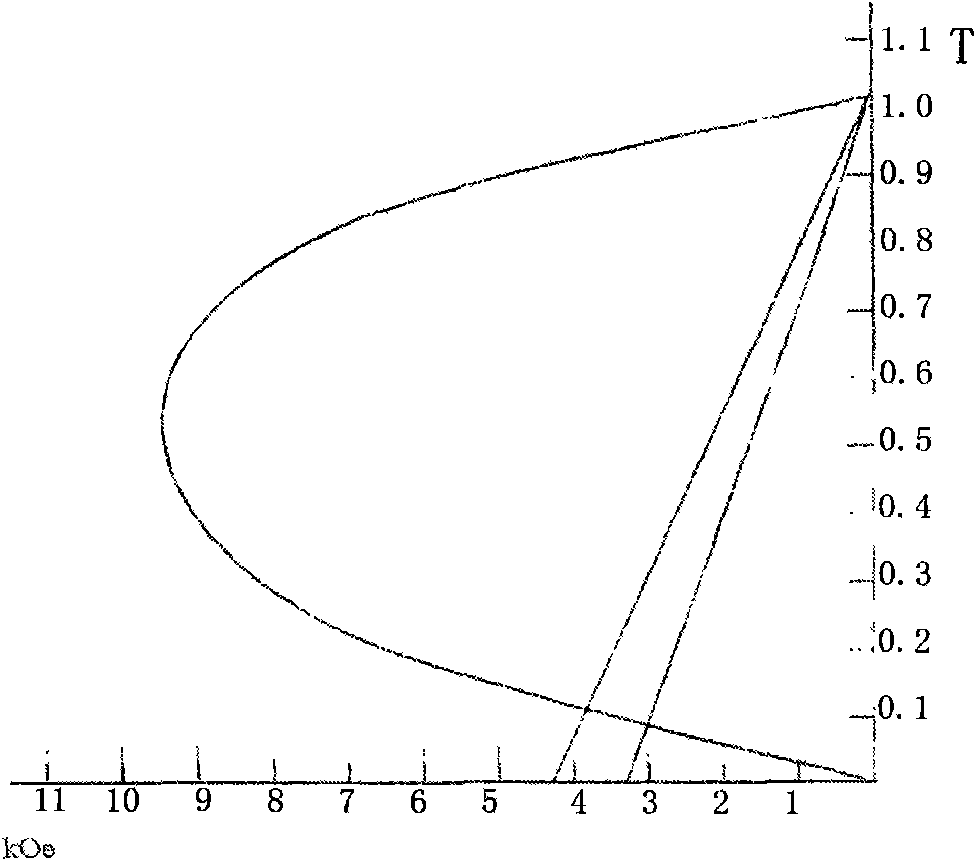

Image

Examples

Embodiment 1-3

[0020] Take pure Nd, pure Fe, B-Fe (wherein the atomic percentage of B is 19%), Cu, Al and Si according to the following proportions:

[0021] 1. 4.2at% Nd 73.4at% Fe 18.7at% B 0.8at% Cu 1.5at% Al 1.4at% Si;

[0022] 2. 4.2at% Nd 74at% Fe 18.7at% B 0.6at% Cu 1.3at% Al 1.2at% Si;

[0023] 3. 4.2at% Nd 74.6at% Fe 18.7at% B 0.4at% Cu 1.1at% Al 1.0at% Si;

[0024] The induction melting furnace is used for melting, and the melting vacuum is 5×10 -2 Pa, and filled with Ar gas to a vacuum of 0.06Mpa in the furnace as a protective gas to prevent oxidation of the alloy ingot. After smelting, it is poured on a pouring mold with cold water, and the pouring time is controlled at 2-3 minutes, wherein the embodiment 1 and 2 are 2.5 minutes, and the embodiment 3 is 3 minutes. After cooling for 1 hour, it will be released normally. At this time, the main phase structure in the alloy ingot is Nd 2 Fe 14 B phase, α-Fe phase and Fe 3 Phase B, due to the control of the addition of Cu, Al, S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com