Filled polymeric membranes, use and method of manufacturing

A technology for filling polymers and fillers, which can be used in separation methods, chemical instruments and methods, membranes, etc., and can solve problems such as selectivity decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

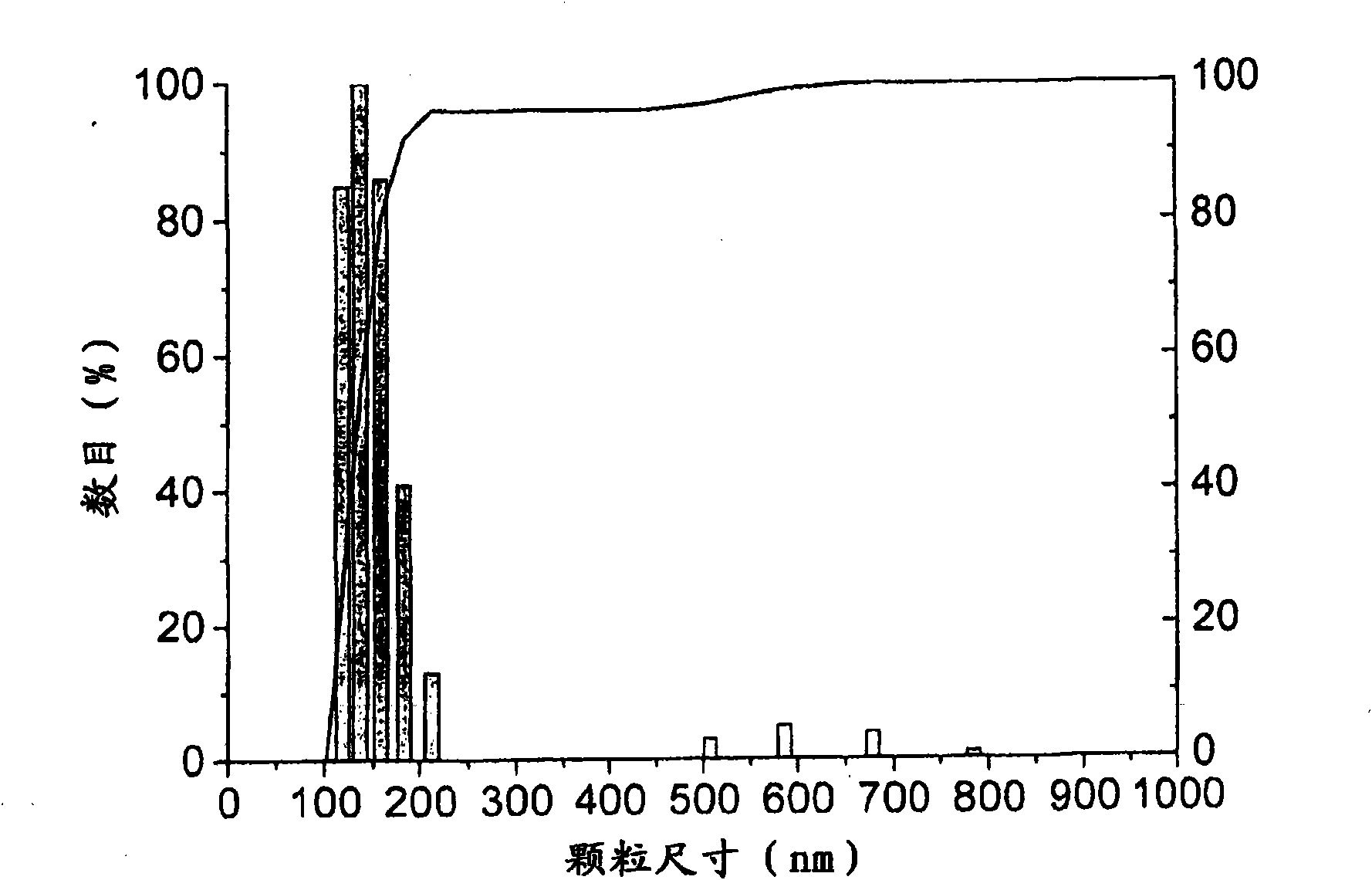

[0110] 1.002 grams of silica nanoparticles (TS-530) were added to 50 grams of toluene and magnetically stirred for 5 minutes. Aggregates of silica nanoparticles in suspension had an average aggregate size of 110 nm. Thereafter, 1 gram of PTMSP was added and the suspension was magnetically stirred for 4 days until the polymer was completely dissolved into the suspension. Next, the suspension was cast on a glass plate, and the solvent was allowed to evaporate under ambient conditions, leaving a 125 micron thick thin film (ie, membrane) of the filled polymer. After evaporation, the polymer film was removed from the glass plate by soaking in desalinated water. The nanoparticle filler constituted 50 wt% of the membrane.

[0111] The membrane was heated at 80°C for 2 hours and tested for pervaporation of ethanol / water mixtures. A feed of water mixture containing 10 wt% ethanol was circulated on one side of the membrane and a vacuum of 0.2 mbar was maintained on the other side of ...

Embodiment 2

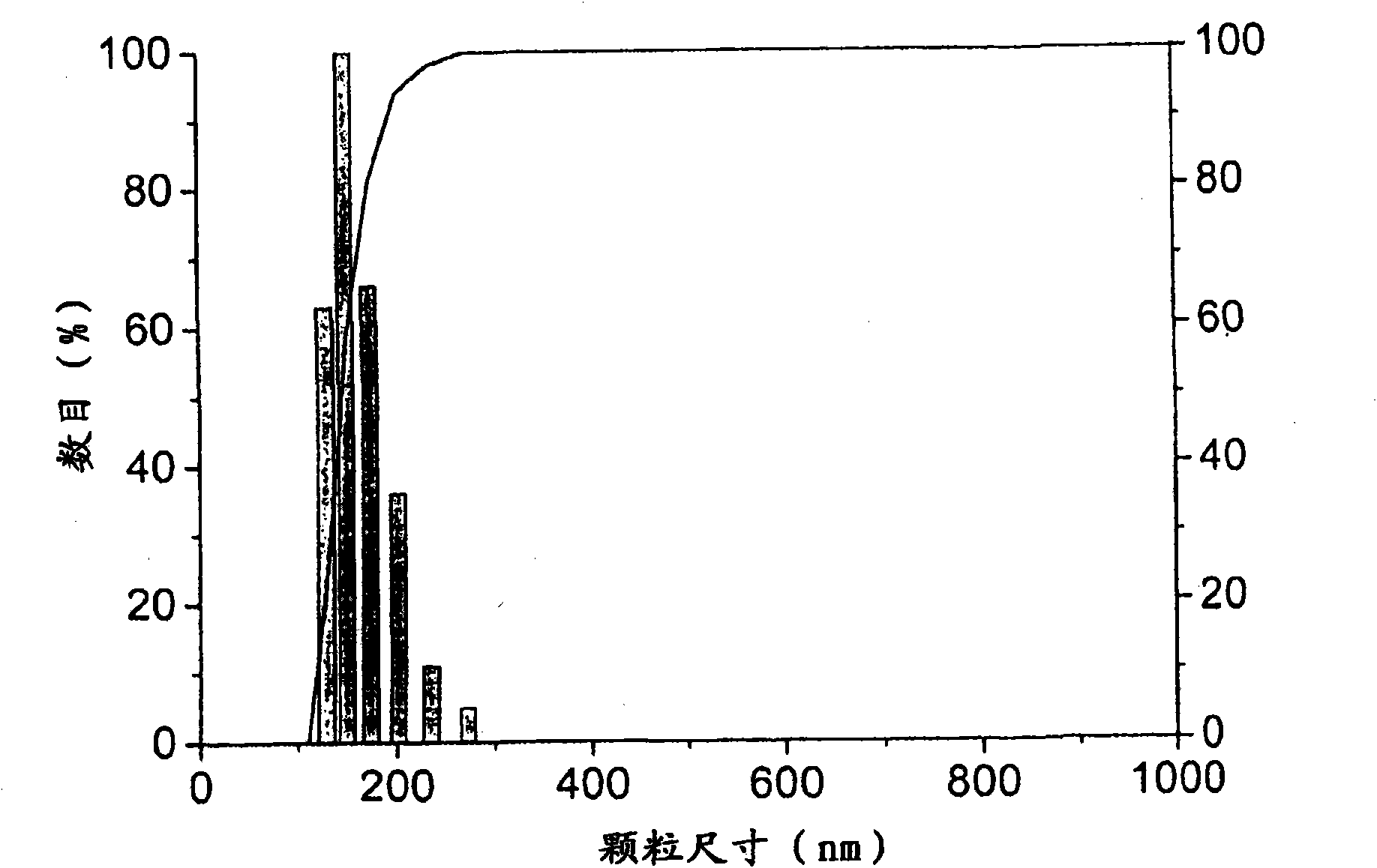

[0113] The PTMSP / silica / toluene suspension of example 1 was diluted to a dry matter content of 3% by weight and cast on a porous polyacrylonitrile (PAN) layer with a cast thickness of 1 mm. After solvent evaporation, a 30 micron film of filled polymer (ie membrane) was formed on the porous PAN layer. The weight fraction of nanoparticle filler in the film is 50 wt%.

[0114]The resulting membranes were heated at 80° C. for 2 hours in order to completely remove the solvent and test the pervaporation of ethanol / water mixtures. A water mixture containing 5 wt% ethanol was circulated on one side of the membrane and a vacuum of 0.2 mbar was maintained on the other side of the membrane. On the other side the permeate was collected as a 40 wt% ethanol / water mixture. The flux through the membrane is 1.25 kg / m 2 Hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com