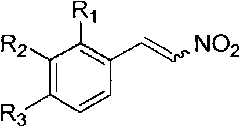

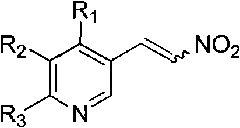

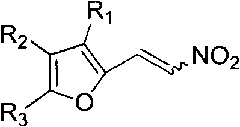

Method for synthesizing 4-aryl-4,5-dihydrofuran

A technology for dihydrofuran and derivatives, which is applied in the field of high-yield synthesis of 4-aryl-4, can solve the problems of low yield, poor substrate universality, complex synthesis process, etc., and achieve simple reaction process and low cost Low, easy-to-handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0040] Embodiment 1-3 mainly investigates the influence of temperature of reaction, reaction time

[0041]

Embodiment 1

[0043] With β-nitrostyrene (0.2mol) 29.8g, acetylacetone (0.4mol) 40.0g, K 2 CO 3 (0.12mol) 16.6g, DMSO (200ml), was added to a 500ml reaction flask. After stirring and reacting at 30°C for 8 hours, the conversion of the nitrostyrene raw material was complete. Dilute hydrochloric acid (1 mol / L) was added to pH = 6, extracted with ethyl acetate, washed with water and saturated brine in turn once. Dry over anhydrous sodium sulfate, evaporate ethyl acetate, and separate by flash column chromatography (petroleum ether: ethyl acetate = 8:1) to obtain the target product with a yield of 58%.

Embodiment 2

[0045] With β-nitrostyrene (0.2mol) 29.8g, acetyl lactone (0.4mol, 2eq) 40.0g, K 2 CO 3 (0.12mol, 0.6eq) 16.6g, DMSO (200ml), was added to a 500ml reaction flask, stirred and reacted at 80°C for 1 hour, and the conversion of the nitrostyrene raw material was complete. Dilute hydrochloric acid (1 mol / L) was added to pH = 6, extracted with ethyl acetate, washed with water and saturated brine in turn once. Dry over anhydrous sodium sulfate, evaporate ethyl acetate, separate by flash column chromatography (petroleum ether: ethyl acetate = 8: 1), yield 94%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com