Fermentation production technique of schizogenesis chytrid

A technology of Schizochytrium and fermentation tank, which is applied in the field of microbial fermentation production, and can solve the problems of high production cost and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Effects of Compound Nitrogen Source Medium on Biomass and DHA Content of Schizochytrium

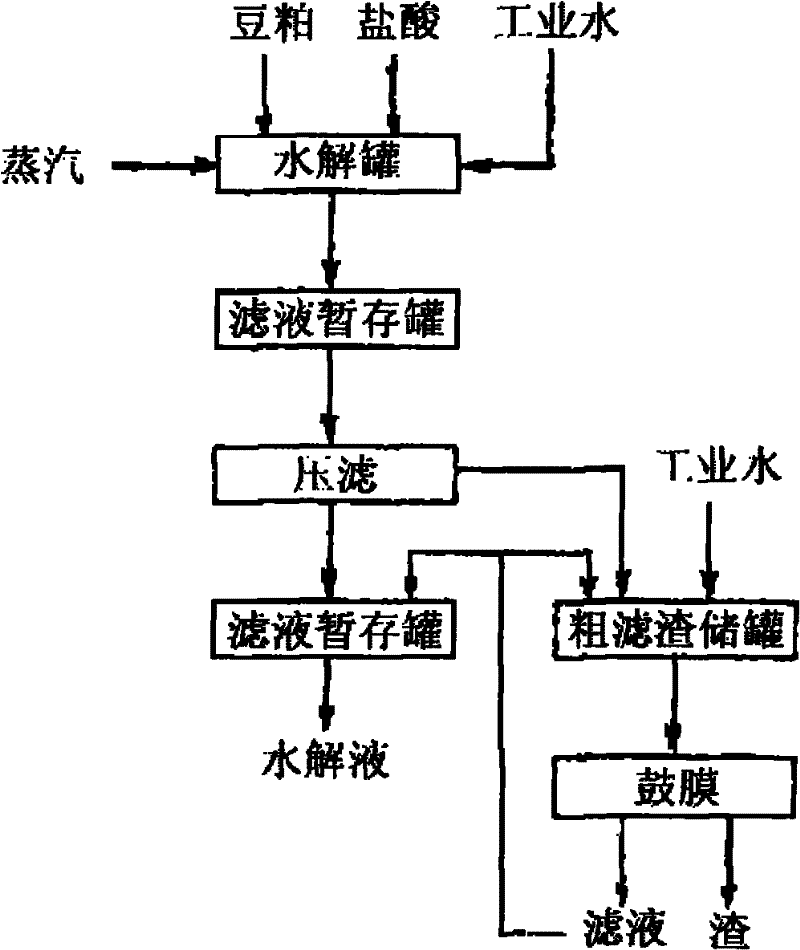

[0038] Preparation of soybean meal hydrolyzate (converted into soybean meal weight) with a concentration of 40g / L

[0039] a. Add 82mL of hydrochloric acid with a concentration of 1mol / L to 40g of soybean meal, and add 231mL of distilled water.

[0040] b. 121°C, high temperature hydrolysis for 30 minutes.

[0041] c. Add 1mol / L NaOH to adjust the pH to 7.0, centrifuge, and keep the supernatant.

[0042] d. Add distilled water to dilute the supernatant to 1 L, and the obtained solution is a soybean meal hydrolyzate with a concentration of 40 g / L (converted to the weight of soybean meal).

[0043] e. If other concentration of soybean meal hydrolyzate is needed, just adjust the dosage of soybean meal accordingly.

[0044] In a 250ml Erlenmeyer shaker flask, add 25ml natural seawater and 25ml distilled water respectively, add carbon source (glucose) and nitrogen source (soybean mea...

Embodiment 2

[0049] Effects of Different Soybean Meal Hydrolysis Processes on the Biomass and DHA Content of Schizochytrium

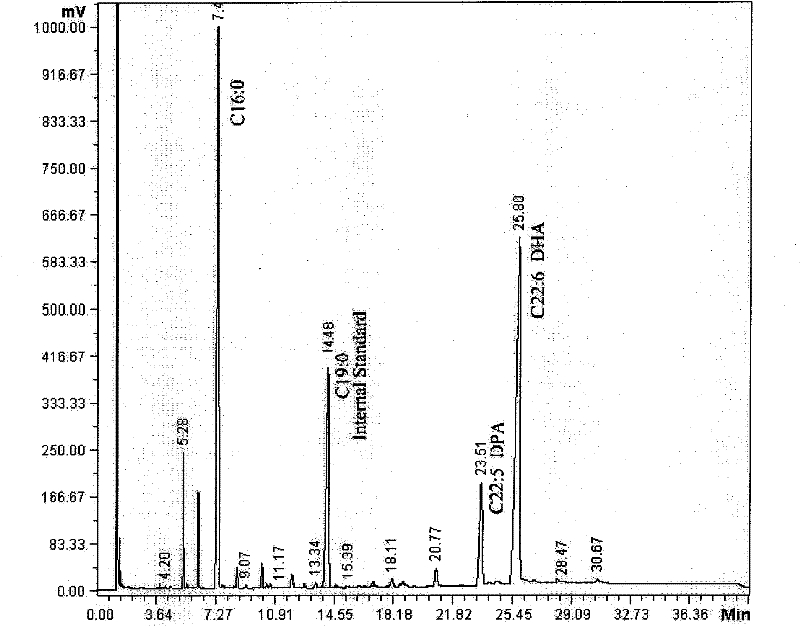

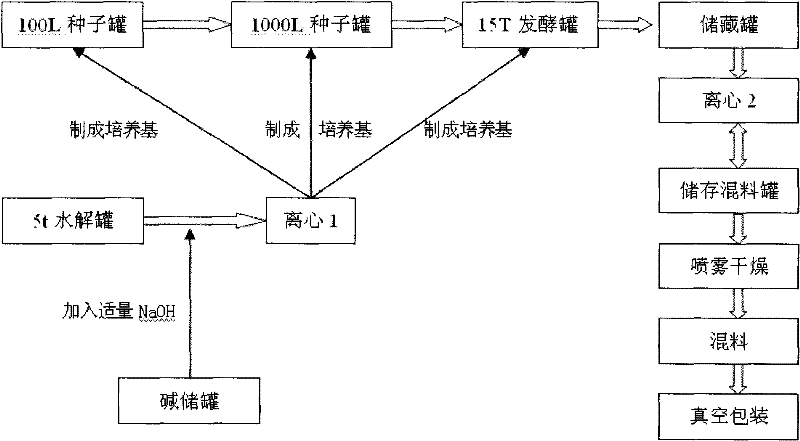

[0050] After the soybean meal hydrolyzate is prepared in the following way, add 600L medium to a 1000L fermenter, adjust the pH value to 6.0, and add vitamins B1, B12, H. After sterilization, insert the bacteria seed solution and cultivate at 25°C 4 days. Collect the cells by centrifugation and measure their dry weight; 3 -Methyl esterification by methanol method, the percentage content of DHA in the bacteria is determined by gas chromatography. The results are shown in Table 2.

[0051] Hydrolysis scheme

[0052] A Add soybean meal powder and appropriate amount of water into the enamel reaction kettle, add 30% concentrated hydrochloric acid to adjust the pH of the solution to 1.3. Steam is heated to 110°C and kept for 30 minutes. After cooling, the pH is adjusted to 6.0. The residue is separated from the solution, and the obtained supernatant is used as the cul...

Embodiment 3

[0061] Effects of Different Hydrolysis Conditions on the Biomass and DHA Content of Schizochytrium

[0062] After determining the hydrolysis scheme, the hydrolysis time (min), hydrolysis temperature (°C), and acid concentration (M) were used for orthogonal experiment optimization; the experimental gradient was hydrolysis time 15min, 20min, 25min, hydrolysis temperature 100°C, 110°C, 120°C, hydrochloric acid concentration 0.25mol / L, 0.4mol / L, 1.0mol / L. Add 600L medium to a 1000L fermenter, adjust the pH value to 6.0, and add vitamins. After sterilization, insert the bacterial seed solution and cultivate at 25°C for 4 days. Collect the cells by centrifugation and measure their dry weight; 3 -Methyl esterification by methanol method, the percentage content of DHA in the bacteria is determined by gas chromatography. The results are shown in Table 3.

[0063] Table 3 Orthogonal experiment table for optimization of hydrolysis conditions

[0064] experiment

[0065] Usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com