Method for manufacturing composite fiber F-P sensor based on self-focusing effect

A technology of a composite structure and a manufacturing method, which is applied in the transmission of sensing components, instruments, optics and other directions using optical devices, can solve the problems of difficulty in low-cost, mass production, high adjustment accuracy requirements, and high processing system costs. Reduce optical transmission loss, simple production steps, and improve the effect of reflected spectral fringe contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

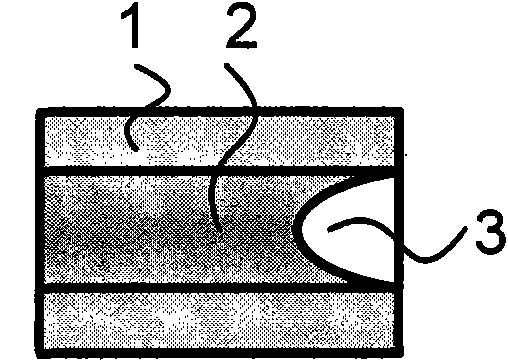

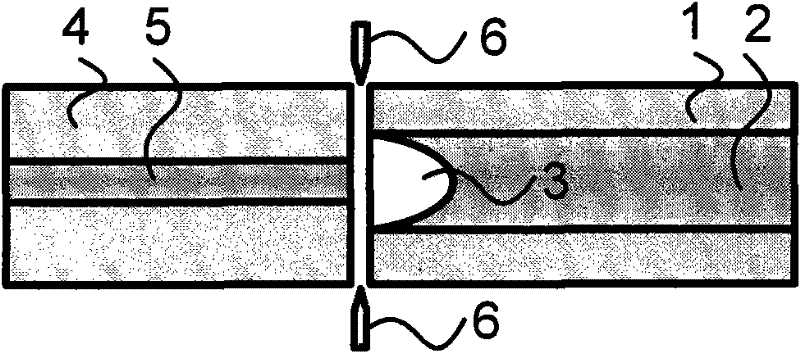

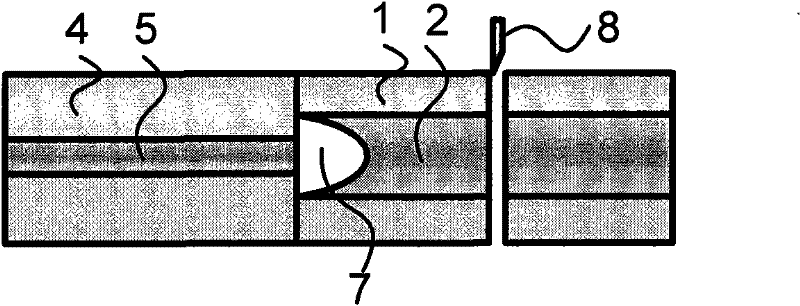

[0027] Adopt spectrum analyzer 9, 3dB coupler 10 and fiber optic method Perot composite structure sensor 11 to constitute the refractive index and temperature of sensing system measurement solution 12, as Image 6 shown. At the same time, the temperature and refractive index are calibrated by the thermometer 13 and the Abbe refractometer. The reflection spectrum of the fiber-optic F-P composite sensor 11 is recorded by a spectrum analyzer 9 . During the fabrication process of the fiber-optic F-P composite structure sensor, the reflection spectra of the single-mode fiber end face, the air cavity and the F-P composite structure sensor are as follows: Figure 7 shown. The fringe contrast ratio of the reflection spectrum of the optical fiber F-P composite structure sensor can reach more than 32dB.

[0028] Refractive index and temperature are measured by changes in fringe contrast and wavelength shift, respectively. The temperature measurement results of the fiber-optic F-P co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com