Preparation method of PtRu/C binary alloy nano catalyst

A nano-catalyst and binary alloy technology, which is applied in the field of materials, can solve the problems of wide catalyst metal particle size range, and achieve the effects of narrow particle size range, advanced oxidation potential, and anti-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 30.0mg of activated carbon in 30ml of aqueous solution, raise the temperature to 40°C, stir magnetically (stirring rate 500r / min), and form a carbon slurry after 30min, slowly and sequentially add 5mL of 0.5mM H 2 PtCl 6 , 5mL 0.5mM RuCl 3 , (metal molar ratio Pt:Ru=1:1), add 14.7mg trisodium citrate as metal protective agent (trisodium citrate molarity: total metal molarity=1:1), ultrasonically stir for 30min, use 0.1 M NaOH to adjust the pH of the solution to 8, at 40°C, slowly add 10mL 0.1M NaBH 4 As a reducing agent, react for 3 hours, vacuum filter, wash with water until there is no chloride ion in the solution, and vacuum dry at 70°C for 12 hours.

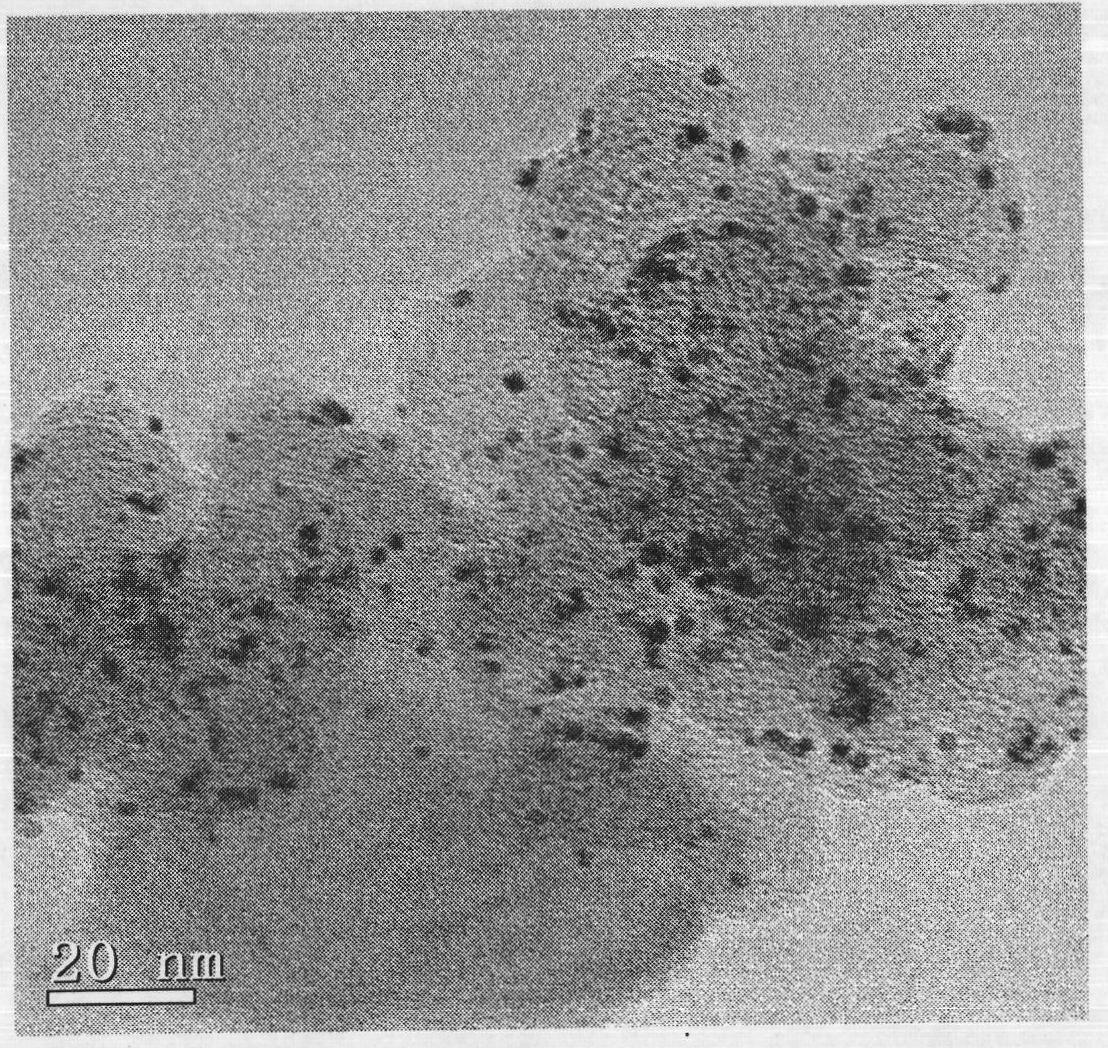

[0026] To the PtRu alloy nanometer catalyst of the present invention's gained, measure the PtRu alloy nano particle diameter by transmission electron microscope, as figure 1 shown.

[0027] from figure 1 It can be seen that the PtRu alloy nanoparticles are quite small, with a particle size of about 4 nm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com