Preparation method and application of composite nano nickel catalyst

A nano-nickel and composite technology, which is applied in the field of preparing composite nano-nickel catalysts, can solve the problems of low price, environmental pollution, waste alkali water pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

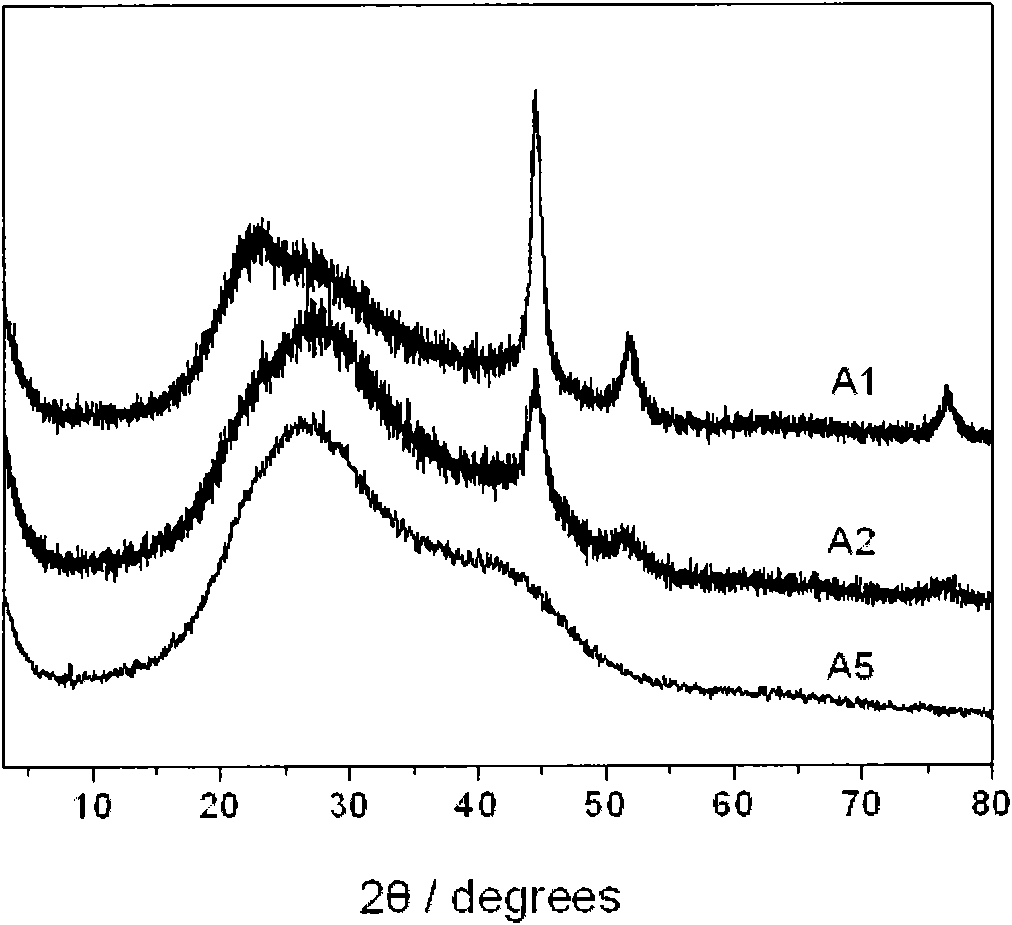

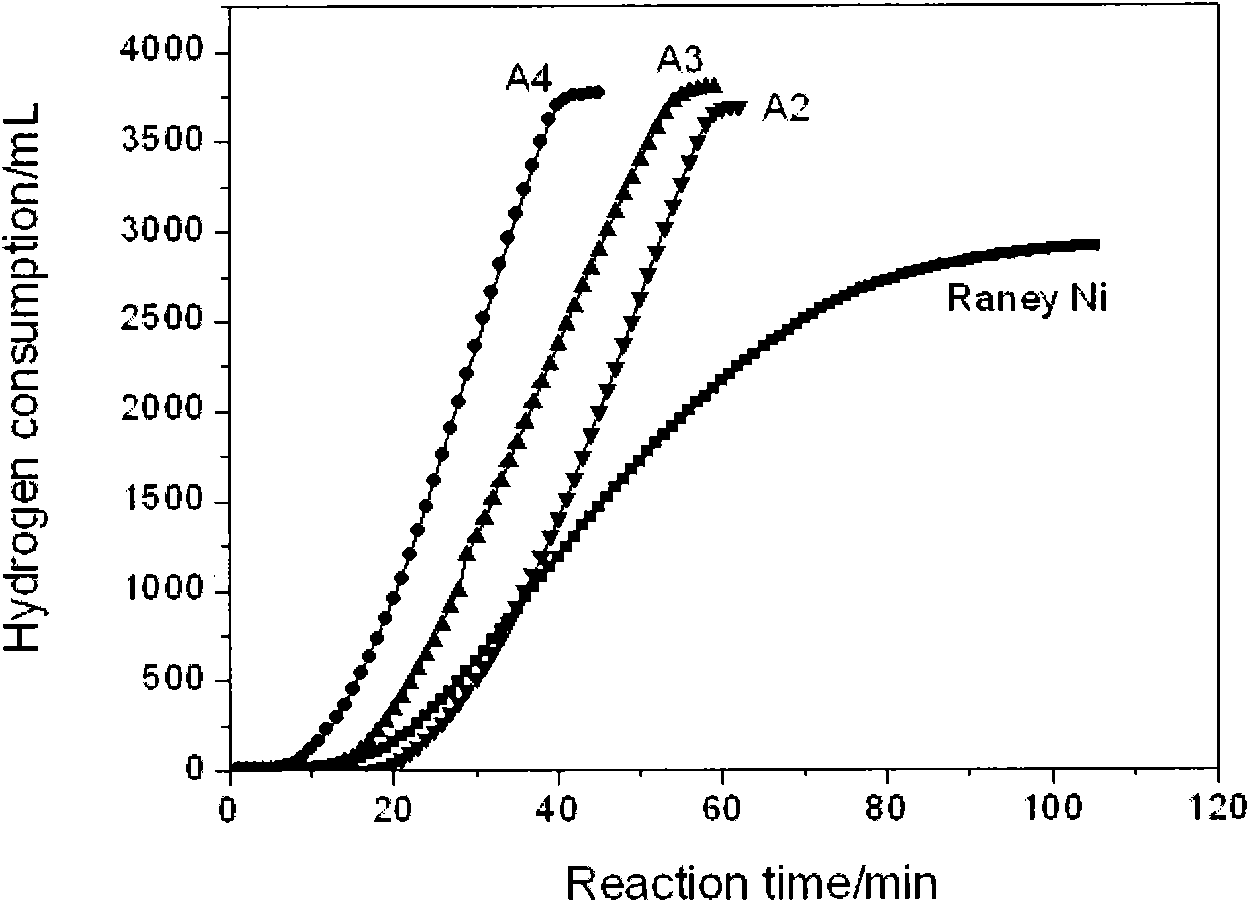

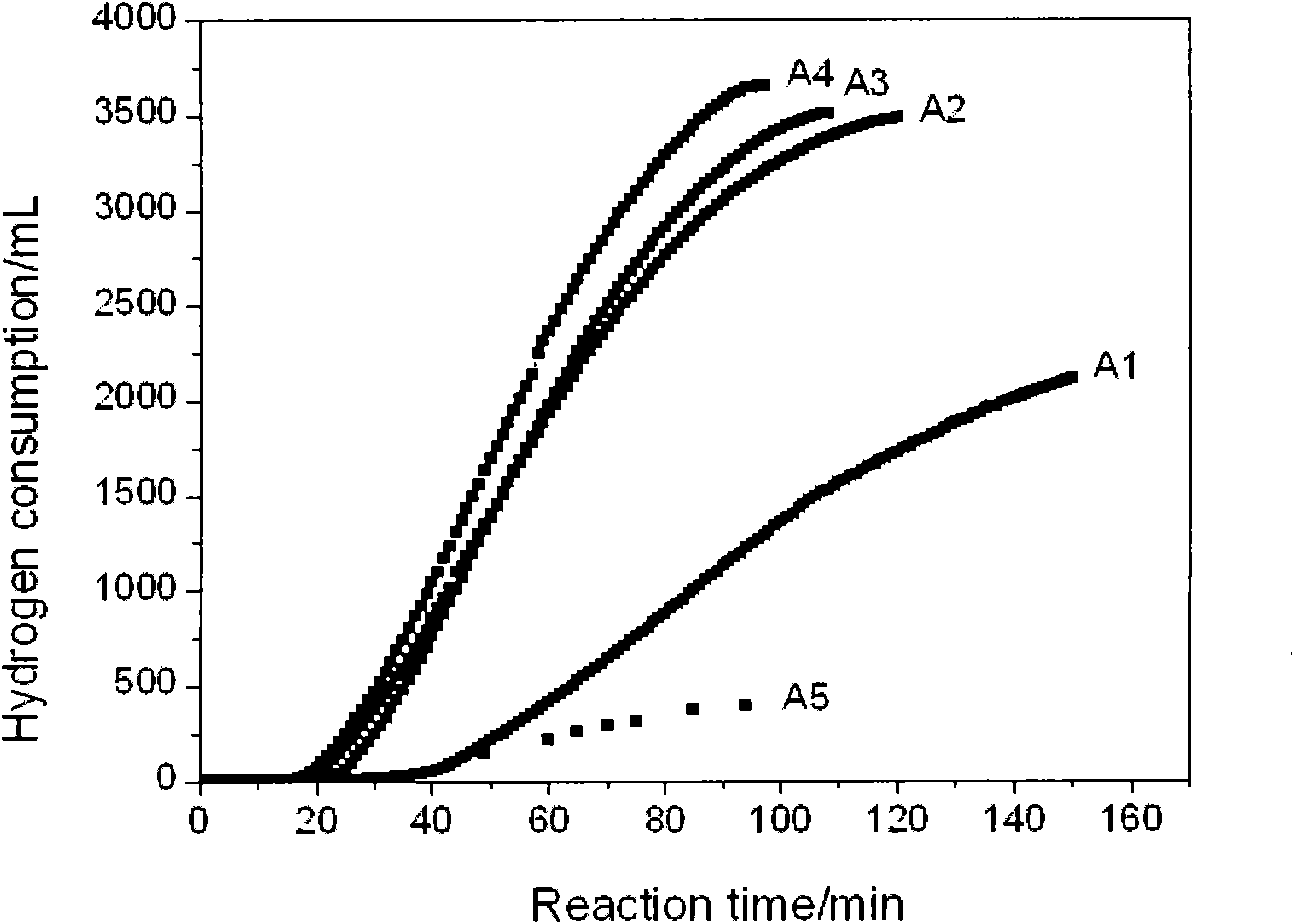

[0019] These examples illustrate that composite nano-nickel catalysts with different compositions are prepared by adjusting the ratio of amorphous and crystalline Ni with silica sol as a carrier.

[0020] The first is the preparation of silica sol supported amorphous Ni. Prepare a certain concentration of KBH 4 The solution has a concentration of 0.1 to 2.0 mol / L, and is uniformly mixed with a certain amount of silica sol. Then prepare a certain concentration of nickel salt solution, the concentration is 0.02 ~ 2.83mol / L, nickel salt and KBH 4 The molar ratio is 1:2. Under a certain protective gas, drop the nickel salt solution into the above mixed solution at a certain speed (1-12mL / min), control the reaction temperature at 0-30°C, and react until no gas is generated. The product is amorphous Ni supported by silica sol, and it is used as the precursor of reducing crystalline nano-nickel. Then, prepare a certain concentration of nano-nickel plating solution, its specific c...

Embodiment 2

[0022] These examples illustrate the process of using silica sols with different particle sizes as carriers to prepare composite nano-nickel catalysts.

[0023] Alkaline silica sols (20nm, 60nm, 80nm, 110nm, 130nm) of different particle sizes were used as carriers respectively, and the composite nano-nickel catalyst supported by silica sol was prepared according to the method in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com