Sodium silicate waste sand rotary vibration grinding wet-type regenerator

A recycling machine and water glass technology, applied in the cleaning/processing machinery of casting mold materials, casting molding equipment, metal processing equipment, etc., can solve the problems of large water consumption and achieve the effect of zero sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

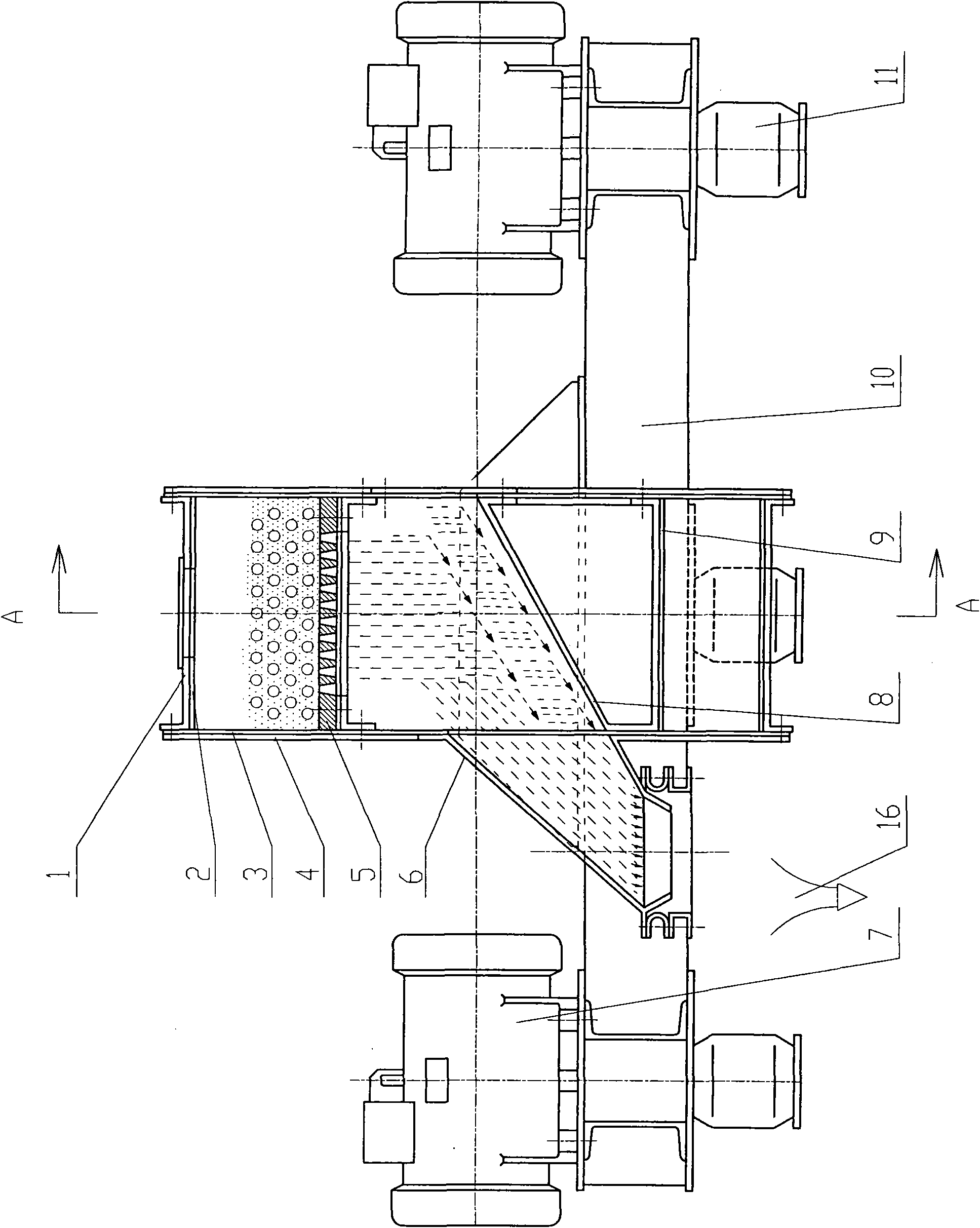

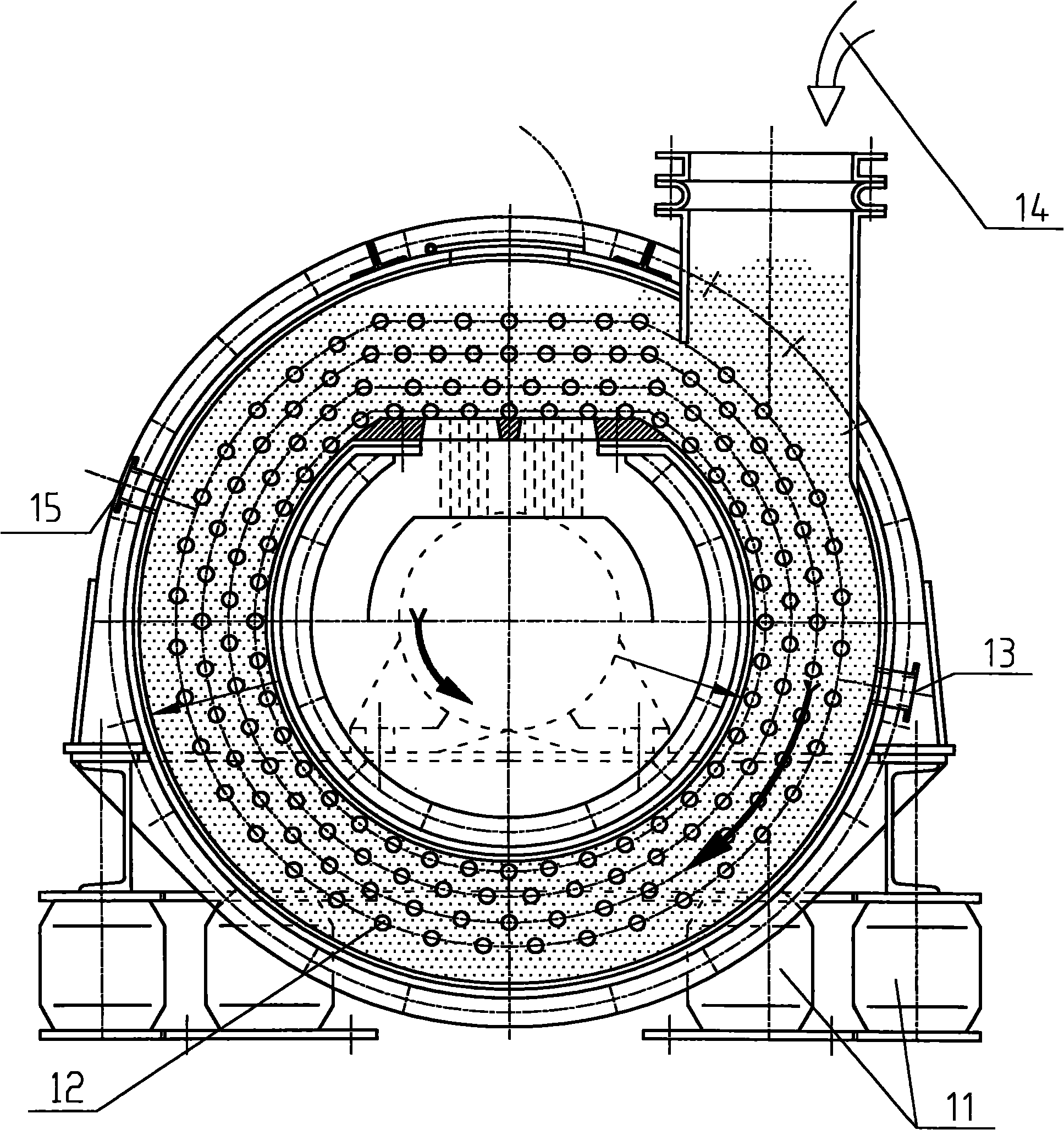

[0013] see Figure 1~2 , figure 1 It is a schematic diagram of the overall structure of the water glass used sand rotary vibration grinding wet recycling machine of the present invention. figure 2 for figure 1 A-A cut-away diagram. Depend on figure 1 and figure 2 It can be seen that the rotary vibration grinding wet-type regenerator of sodium silicate old sand of the present invention comprises a steel spiral rubber composite spring 11, a frame 10, an outer cylinder 1, an inner cylinder 8, cylinder side plates 4, ceramic grinding balls 12 and Vibration motor 7, said steel helical rubber composite spring 11 has six (also can be more than six), and six steel helical rubber composite springs 11 are divided into three groups, each group has two, wherein one group is symmetrical Arranged in the middle, the other two groups are symmetrically arranged on both sides of the middle group of steel helical rubber composite springs 11, such as image 3 shown. The outer edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com