Method for preparing lead zirconate titanate 95/5 porous ceramic from tetra-n-butyl titanate

A technology of tetra-n-butyl titanate and lead zirconate titanate is applied in the field of preparation of porous ceramics, which can solve problems such as poor pore size distribution uniformity and achieve the effect of uniform pore size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

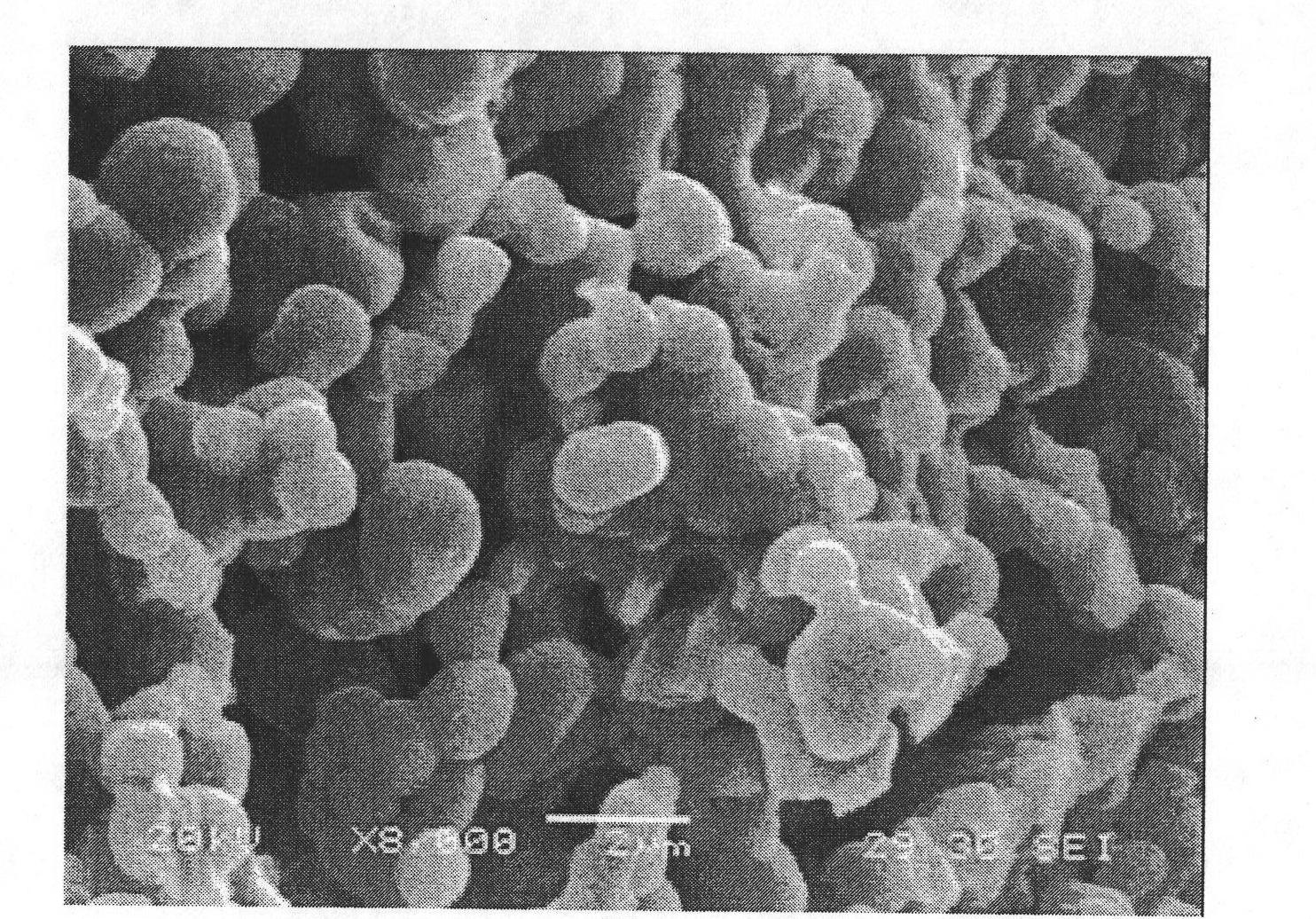

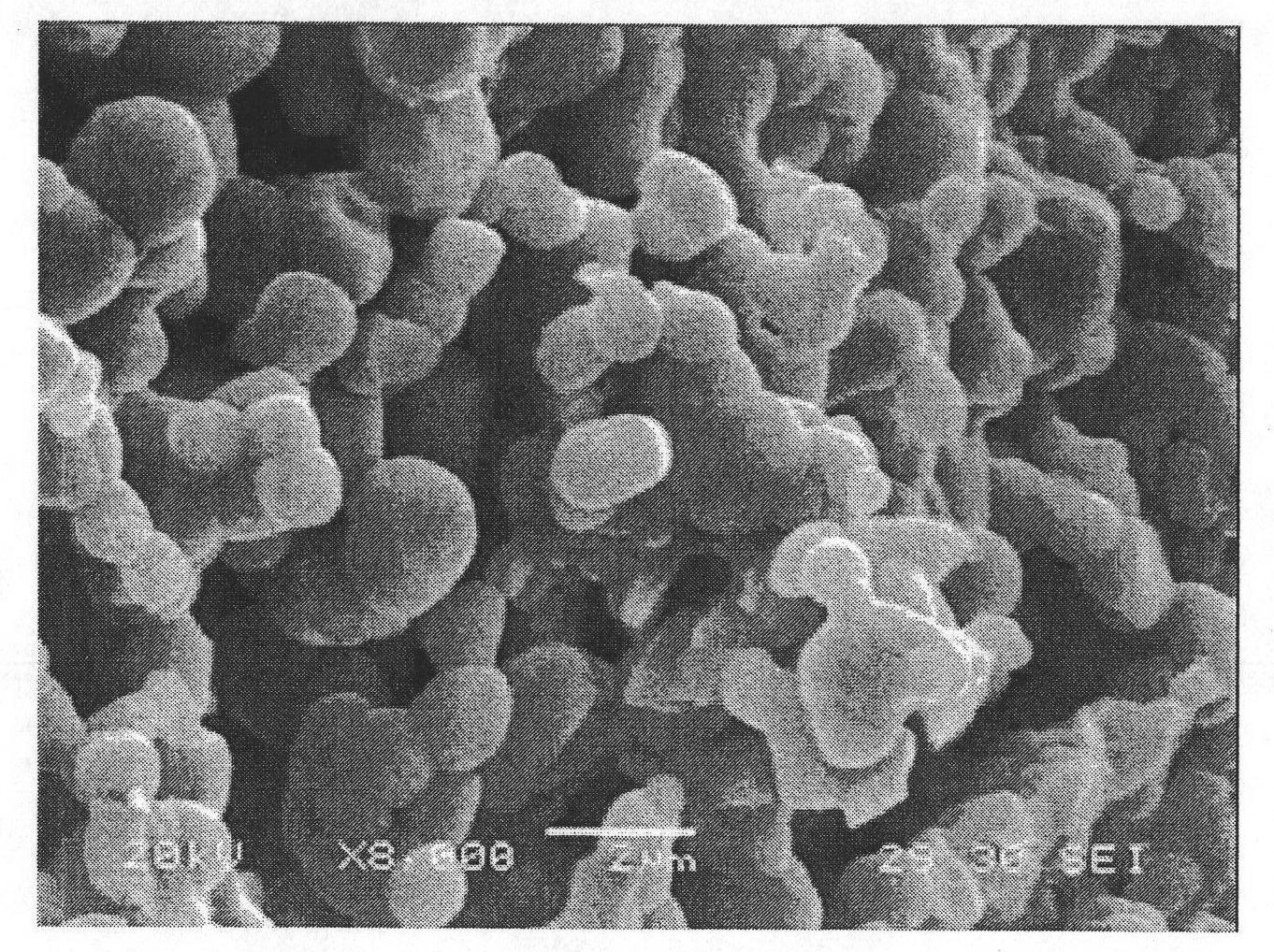

Image

Examples

Embodiment 1

[0014] Example 1, in the first step, the molar ratio of ethylene glycol: citric acid: lead nitrate: zirconyl nitrate: tetra-n-butyl titanate is 800: 200: 20: 19: 1, and the tetra-n-butyl titanate Add the ester to a container containing ethylene glycol and stir, add citric acid, and stir at 30°C until completely dissolved;

[0015] In the second step, heat up to 70°C, stir and react for 3 hours, then add lead nitrate, stir and dissolve at 70°C, continue stirring for 3 hours, then add zirconium oxynitrate, stir and dissolve at 70°C, and continue stirring for 4 hours ;

[0016] The third step is to raise the temperature to 150°C and keep it warm for 3 hours to promote the completion of the esterification reaction and obtain a gel;

[0017] The fourth step is to calcinate the obtained gel in a static atmosphere at 500°C for 2 hours to obtain lead zirconate titanate 95 / 5 powder;

[0018] In the fifth step, the obtained lead zirconate titanate 95 / 5 powder is molded by cold isostat...

Embodiment 2

[0020] Example 2, in the first step, the molar ratio of ethylene glycol: citric acid: lead nitrate: zirconyl nitrate: tetra-n-butyl titanate is 800: 200: 20: 19: 1, and the tetra-n-butyl titanate Add the ester to a container containing ethylene glycol and stir, add citric acid, and stir at 35°C until completely dissolved;

[0021] In the second step, heat up to 80°C, stir and react for 2 hours, then add lead nitrate, stir to dissolve at 80°C, continue to stir for 2 hours, then add zirconium oxynitrate, stir to dissolve at 80°C, and continue to stir and react for 3.5 hours ;

[0022] The third step is to raise the temperature to 140°C and keep it warm for 2 hours to promote the completion of the esterification reaction and obtain a gel;

[0023] The fourth step is to calcinate the obtained gel in a static atmosphere at 300°C for 6 hours to obtain lead zirconate titanate 95 / 5 powder;

[0024] In the fifth step, the obtained lead zirconate titanate 95 / 5 powder is molded by cold...

Embodiment 3

[0025] Example 3, in the first step, the molar ratio of ethylene glycol: citric acid: lead nitrate: zirconyl nitrate: tetra-n-butyl titanate is 800: 200: 20: 19: 1, and the tetra-n-butyl titanate Add the ester to a container containing ethylene glycol and stir, add citric acid, and stir at 40°C until completely dissolved;

[0026] In the second step, heat up to 85°C, stir and react for 1.5 hours, then add lead nitrate, stir and dissolve at 85°C, continue stirring for 1.5 hours, then add zirconium oxynitrate, stir and dissolve at 85°C, and continue to stir and react for 3 hours ;

[0027] The third step is to raise the temperature to 135°C and keep it warm for 1.5 hours to promote the completion of the esterification reaction and obtain a gel;

[0028] The fourth step is to calcinate the obtained gel in a static atmosphere at 700°C for 4 hours to obtain lead zirconate titanate 95 / 5 powder;

[0029] In the fifth step, the obtained lead zirconate titanate 95 / 5 powder is molded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com