Separation and detection method of irradiation product DBP (Double-Base Propellant) and/or MBP (Myelin Basic Protein) in TBP (Ttri-Butyl phosphate)-kerosene-HNO3 system

A technology for the separation of -HNO3, applied in the field of irradiated product dibutyl phosphate, which can solve the problems of low sensitivity, unsuitable for control analysis, long operating procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

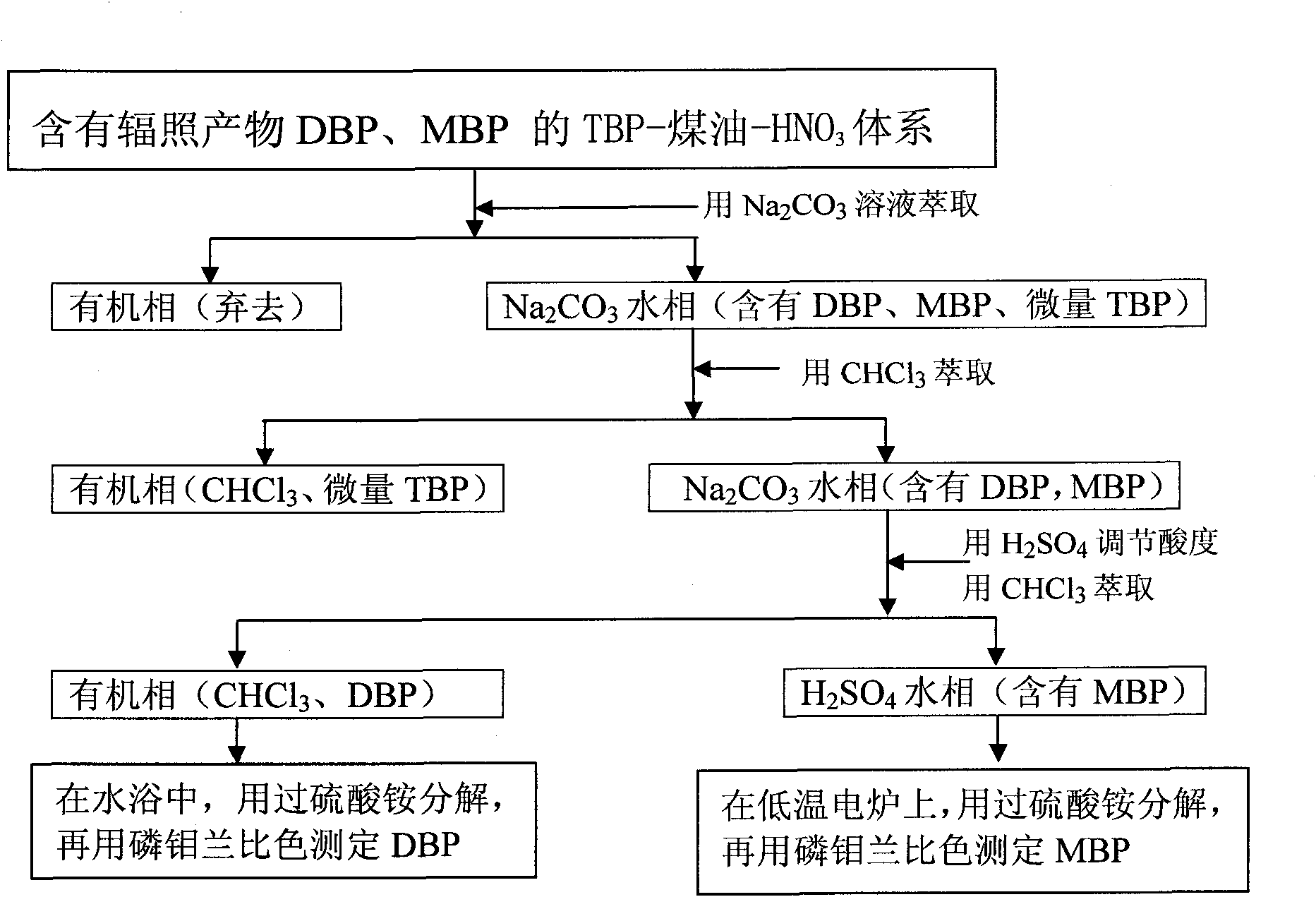

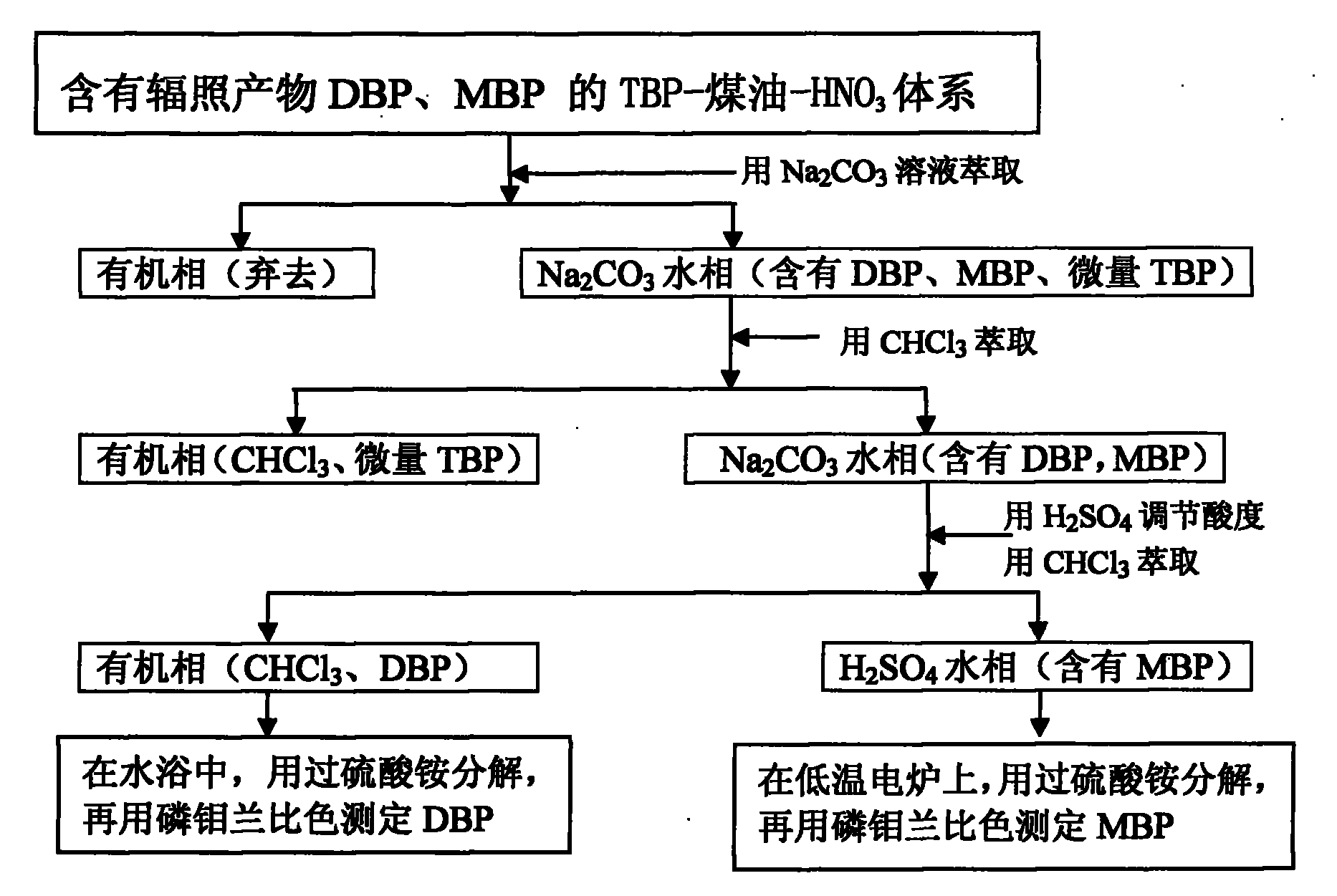

[0042] A TBP-kerosene-HNO 3 The separation method of the radiation product DBP and MBP in the system mainly comprises the following steps (such as figure 1 shown):

[0043] 1. Take TBP-kerosene-HNO 3 Put 9-11ml of lean organic phase samples in the uranium extraction process under the system into a 60ml separatory funnel, add 3-8% Na 2 CO 3 The solution is 9-11ml, extracted for 2-10 minutes, standing for stratification, the upper layer is the organic phase containing TBP-kerosene-HNO3 system, and the lower layer is Na containing DBP, MBP and trace TBP 2 CO 3 water box;

[0044] Two, put the Na layered in the first step 2 CO 3 The aqueous phase was put into another 60ml separatory funnel, and the 3 Wash once, the ratio is 0.8~1:0.8~1, that is, Na 2 CO 3 Aqueous phase and CHCl 3 The volume ratio is 0.8~1:0.8~1, shaking for 2~10 minutes, standing for stratification, standing for the CHCl in the stratification 3 The organic phase contains a small amount of TBP, and the ...

Embodiment 2

[0046] A TBP-kerosene-HNO 3 The separation method of the radiation product DBP or MBP in the system, after the above-mentioned two steps of embodiment 1, also includes the following steps:

[0047] Three, get the clarification Na in the second step of embodiment 1 static stratification 2 CO 3 Water phase 4~6ml, add 4~6mol / L sulfuric acid dropwise to near neutrality, pH value is equal to 6.5~7.5, that is, PH=6.5~7.5, then add 4~6ml 4.5~5.5mol / L sulfuric acid solution, at this time the solution The acidity is 3~4mol / L, after shaking gently, add 9~11ml of CHCl 3 Extract for 1 to 3 minutes, stand still for more than 15 minutes; let the CHCl in the stratified 3 The organic phase contains DBP; the H in the standing stratification 2 SO 4 The aqueous phase contains MBP.

Embodiment 3

[0049] A TBP-kerosene-HNO 3 The detection method of the radiation product DBP in the system, after the above-mentioned three steps of embodiment 2, also includes the following steps:

[0050] 4. Add 18-22ml of distilled water to a 100ml beaker, and take the CHCl extracted in the third step of Example 2 above 3 Put 4-6ml of the organic phase in the beaker, add 0.4-0.6g of ammonium superphosphate, and after it dissolves, put it in a boiling water bath and heat until the organic phase disappears, then move to a low-temperature electric furnace, continue boiling for 3-6 minutes, and heat Rinse the wall of the cup with water. After cooling down slightly, add 0.4-0.6g of sodium sulfite. After dissolving, heat to boiling. Take off the beaker. At this time, the organic phosphorus of DBP in the beaker is converted into inorganic phosphorus. Use the phosphomolybdenum blue colorimetric method Determination of DBP content.

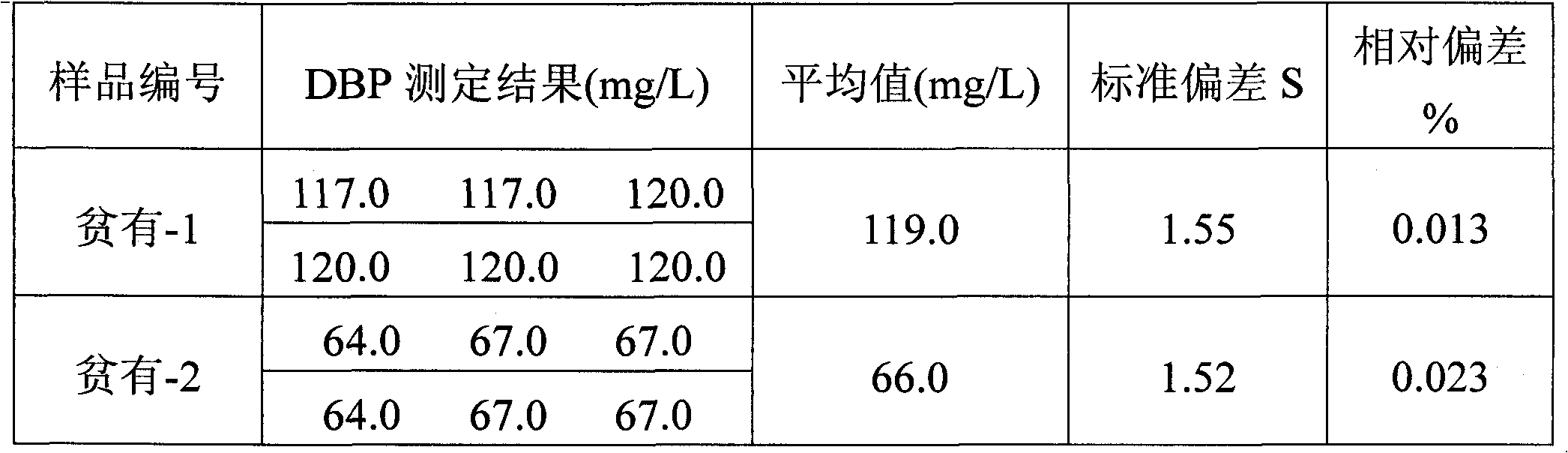

[0051] Experimental data 1

[0052] Take two TBP-kerosene-HNO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com