Method for grafting polyvinylpyrrolidone onto surface of graphene

A polyvinylpyrrolidone and graphene surface technology, applied in the field of preparation of nanomaterials technology, can solve problems such as low yield of monolayer graphene, and achieve the effect of a rapid preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

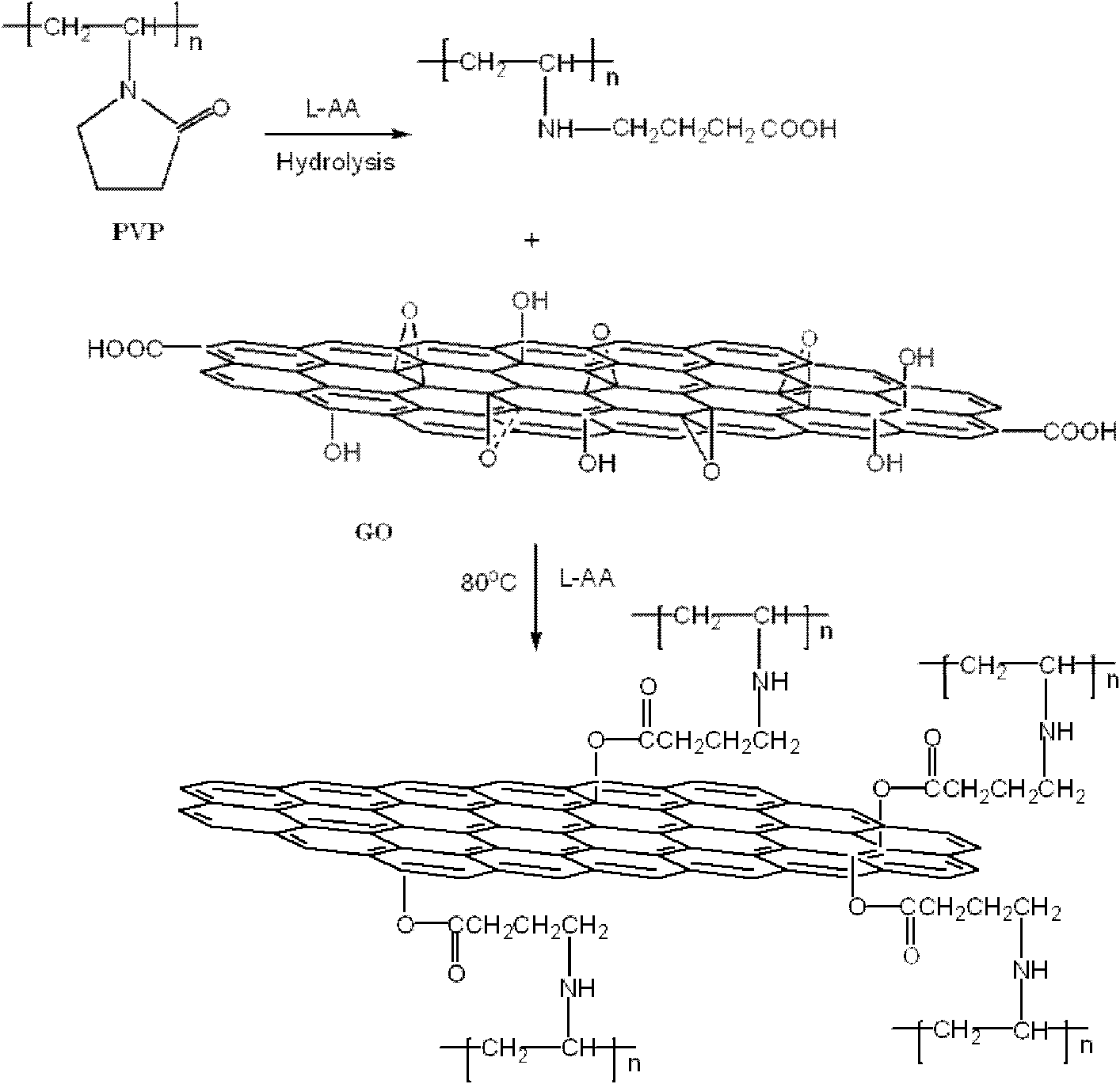

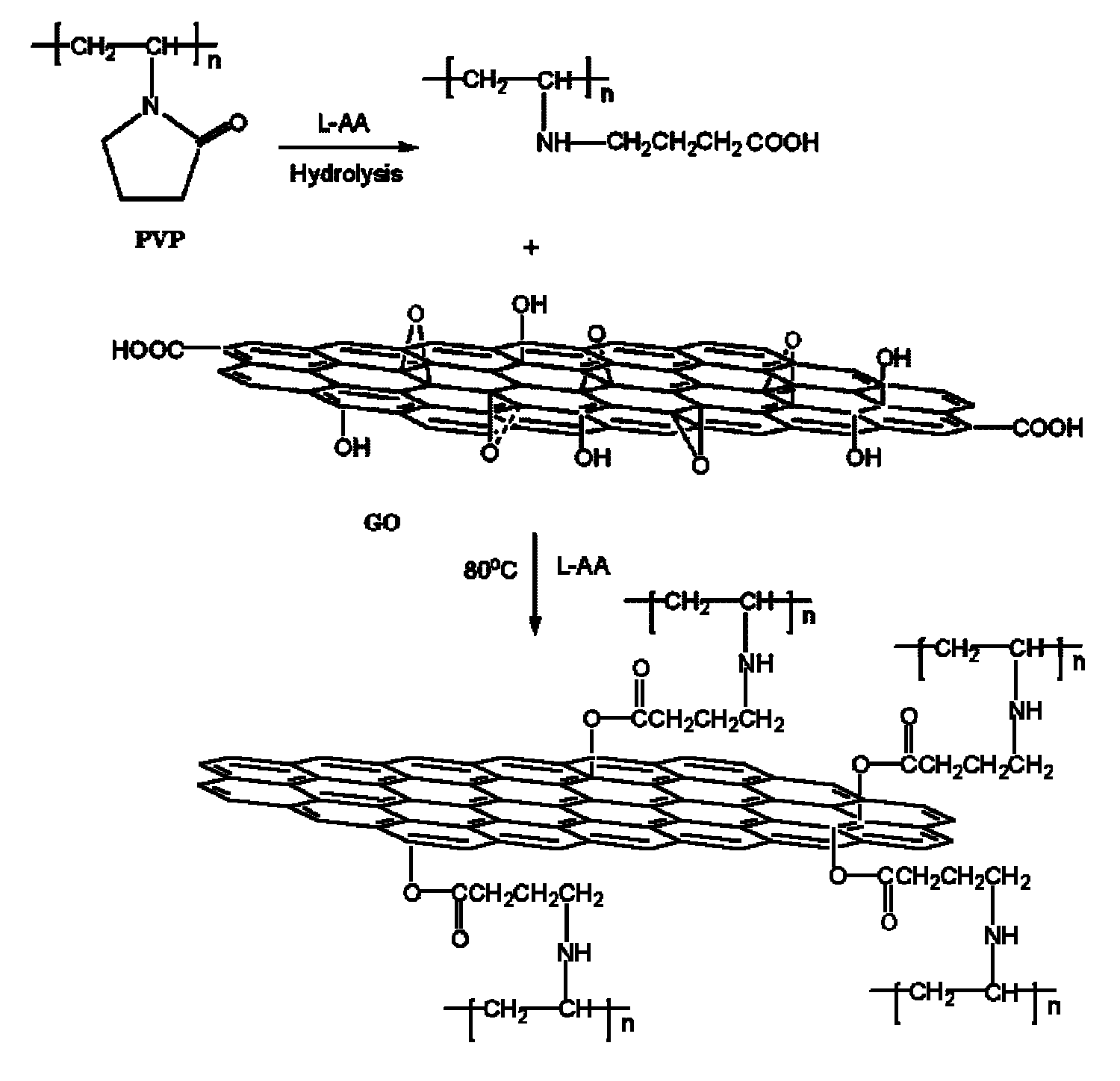

[0023] Such as figure 1 As shown, the preparation method described in this embodiment comprises the following steps:

[0024] 1. At room temperature, weigh 0.1g of laboratory-made graphite oxide and measure 200ml of H 2 O was added to a 250ml three-necked bottle, and the working frequency was 40kHz, and the ultrasonic power was 200w, and the ultrasonic treatment was performed for 30min to remove the graphite oxide and obtain a graphene oxide dispersion with a concentration of 0.5mg / ml.

[0025] 2. Weigh 1g of polyvinylpyrrolidone and add it into the graphene oxide dispersion, and then fully stir for 10 minutes to dissolve it.

[0026] 3. Weigh 0.4g of ascorbic acid and add it to the above system, stir it thoroughly for 5 minutes to dissolve it.

[0027] 4. Put the mixed system in an oil bath and heat it to 70°C. After fully reacting for 6 hours, a black uniform solution is obtained.

Embodiment 2

[0029] 1. At room temperature, weigh 0.2g of laboratory-made graphite oxide and measure 200ml of H 2 O was added to a 250ml three-necked bottle, and the working frequency was 40kHz, and the ultrasonic power was 200w, and the ultrasonic treatment was performed for 30min to remove the graphite oxide and obtain a graphene oxide dispersion with a concentration of 1mg / ml.

[0030] 2. Weigh 1g of polyvinylpyrrolidone and add it into the graphene oxide dispersion, and stir it fully for 10 minutes to dissolve it.

[0031] 3. Measure 1ml of hydrazine hydrate and add it to the above system, and stir thoroughly for 5 minutes to dissolve it.

[0032] 4. Put the mixed system in an oil bath and heat it to 80°C. After fully reacting for 4 hours, a black uniform solution is obtained.

Embodiment 3

[0034] 1. At room temperature, weigh 0.02g of laboratory-made graphite oxide and measure 200ml of H 2 O was added to a 250ml three-necked bottle, and the working frequency was 40kHz, and the ultrasonic power was 200w, and the ultrasonic treatment was performed for 1 hour to remove the graphite oxide and obtain a graphene oxide dispersion with a concentration of 0.1mg / ml.

[0035] 2. Weigh 0.04g of polyvinylpyrrolidone and add it into the graphene oxide dispersion, then fully stir for 5 minutes to dissolve it.

[0036] 3. Weigh 0.02g of ascorbic acid and add it to the above system, stir it thoroughly for 5 minutes to dissolve it.

[0037] 4. Put the mixed system in an oil bath and heat it to 90°C. After fully reacting for 2 hours, a black uniform solution is obtained.

[0038] In the preparation process of graphene grafted with polyvinylpyrrolidone on the surface, the optimal amount of polyvinylpyrrolidone was determined by adjusting the amount of polyvinylpyrrolidone to be 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com