Cast titanium alloy for oral restoration

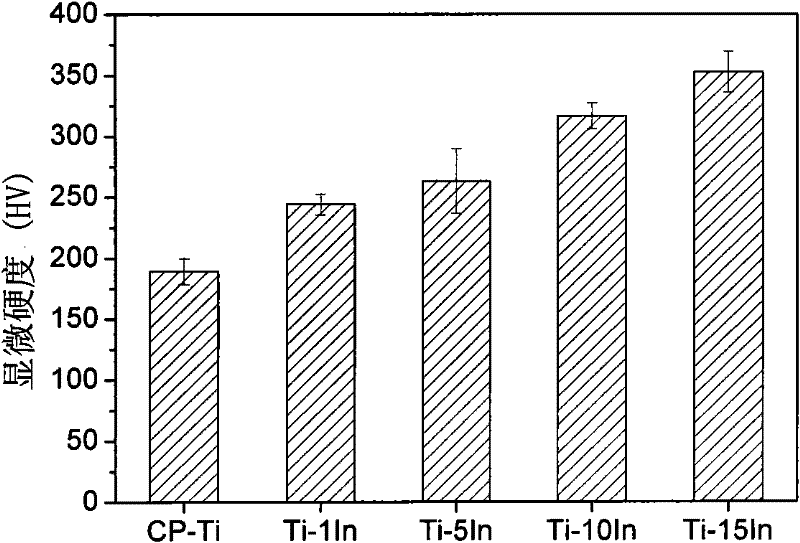

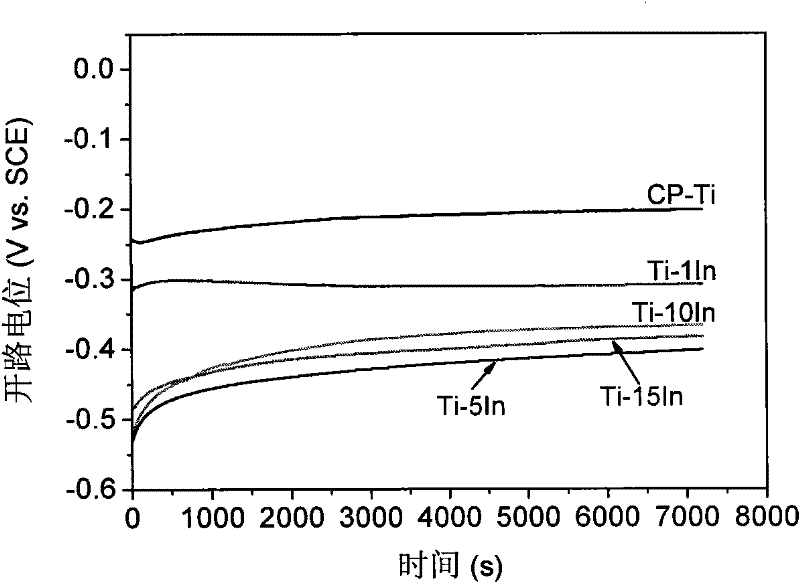

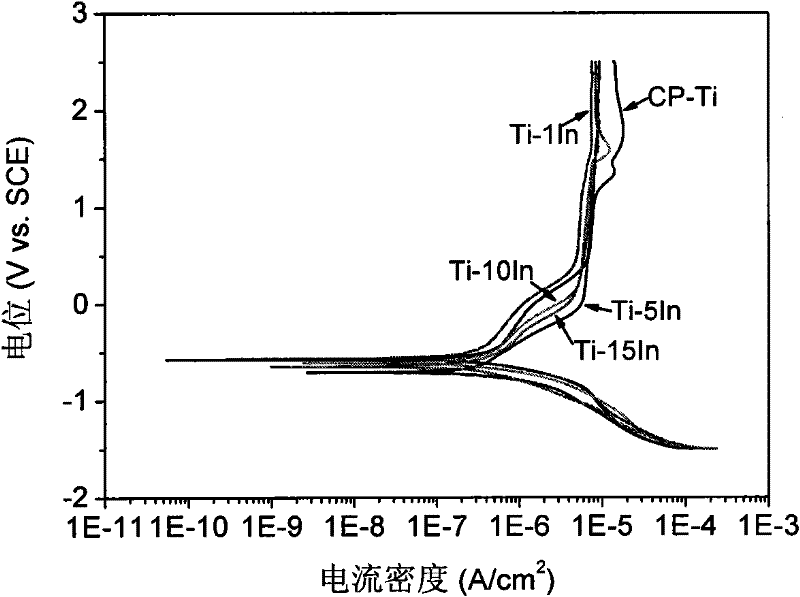

A technology of casting titanium alloy and oral restoration, which is applied in the field of oral medical materials, can solve problems not related to alloys, achieve excellent corrosion resistance, reduce replacement times and costs, and improve microhardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The alloy material is configured with sponge titanium and indium blocks as raw materials, and the design masses of each component are: titanium (Ti) 29.29g, indium (In) 0.71g. An alloy ingot was smelted in a vacuum electric arc furnace, and then the ingot was solution treated at 850° C. for 1 hour and quenched. The quenched alloy ingot is hot-rolled to a thickness of 1-2 mm.

Embodiment 2

[0026] The alloy material is configured with sponge titanium and indium blocks as raw materials, and the design masses of each component are: titanium (Ti) 26.64g, indium (In) 3.36g. An alloy ingot was smelted in a vacuum electric arc furnace, and then the ingot was solution treated at 850° C. for 1 hour and quenched. The quenched alloy ingot is hot-rolled to a thickness of 1-2mm.

Embodiment 3

[0028] The alloy material is configured with titanium sponge and indium blocks as raw materials, and the design masses of each component are: titanium (Ti) 23.69g, indium (In) 6.31g. An alloy ingot was smelted in a vacuum electric arc furnace, and then the ingot was solution treated at 850° C. for 1 hour and quenched. The quenched alloy ingot is hot-rolled to a thickness of 1-2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com