Solar silicon cell nanosecond-pulse green laser scriber

A technology of nanosecond pulses and silicon batteries, applied in laser welding equipment, circuits, electrical components, etc., can solve the problems of large spot, wide scratches, and large deviation of resonance absorption frequency, etc., and achieve uniform distribution of spot intensity, The effect of reducing the spot diameter and increasing the power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

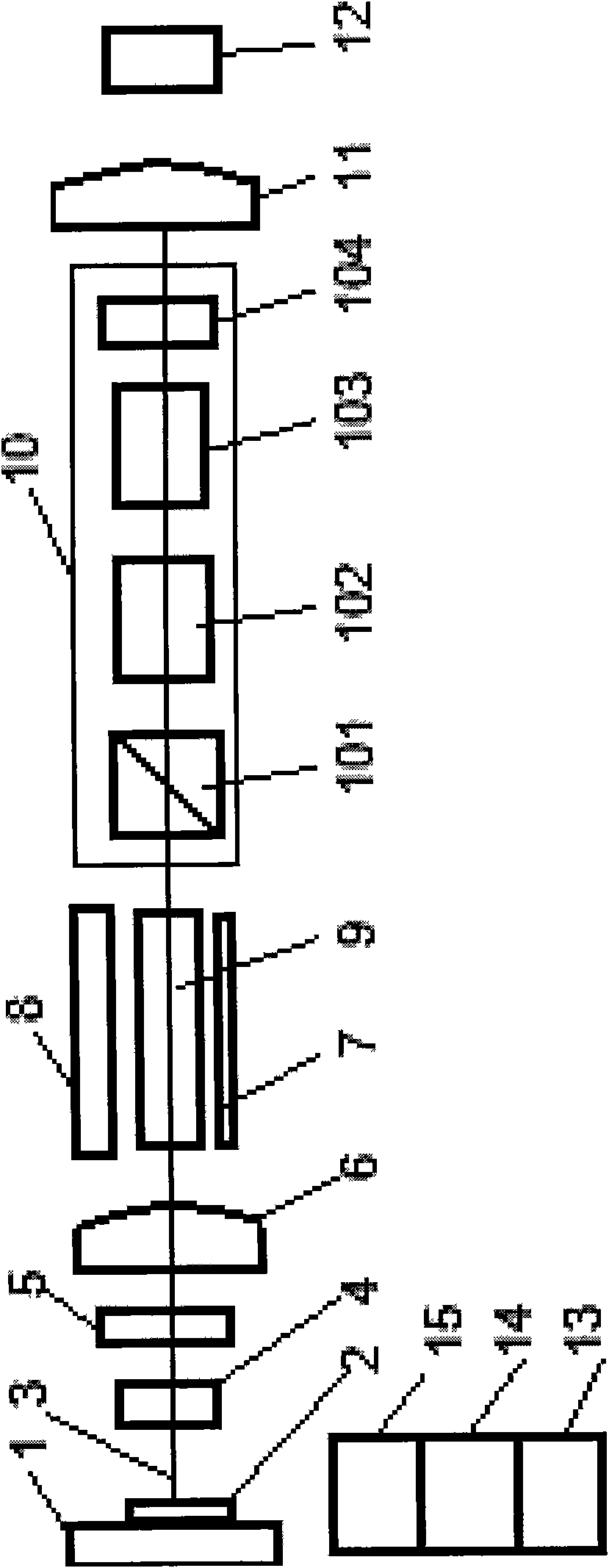

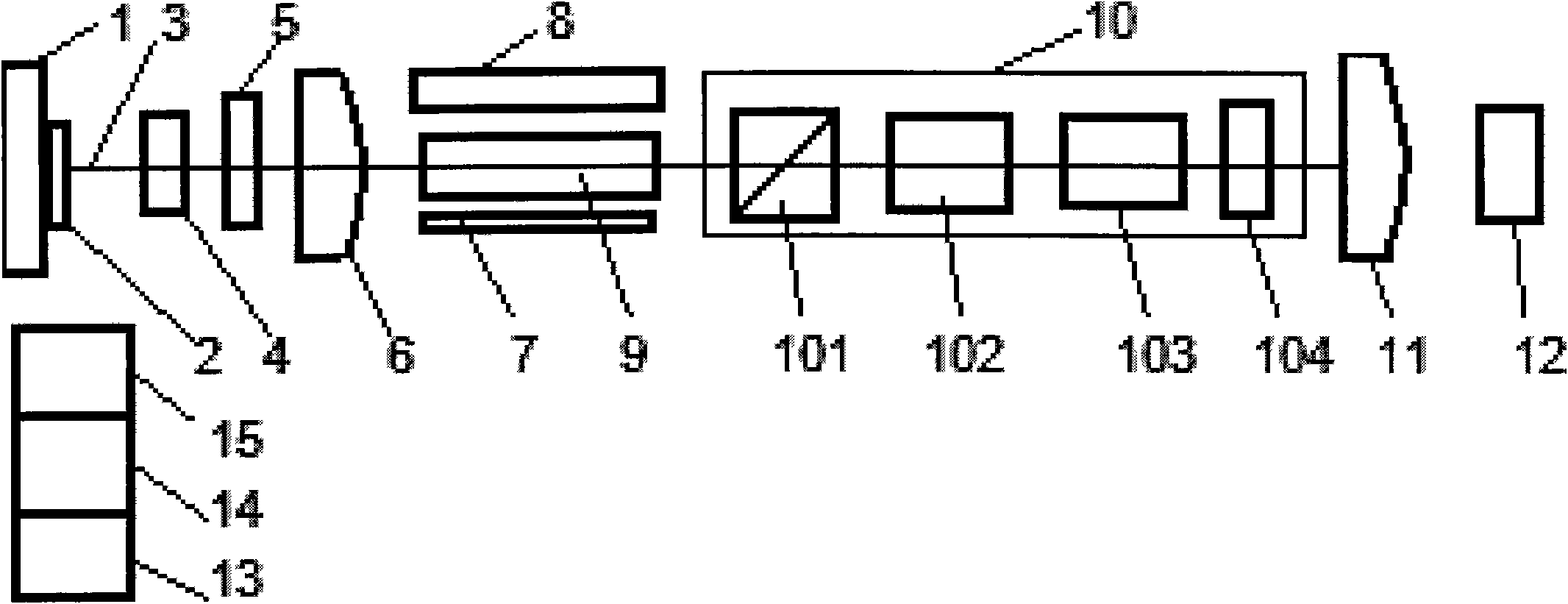

[0013] see figure 1 The nanosecond pulsed green laser scribing device for solar silicon cells includes laser components and a two-dimensional electric shift stage 1 on its output optical path 3 , water cooling components 13 , laser power supply 14 and machine control components 15 . in,

[0014] The laser component includes a total anti-cavity plate, a Q switcher, a laser rod 9 and an output cavity plate arranged in sequence on the laser oscillating circuit. Wherein: the output cavity sheet is a Gaussian mirror 6, and the total anti-cavity sheet is a concave mirror 11 complementary to the Gaussian mirror 6; the Q switcher is an electro-optical Q switcher 10, which is connected in series on the laser oscillation circuit A polarizer 101, a first Q-switching crystal 102, a second Q-switching crystal 103 and a 1 / 4 wave plate 104, the first Q-switching crystal 102 and the second Q-switching crystal 103 are gallium lanthanum silicate crystals, here Gallium lanthanum silicate cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com