Rubber jacketed flexible cable shield material for wind generation and preparation method thereof

A cable sheath material and flexible cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of single improvement of flexibility performance, single improvement of cold resistance performance, and inability to take into account cold protection and flexibility at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

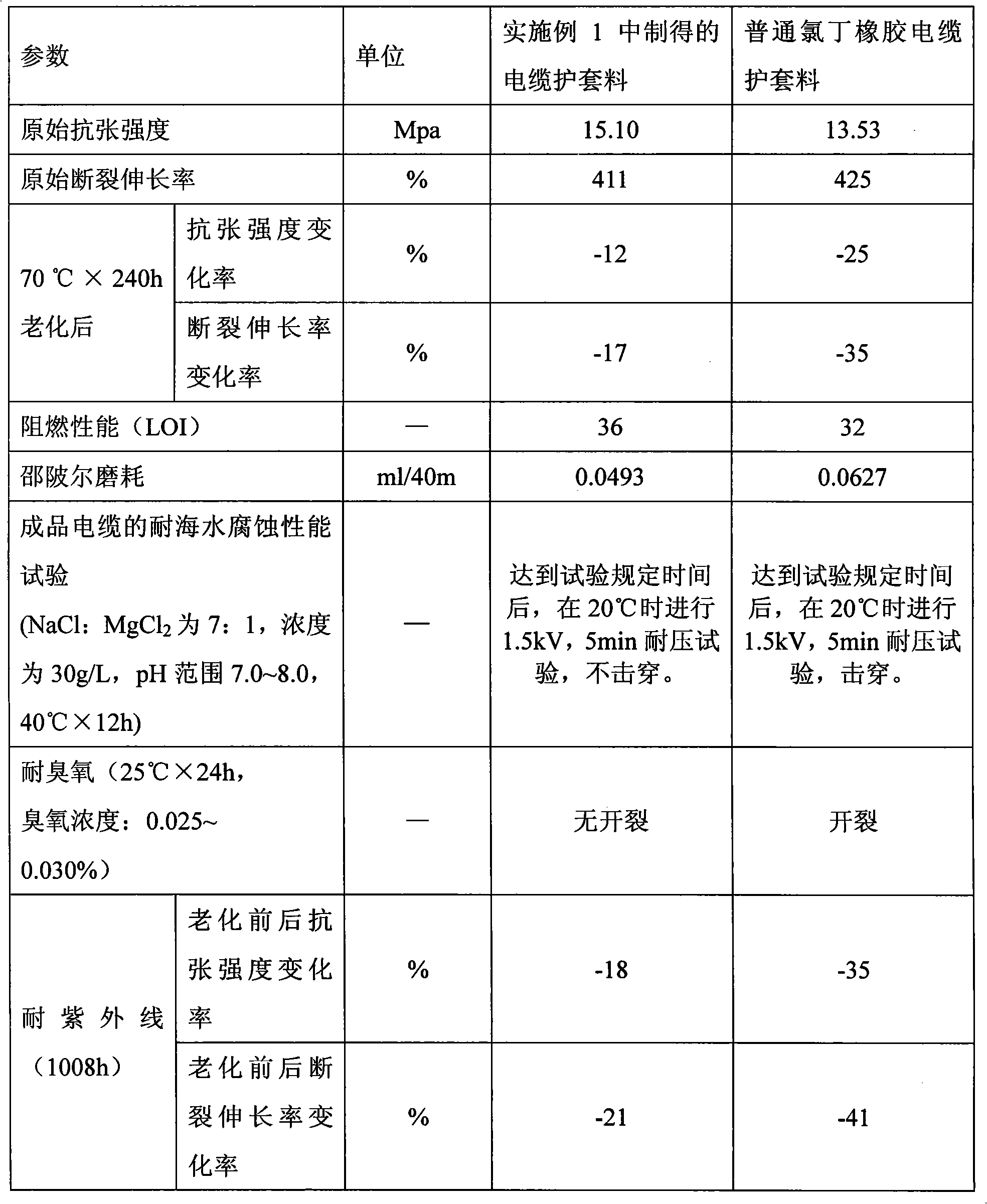

Embodiment 1

[0040] 1. Rubber sheath flexible cable sheath material for wind power generation, based on 100kg of low-temperature resistant chloroprene rubber, anti-aging agent (ODA 6kg), softener (DOP 15kg), reinforcing filler (active reinforcing agent 50kg), coupling agent (SI-692kg) and vulcanizing agent (zinc oxide).

[0041] 2. The preparation method is:

[0042] 1) In order to ensure uniform mixing, a multi-stage mixing process is adopted. The first stage internal mixer uses low-speed mixing, the mixing temperature does not exceed 100°C, and the mixing time is about 12 to 14 minutes.

[0043] 2) The vulcanizing agent is added in the second stage, the amount of vulcanizing agent added is 5.5kg, the internal mixer is mixed at a low speed, the mixing temperature does not exceed 90°C, and the mixing time is about 2.5 to 4 minutes.

[0044] 3) In order to ensure the smooth surface of the extrusion sheath, the above compounded materials must be parked for 24 hours before extrusion, and the...

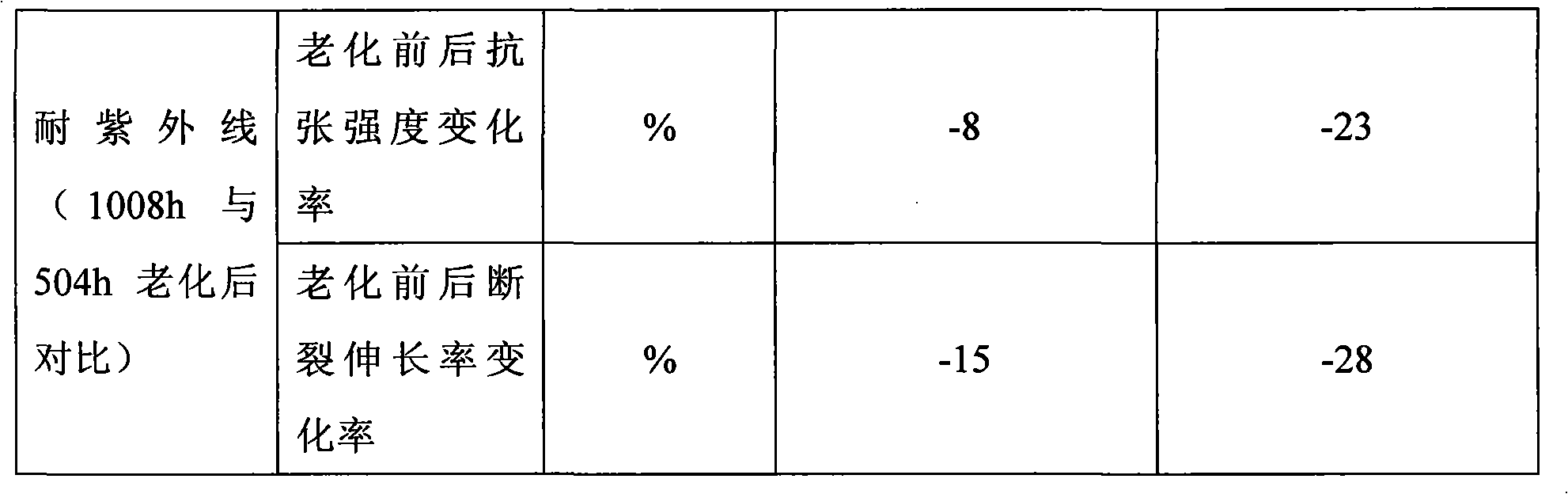

Embodiment 2

[0051] 1. Rubber sheath flexible cable sheathing material for wind power generation, based on 100kg of low-temperature resistant chloroprene rubber, anti-aging agent (D, 3kg), softener (DOS, 20kg), reinforcing filler (talc powder, 40kg), and occasionally Joint agent (KH-550, 1kg) and vulcanizing agent (zinc oxide).

[0052] 2. The preparation method is:

[0053] 1) In order to ensure uniform mixing, a multi-stage mixing process is adopted. The first stage internal mixer uses low-speed mixing, the mixing temperature does not exceed 100°C, and the mixing time is 14 minutes;

[0054] 2) The vulcanizing agent is added in the second stage, the amount of vulcanizing agent added is 6.0kg, the internal mixer is mixed at a low speed, the mixing temperature is 80°C, and the mixing time is 2.5 minutes;

[0055] 3) In order to ensure the smooth surface of the extrusion sheath, the above compounded materials must be parked for 24 hours before extrusion, and the third re-remixing is carrie...

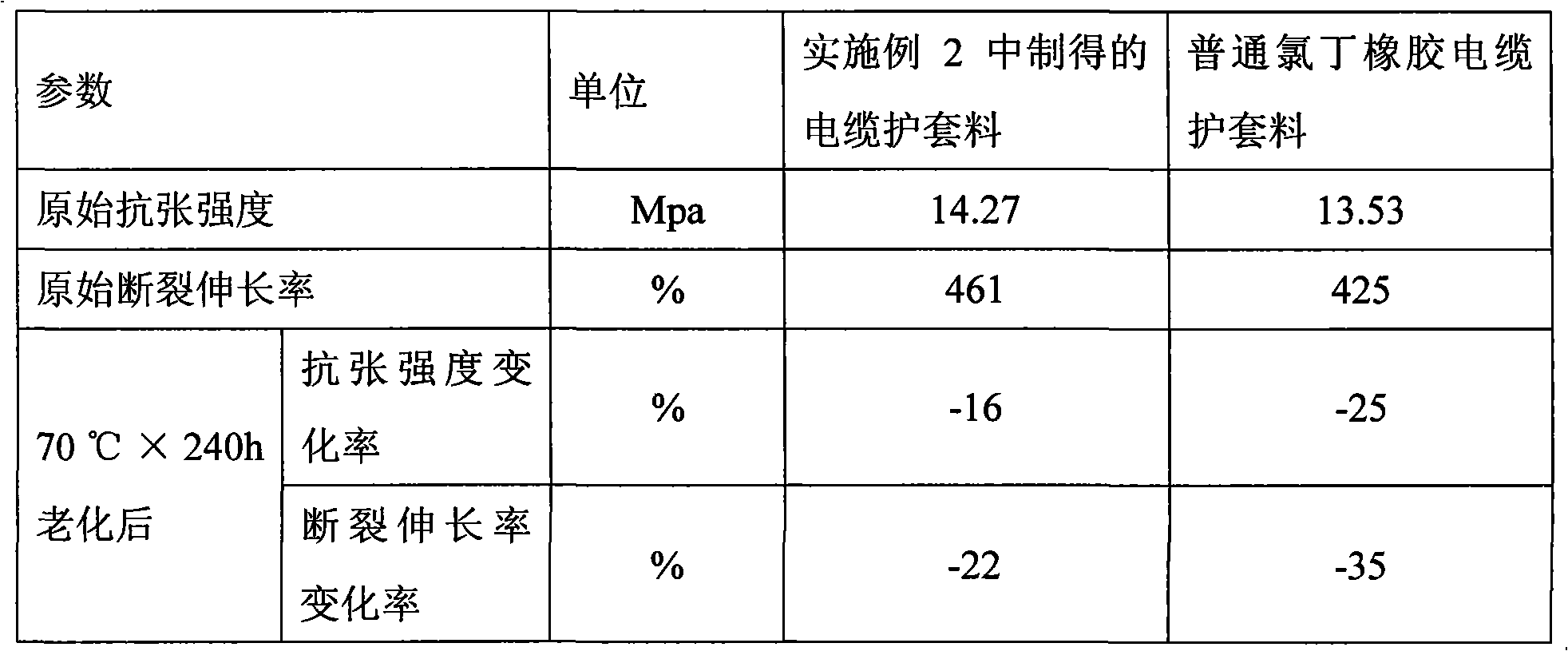

Embodiment 3

[0062] 1. Rubber sheath flexible cable sheath material for wind power generation, based on 100kg of low-temperature resistant chloroprene rubber, anti-aging agent (4010, 5kg), softener (DOS, 18kg), reinforcing filler (white carbon black, 60kg), Coupling agent (A-172, 1.8kg) and vulcanizing agent (zinc oxide).

[0063] 2. The preparation method is:

[0064]1) In order to ensure uniform mixing, a multi-stage mixing process is adopted. The first stage internal mixer uses low-speed mixing, the mixing temperature does not exceed 100°C, and the mixing time is 13 minutes;

[0065] 2) The vulcanizing agent is added in the second stage, the amount of vulcanizing agent added is 5.8kg, the internal mixer is mixed at a low speed, the mixing temperature does not exceed 90°C, and the mixing time is 2.5 minutes;

[0066] 3) In order to ensure the smooth surface of the extrusion sheath, the above compounded materials must be parked for 24 hours before extrusion, and the third re-remixing is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com