Non-contact image measuring system

An image measurement, non-contact technology, used in measurement devices, instruments, optical devices, etc., to achieve high efficiency, ensure the reliability of focusing, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

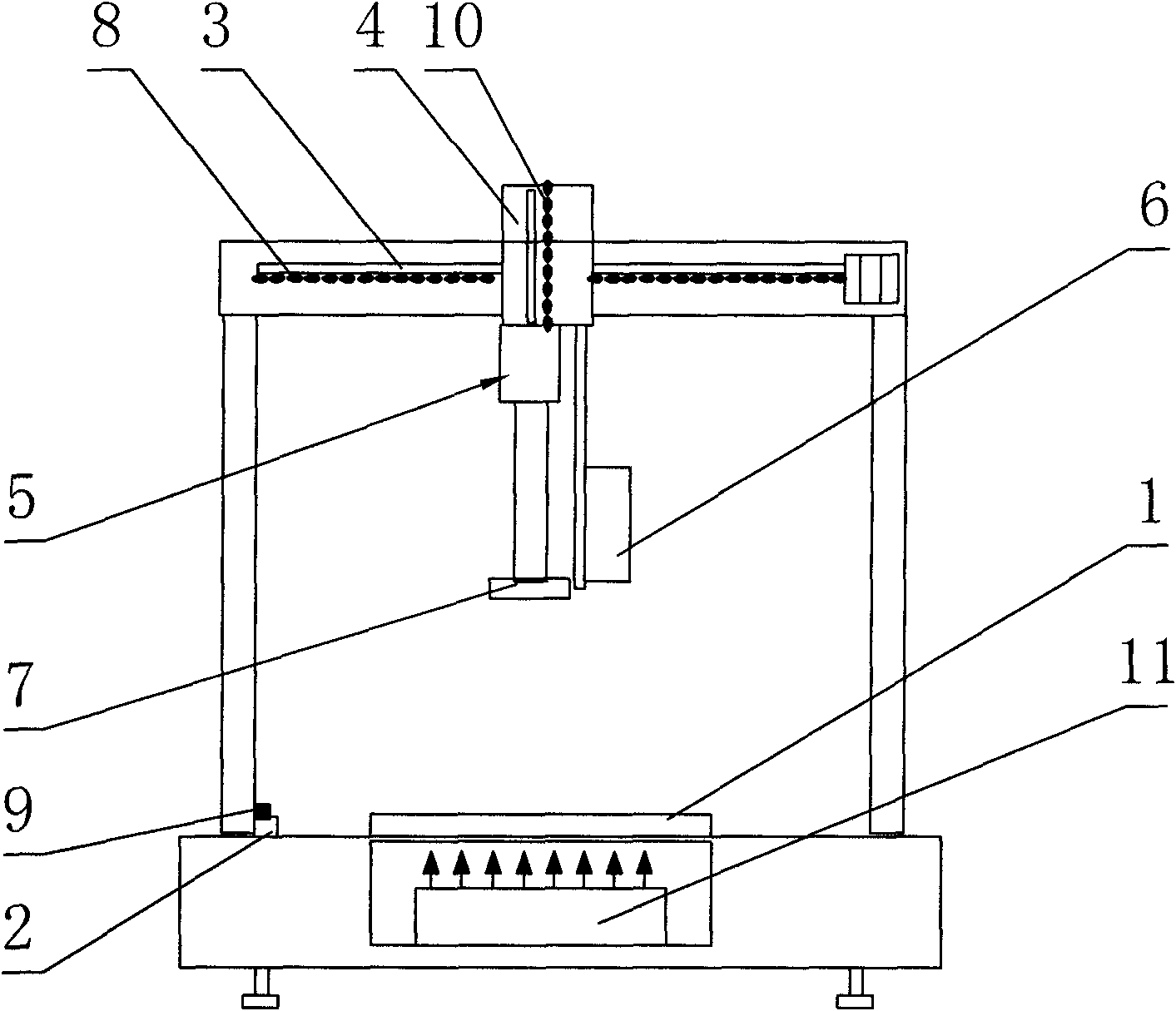

[0020] figure 1 It is a structural schematic diagram of the present invention. As shown in the figure, a non-contact image measurement system includes a three-dimensional workbench, an image measurement device, a laser ranging device, a grating data acquisition device and a motion control device. The three-dimensional workbench includes a worktable 1, a Y-axis guide rail 2 set on the worktable 1, an X-axis guide rail 3 parallel to the top of the worktable 1 and can slide along the vertical direction of the Y-axis guide rail 2, and a Z-axis guide perpendicular to the working plane. 4. The image measurement device includes an image acquisition card and a camera 5 that is arranged at the bottom of the Z-axis guide rail 4 and can move up and down along the Z-axis guide rail 4. The lens 7 of the camera 5 is vertically corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com