X-ray radiographic digital imaging detection method for power grid GIS (Geographic Information System) equipment

A detection method and digital imaging technology, applied in the direction of using radiation for material analysis, etc., to achieve the effect of reducing the number of photos and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Determine that the part to be photographed is the isolation switch of the power grid GIS equipment;

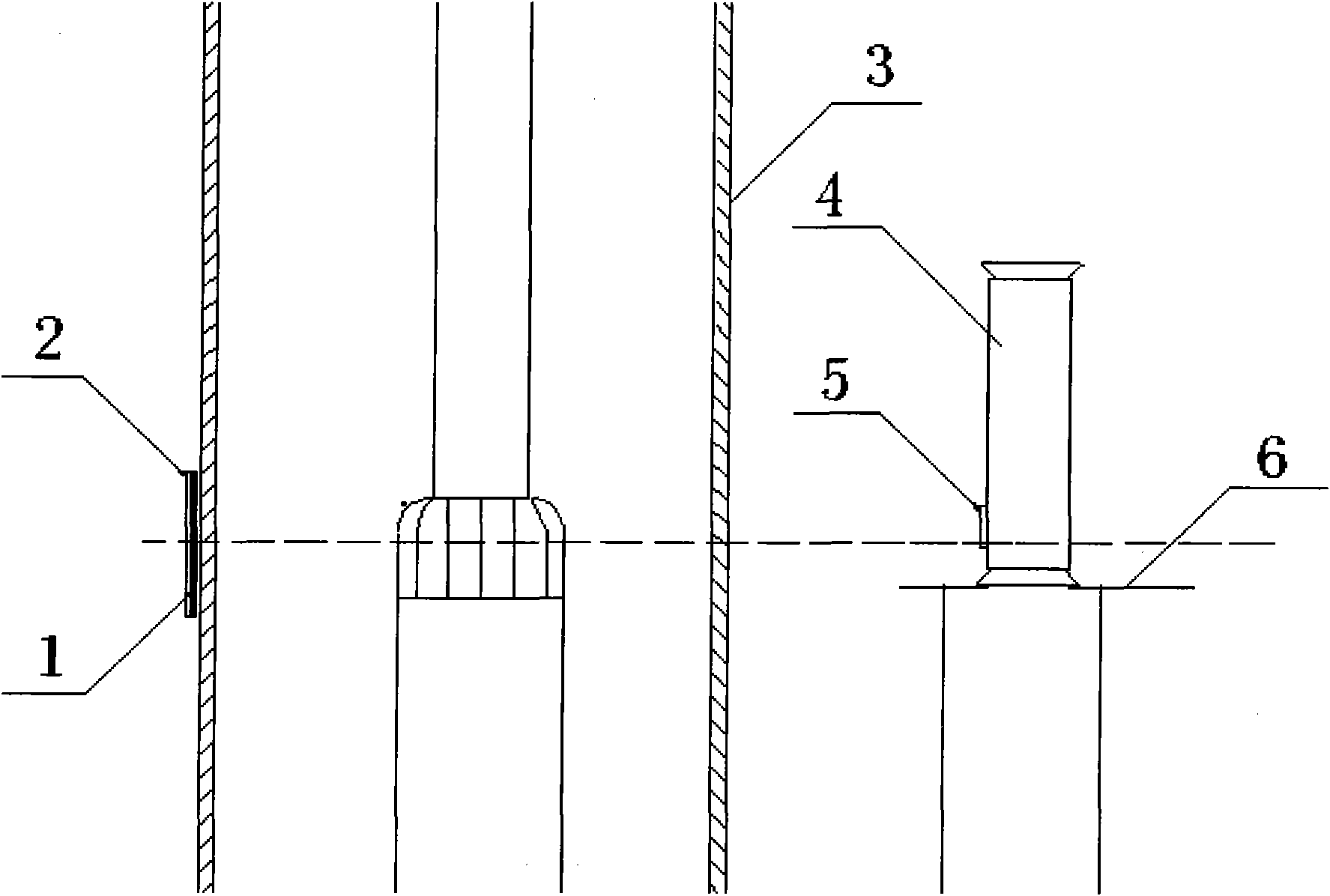

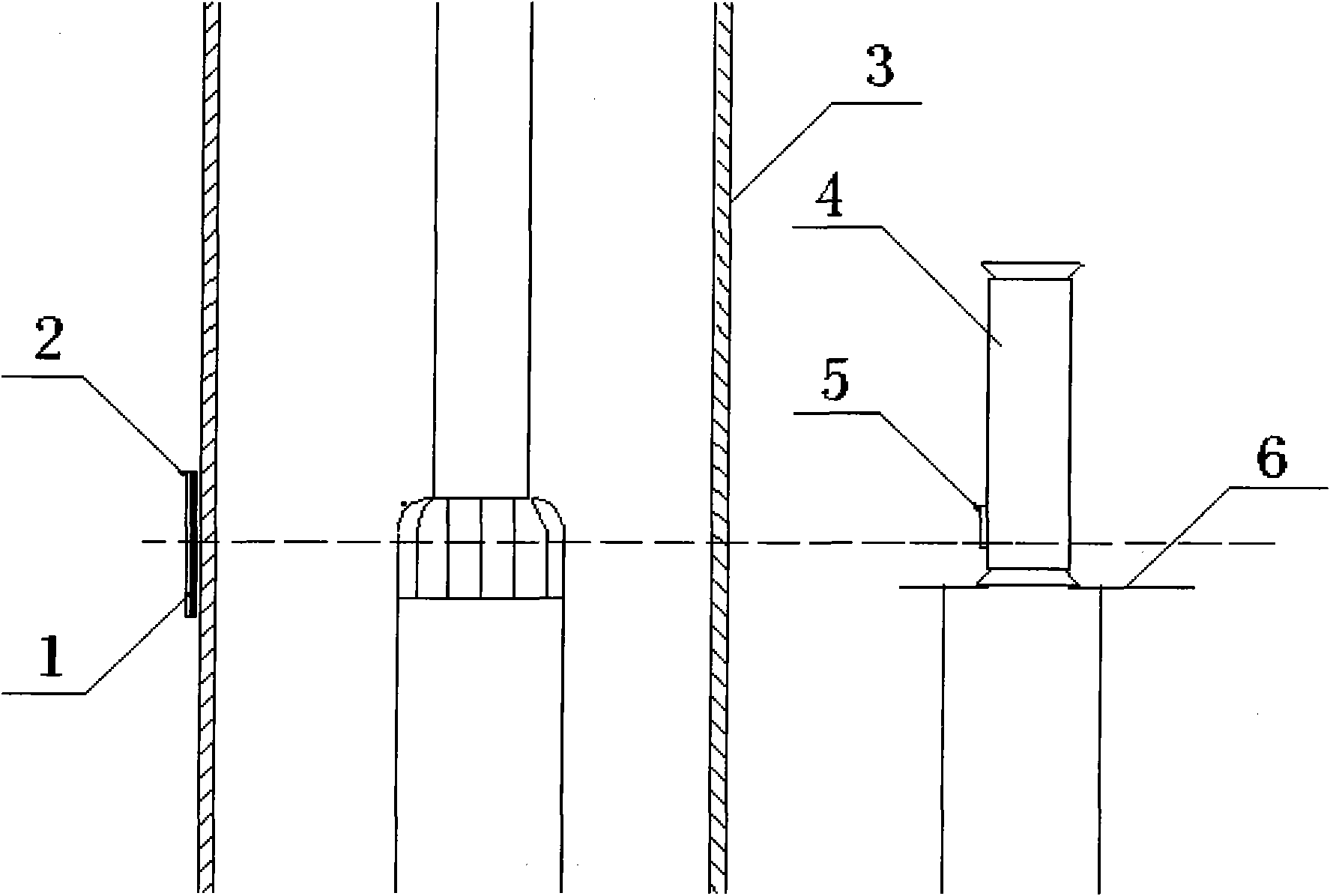

[0041] 2) Erecting of the X-ray machine 4 and placement of the X-ray photosensitive imaging plate 1 Place the X-ray machine 4 fixed on the X-ray machine bracket 6 firmly on the shooting platform so that the ray emission window 5 is vertically aligned with the area to be photographed. Part 3 is the isolation knife gate. The X-ray photosensitive imaging plate 1 is placed close to the equipment shell in the direction opposite to the radiation emission window 5 on the back of the isolation knife gate of the object to be photographed. The center of the radiation-sensitive imaging plate 1 is on a straight line;

[0042] 3) Connect the cables between the X-ray machine 1 and the console, and check that the console and the X-ray machine 4 are operating normally;

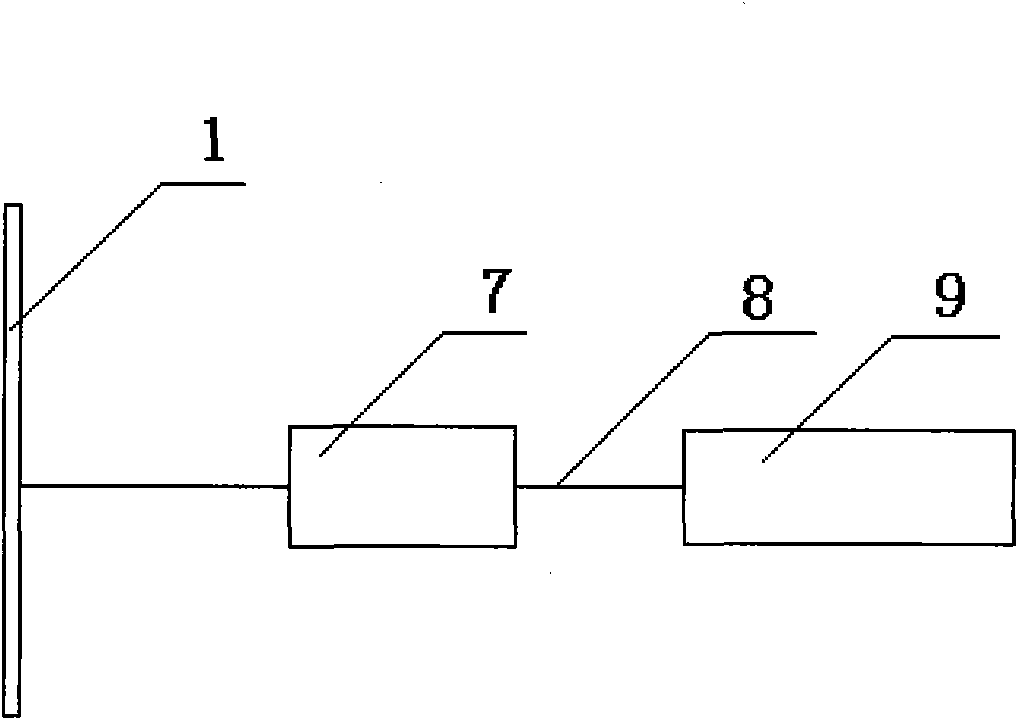

[0043] 4) Connect the CR digital image scanner 7 and the computer 9 through the dedicated data 8-wire, and check...

Embodiment 2

[0050] 1) Determine that the part to be photographed is a circuit breaker;

[0051] 2) Erecting of the X-ray machine 4 and placement of the X-ray photosensitive imaging plate 1 Place the X-ray machine 4 fixed on the X-ray machine bracket 6 firmly on the shooting platform so that the ray emission window 5 is vertically aligned with the area to be photographed. Part 3 is the circuit breaker cylinder. The X-ray photosensitive imaging plate 1 is placed close to the equipment casing, namely the circuit breaker cylinder, on the back of the object to be photographed, that is, the back of the circuit breaker and the direction opposite to the radiation emission window 5. The center of the radiation emission window 5 is aligned with The equipment needs to shoot the part 3, and the center of the X-ray photosensitive imaging plate 1 is on a straight line;

[0052] 3) Connect the cables between the X-ray machine 1 and the console, and check that the console and the X-ray machine 4 are oper...

Embodiment 3

[0060] 1) Determine that the part to be photographed is the busbar barrel;

[0061] 2) Erecting of the X-ray machine 4 and placement of the X-ray photosensitive imaging plate 1 Place the X-ray machine 4 fixed on the X-ray machine bracket 6 firmly on the shooting platform so that the ray emission window 5 is vertically aligned with the area to be photographed. Part 3 is the busbar cylinder body. Place the X-ray photosensitive imaging plate 1 close to the equipment casing in the direction opposite to the ray emission window 5 on the back of the object to be photographed. The center of the ray emission window 5 is in contact with the equipment to be photographed The center of the imaging plate 1 is on a straight line;

[0062] 3) Connect the cables between the X-ray machine 1 and the console, and check that the console and the X-ray machine 4 are operating normally;

[0063] 4) Connect the CR digital image scanner 7 and the computer 9 through the dedicated data 8-wire, and check...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com