Method for reconstructing residual stress field of profile of large-dimension fir-type blade wheel groove

A residual stress, fir-tree-shaped technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the public report of the method for reconstructing the residual stress field of the fir-tree-shaped blade root wheel groove surface. and other problems to achieve the effect of reducing consumption costs, improving production efficiency, and reducing the number of rolling treatments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

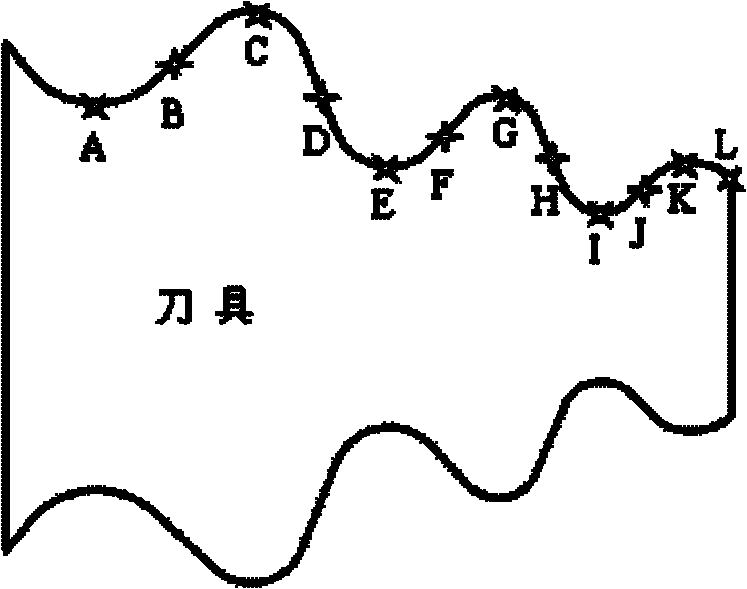

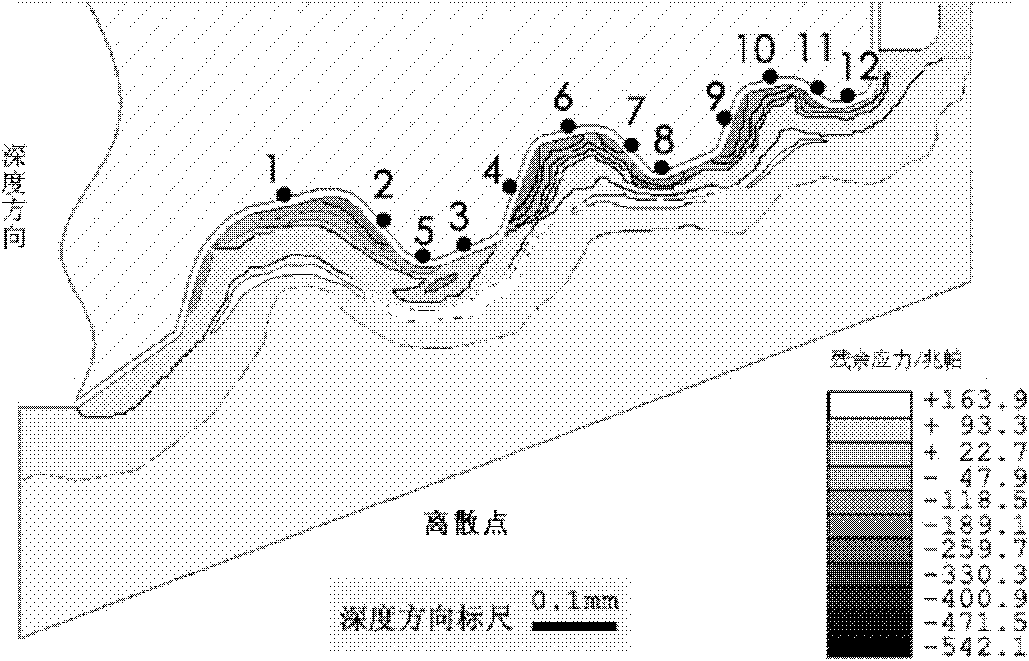

[0033] In this embodiment, a fir tree milling cutter with a diameter of 80 mm is used to process the wheel groove, and the reconstruction of the residual stress field of the wheel groove specifically includes the following steps:

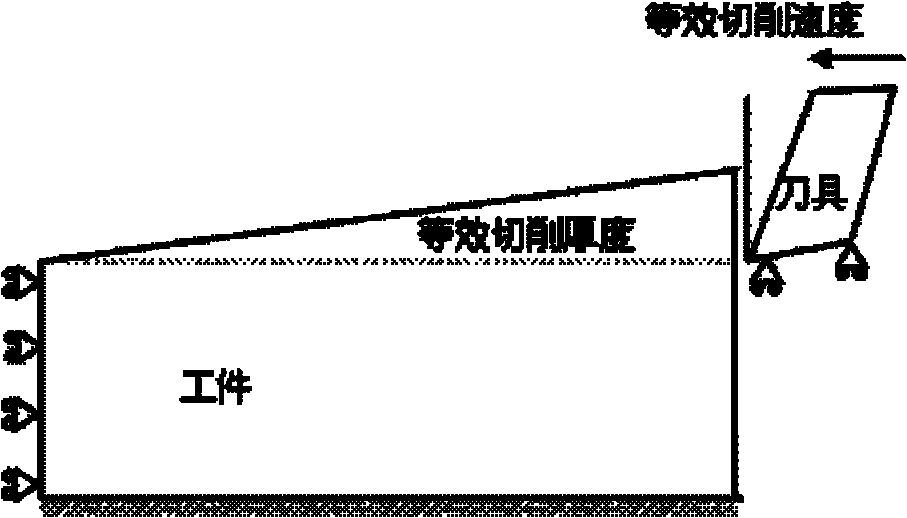

[0034] The first step is to take several discrete points on the root, middle and top of the wheel groove on the contour line of the fir-tree milling cutter as the detection points, using the principles of equivalent cutting speed, equivalent cutting thickness and equivalent feed per tooth , Get the equivalent cutting speed, equivalent cutting thickness and equivalent feed rate of standard cutting experiment with standard integral cylindrical end mill.

[0035] The said equivalent cutting speed is:

[0036]

[0037] among them:

[0038] n round Is the equivalent cutting speed, n Fir Is the rotation speed of fir tree milling cutter, d Fir Is the diameter of the fir tree milling cutter, d round Is the diameter of the cylindrical end mill, and v is the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com