Substrate heat processing apparatus

A technology for heat treatment devices and substrates, applied in optics, instruments, and optomechanical equipment, can solve the problems of time-consuming cooling tubes, limited bending of cooling tubes, and inability to reduce the thickness of cooling plates, so as to increase the number of storage, improve rigidity, The effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

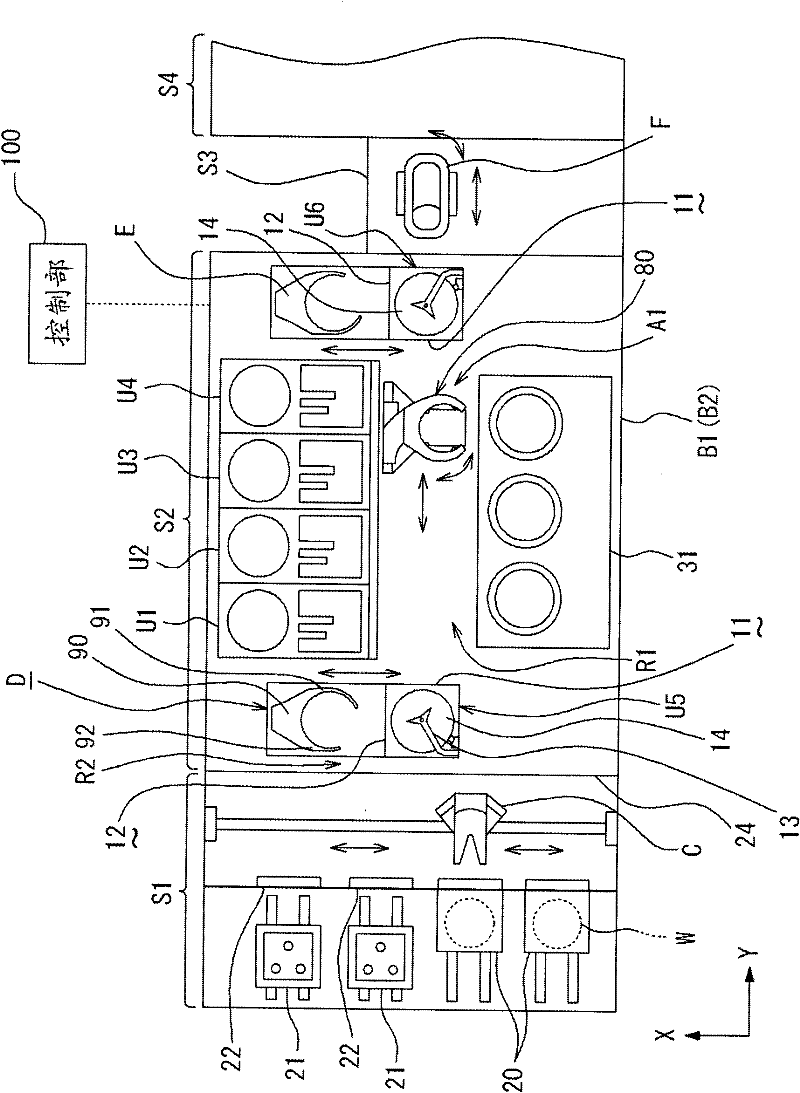

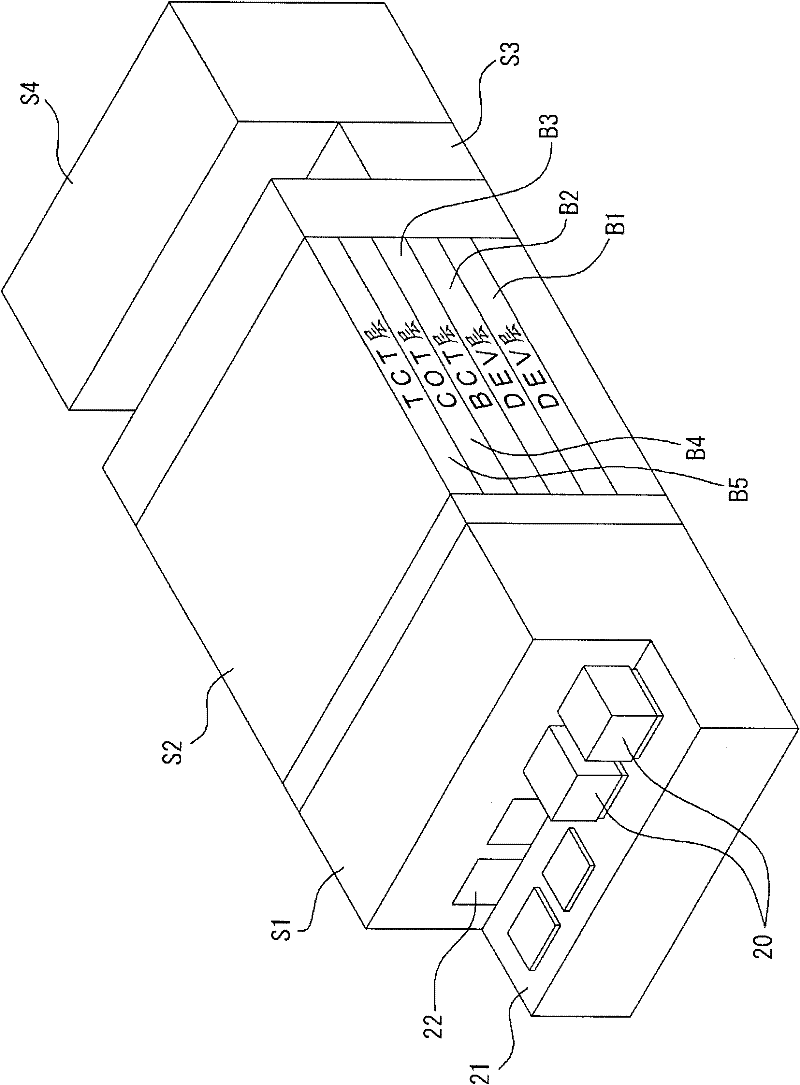

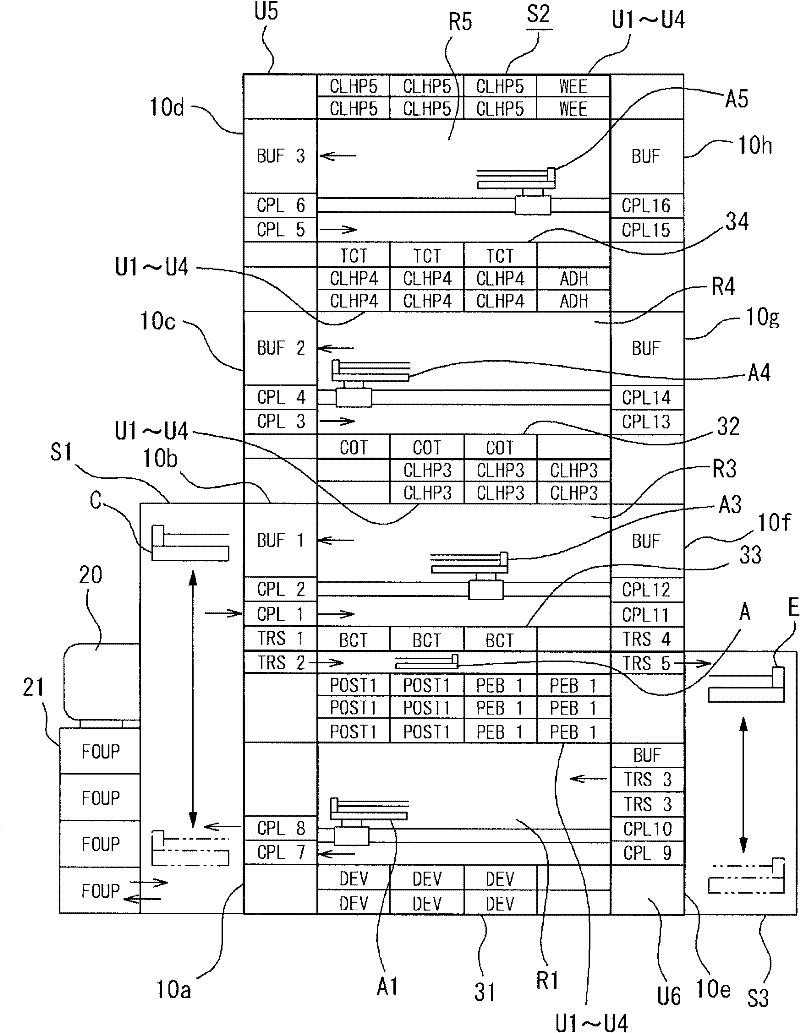

[0047] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. Here, a case where the substrate heat treatment apparatus of the present invention is applied to a resist coating / development processing apparatus for semiconductor wafers will be described.

[0048] The above-mentioned resist coating and developing treatment apparatus such as Figure 1 to Figure 8 As shown, it includes: carrier block S1, which is used for loading and unloading carrier 20, which is sealed and accommodated, for example, 13 semiconductor wafers W (hereinafter referred to as wafer W) as substrates; processing block S2, which is arranged vertically A plurality of, for example, five unit blocks B1 to B5; an interface block S3; and an exposure device S4 as a second processing block.

[0049] The above-mentioned carrier block S1 is provided with a mounting table 21 capable of mounting a plurality of (for example, 4) carriers 20, an opening and closing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com