Drying process for thenardite

Anhydrous Glauber's salt and drying process technology, applied in inorganic chemistry, alkali metal sulfite/sulfate dehydration, alkali metal sulfite/sulfite, etc., can solve unfavorable large-scale production, low purity of Glauber's salt, Large harvesting site and other issues, to achieve the effect of reducing production and operating costs, improving dryness and production capacity, and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

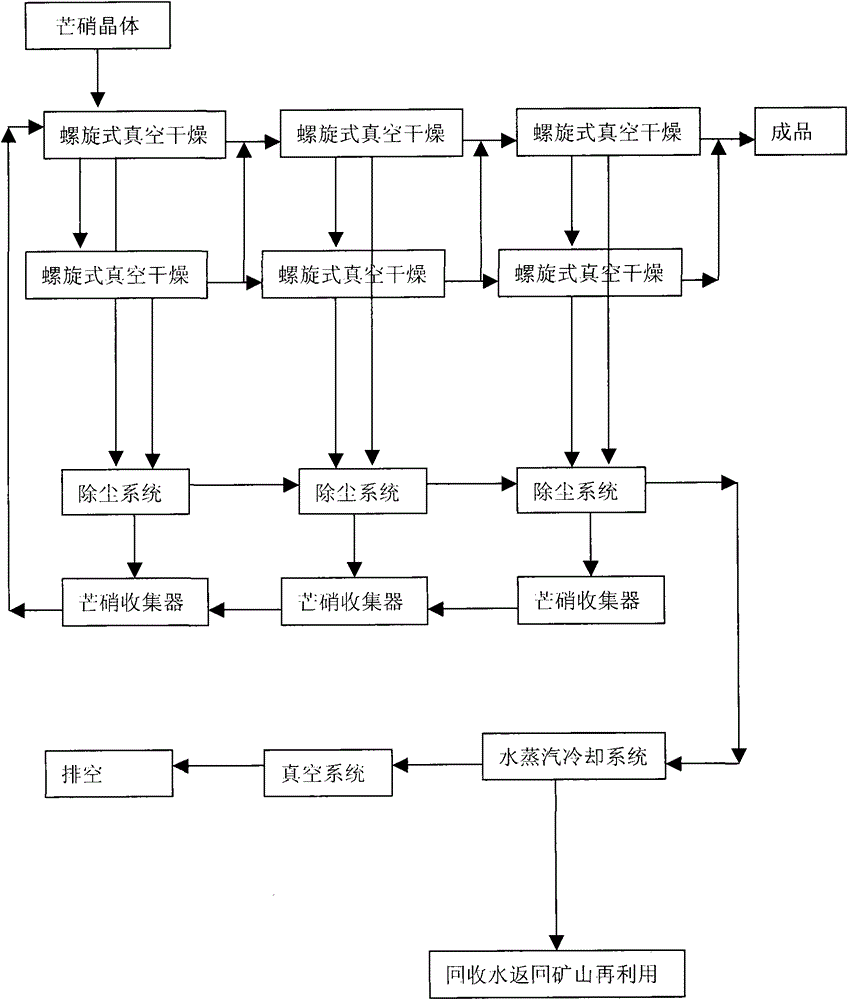

Method used

Image

Examples

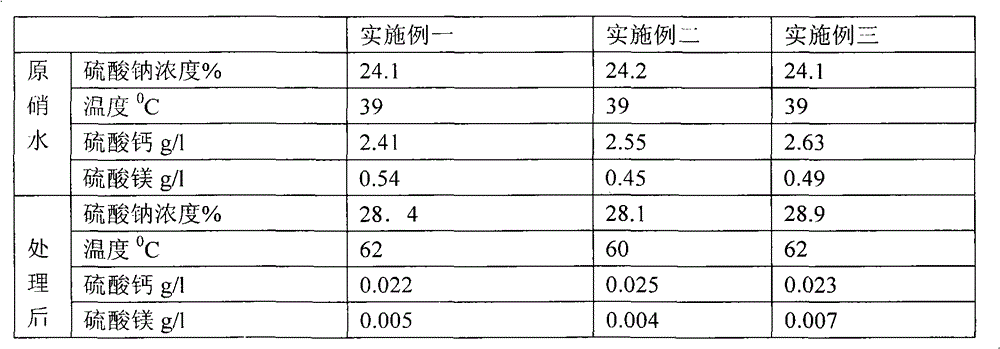

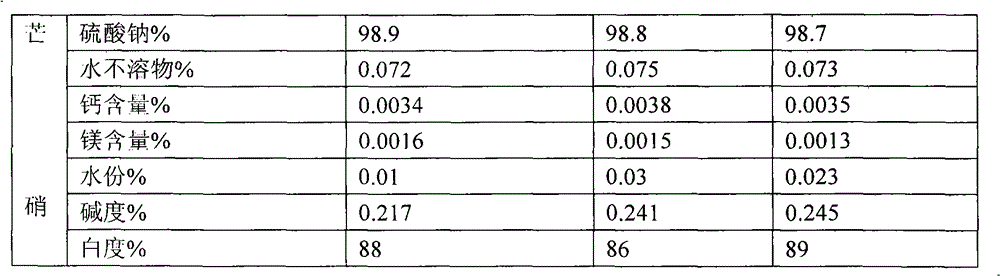

Embodiment 1

[0026] Under the monitoring of the DCS automatic monitoring system, the 24°Be concentrated raw nitric water transported down the well passes through the first-stage pipeline filter to remove mechanical impurities, and the third-stage ion exchanger is refined and purified to obtain refined nitric water with extremely low impurity content, and then input continuously Chemical crystallization process system to obtain high-concentration Glauber's salt crystal mixed liquid and input it into the first-stage centrifuge for dehydration to obtain Glauber's salt crystals containing less than 2.0% free water, and then input it into a three-stage spiral vacuum dryer for drying. The drying temperature is controlled at 150°C. Enter the automatic packaging system for packaging, inspection, warehousing and sales. The various detection data obtained from Anhydrous Glauber's Salt will be shown in Table 1.

Embodiment 2

[0028] Under the monitoring of the DCS automatic monitoring system, the 24-30°Be concentrated raw nitric water transported down the well is passed through the first-stage pipeline filter to remove mechanical impurities, and the third-stage ion exchanger is refined and purified to obtain refined nitric water with extremely low impurity content. Input Continuous crystallization process system, the mixed liquid obtained with high-concentration Glauber's salt crystals is input into the first-stage centrifuge for dehydration to form Glauber's salt crystals containing 2.5% free water, and then input into the three-stage spiral vacuum dryer for drying, the drying temperature is controlled at 180°C and input into automation The packaging system carries out packaging, inspection, warehousing and sales. The various detection data obtained for Anhydrous Glauber's Salt will be shown in Table 1.

Embodiment 3

[0030]Under the monitoring of the DCS automatic monitoring system, the 24-30Be concentrated raw nitric water transported down the well is passed through the first-stage pipeline filter to remove mechanical impurities, and the third-stage ion exchanger is refined and purified to obtain refined nitric water with extremely low impurity content, and the input is continuous. Crystallization process system, the mixed liquid obtained with high concentration of thenardite crystals is input into the first-stage centrifuge for dehydration, forming thenardite crystals containing 3% free water, and then input into the three-stage spiral vacuum dryer for drying, the drying temperature is controlled at 200°C, and then input into automatic packaging The system carries out packaging, inspection, warehousing and sales. The various detection data obtained from Anhydrous Glauber's Salt will be shown in Table 1.

[0031]

[0032]

[0033] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com