Method for preparing solar energy absorbing layer material Cu2ZnSnS4 by hydrothermal synthesis

A technology of solar energy absorption and hydrothermal synthesis, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problems of difficulty in large-scale production, difficult control of components, high equipment requirements, and achieve good application prospects, low price, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

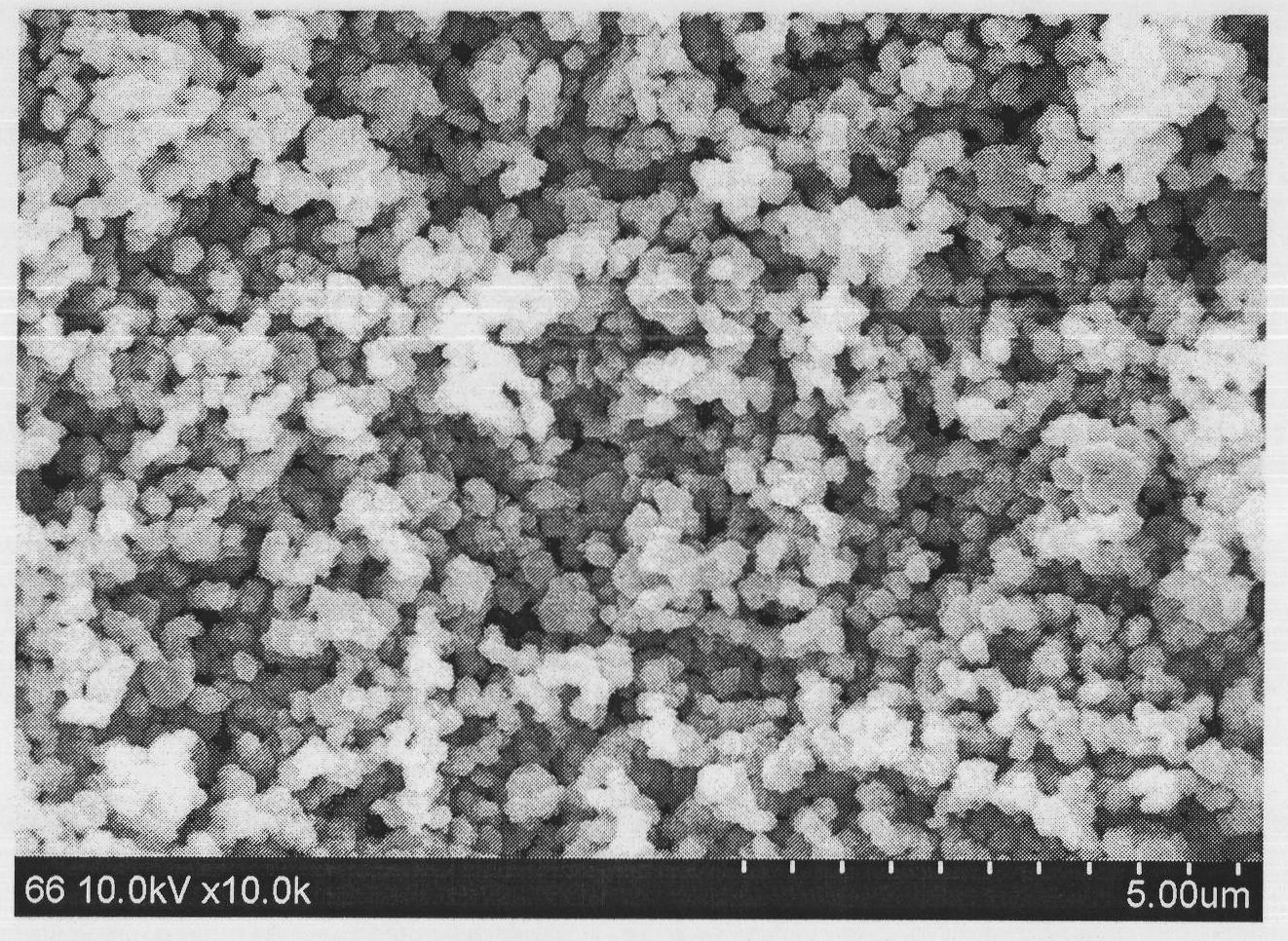

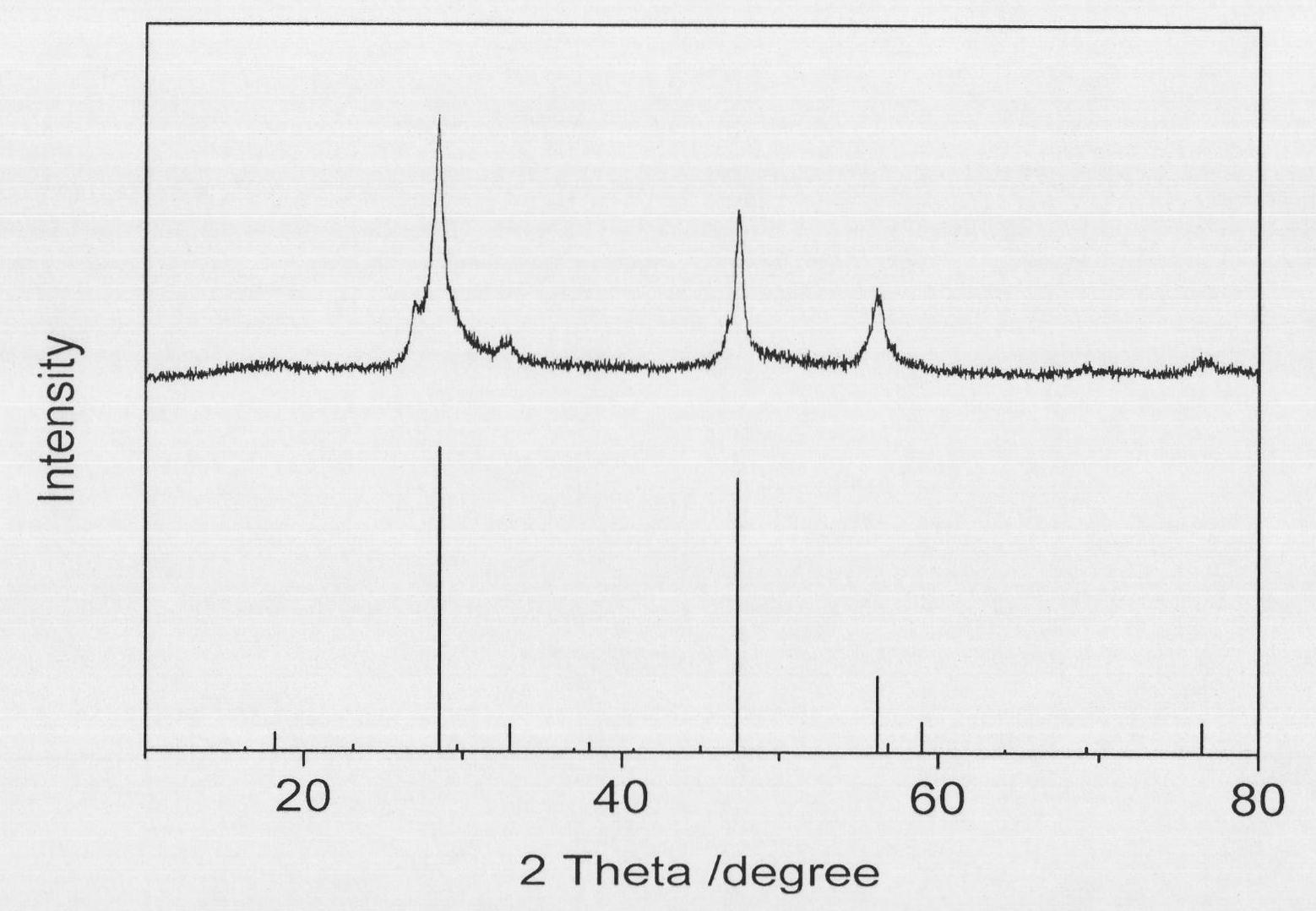

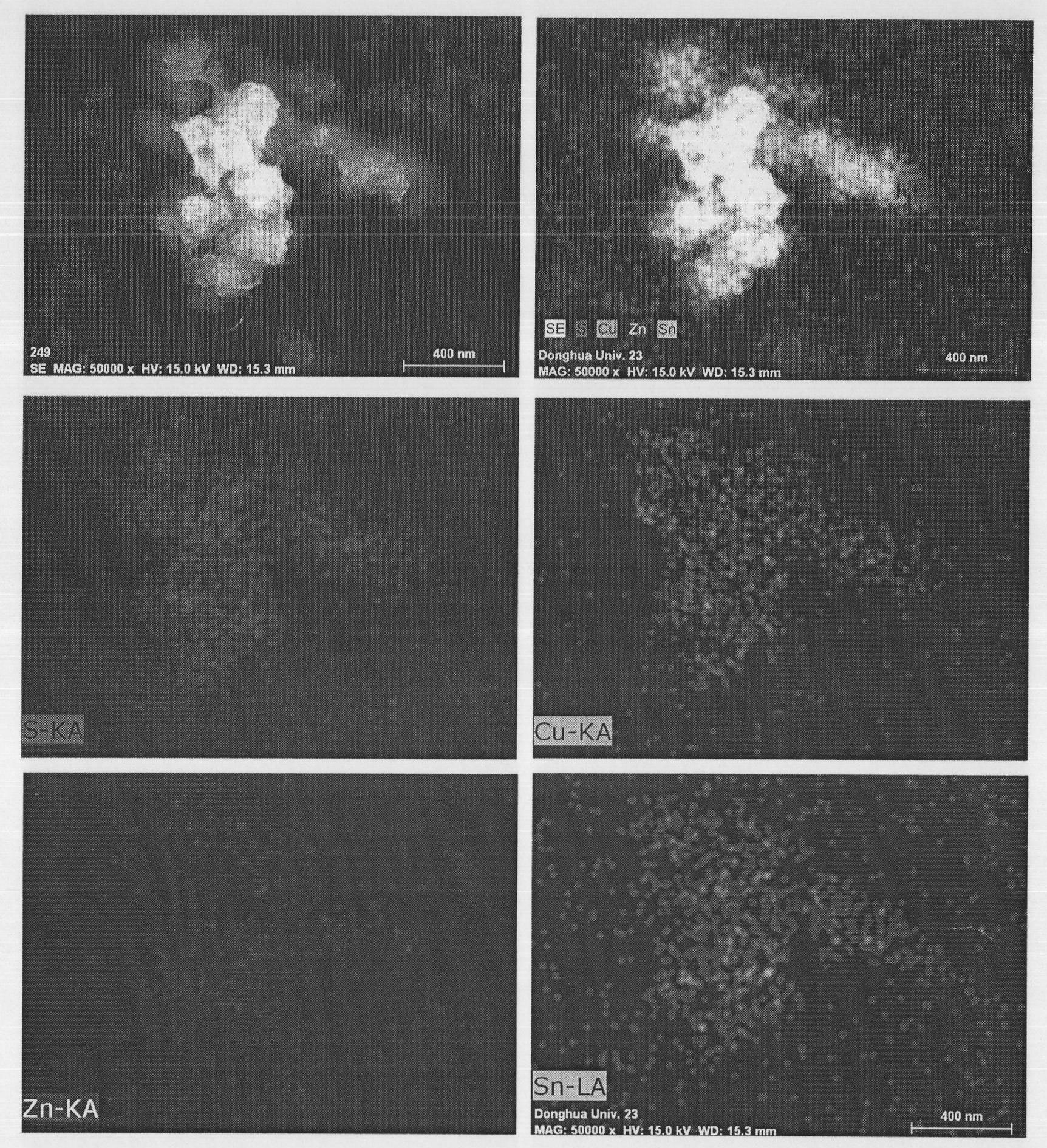

Embodiment 1

[0023] (A) Weigh 0.5mmol CuCl 2 2H 2 O, 0.25 mmol ZnSO 4 .7H 2 O, 0.25 mmol SnCl 2 .2H 2 O, put in a round bottom flask, add 10mL ethylene glycol, stir, and dissolve each substance. (B) Weigh 3mmol of Na 2 S, dissolved in 10mL ethylene glycol, ultrasonically dissolved. Pour B into A with stirring, continue to stir for half an hour, transfer to a high-pressure reactor, 180 ° C, 12 hours. After the reaction, centrifuge. to get Cu 2 ZnSnS 4 .

Embodiment 2

[0025] (A) Weigh 1mmol CuCl 2 2H 2 O, 0.5 mmol ZnSO 4 .7H 2 O, 0.5 mmol SnCl 2 .2H 2 O, put in a round bottom flask, add 10mL ethylene glycol, stir, and dissolve each substance. (B) Weigh 2mmol of Na 2 S, dissolved in 10mL ethylene glycol, ultrasonically dissolved. Pour B into A with stirring, continue to stir for half an hour, transfer to a high-pressure reactor, 200 ° C, 24 hours. After the reaction, centrifuge. to get Cu 2 ZnSnS 4 .

Embodiment 3

[0027] (A) Weigh 0.5mmol CuCl 2 2H 2 O, 0.25 mmol ZnSO 4 .7H 2 O, 0.25 mmol SnCl 2 .2H 2 O, put in a round bottom flask, add 10mL ethylene glycol, stir, and dissolve each substance. (B) Weigh 3mmol of Na 2 S, dissolved in 10mL ethylene glycol, ultrasonically dissolved. Pour B into A with stirring, continue to stir for half an hour, transfer to a high-pressure reactor, 220 ° C, 24 hours. After the reaction, centrifuge. to get Cu 2 ZnSnS 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com