Leadless X-ray protection plate and preparation method thereof

A protective plate and X-ray technology, which is applied in the field of X-ray radiation protection materials and its preparation, can solve the problems of poor radiation resistance of sulphoaluminate cement, affecting the strength and service life of the plate, and the heavy weight of the plate, so as to improve the protection against radiation. Radiation ability and corrosion resistance, good effect, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

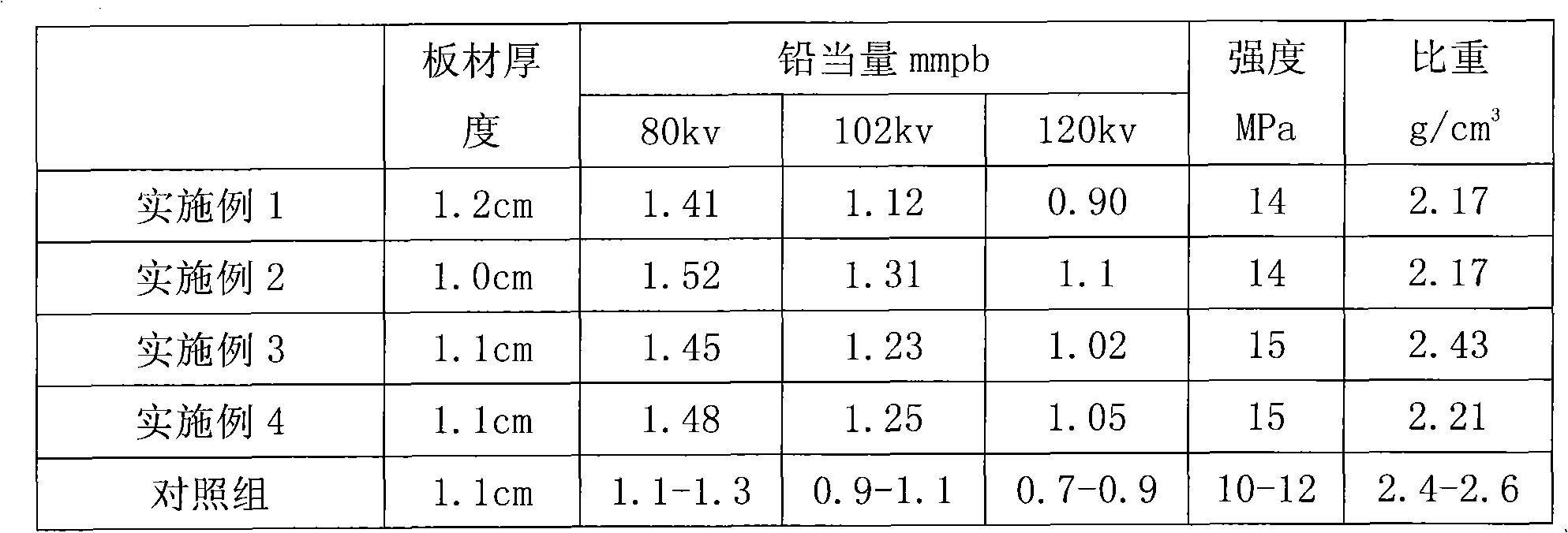

Examples

Embodiment 1

[0035] The lead-free X-ray protective board is made of the following raw materials in parts by weight: 40 parts of barium sulfate, 30 parts of barium-containing sulfoaluminate cement, 18 parts of pulp fiber, 10 parts of mica powder of 20-50 mesh, 100-200 mesh of oxidation 2 parts of aluminum powder, 3 parts of titanium dioxide, 3 parts of zinc oxide, 2 parts of sodium silicate, mica powder and alumina powder that do not meet the requirements of the mesh number and crushed to the required mesh number.

[0036] Its preparation method is:

[0037] (1) Add barium sulfate, barium-containing sulfoaluminate cement, mica powder, reinforcing fiber, alumina powder, titanium dioxide, zinc oxide and sodium silicate into the beater according to the proportion, so that the raw materials are fully mixed, and then add water Beating for 20 minutes to make a slurry with a concentration of 10-15wt%;

[0038] (2) injecting the above-mentioned slurry into a roller compactor to form a thin embryo,...

Embodiment 2

[0045] The lead-free X-ray protective board is made of the following raw materials in parts by weight: 50 parts of barium sulfate, 30 parts of barium-containing sulfoaluminate cement, 16 parts of 20-50 mesh mica powder, 7 parts of asbestos fiber, 100-200 mesh oxidation 5 parts of aluminum powder, 2 parts of titanium dioxide, 2 parts of zinc oxide, 5 parts of adhesive, mica powder and alumina powder that do not meet the requirements of the mesh number and crushed to the required mesh number. The adhesive is HDEP and cellulose acetate with a degree of polymerization between 140-250 and a degree of substitution between 1.8-2.5. The length of HDEP and cellulose acetate is between 8-15 mm and the diameter is between 15-20 μm. between.

[0046] Its preparation method is:

[0047] (1) Add barium sulfate, barium-containing sulfoaluminate cement, mica powder, asbestos fiber, alumina powder, titanium dioxide, zinc oxide, and adhesive to the beater according to the proportion, so that t...

Embodiment 3

[0055] The lead-free X-ray shield is made of the following raw materials by weight: 45 parts of barium sulfate, 40 parts of barium-containing sulfoaluminate cement, 17 parts of 20-50 mesh mica powder, 5 parts of pulp fiber, 100-200 mesh oxidation 3 parts of aluminum powder, 5 parts of titanium dioxide, 3 parts of zinc oxide, 4 parts of adhesive, mica powder and alumina powder that do not meet the specified mesh size and crushed to the required mesh size. The adhesive is epoxy resin 6101 And polypropylene EP300R, their length is between 8-15mm, and their diameter is between 15-20μm.

[0056] Its preparation method is:

[0057] (1) Add barium sulfate, barium-containing sulfoaluminate cement, mica powder, pulp fiber, alumina powder, titanium dioxide, zinc oxide and adhesive into the beater according to the proportion, so that the raw materials are fully mixed, and then add water Beating for 25 minutes to make a slurry with a concentration of 10-15wt%;

[0058] (2) injecting the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com