Method for producting propylene by catalytic pyrolysis of liquefied gas

A catalytic cracking and liquefied gas technology, which is applied in the production of bulk chemicals, organic chemistry, hydrocarbon cracking and hydrocarbon production, and can solve the problems of raw material sources and component limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

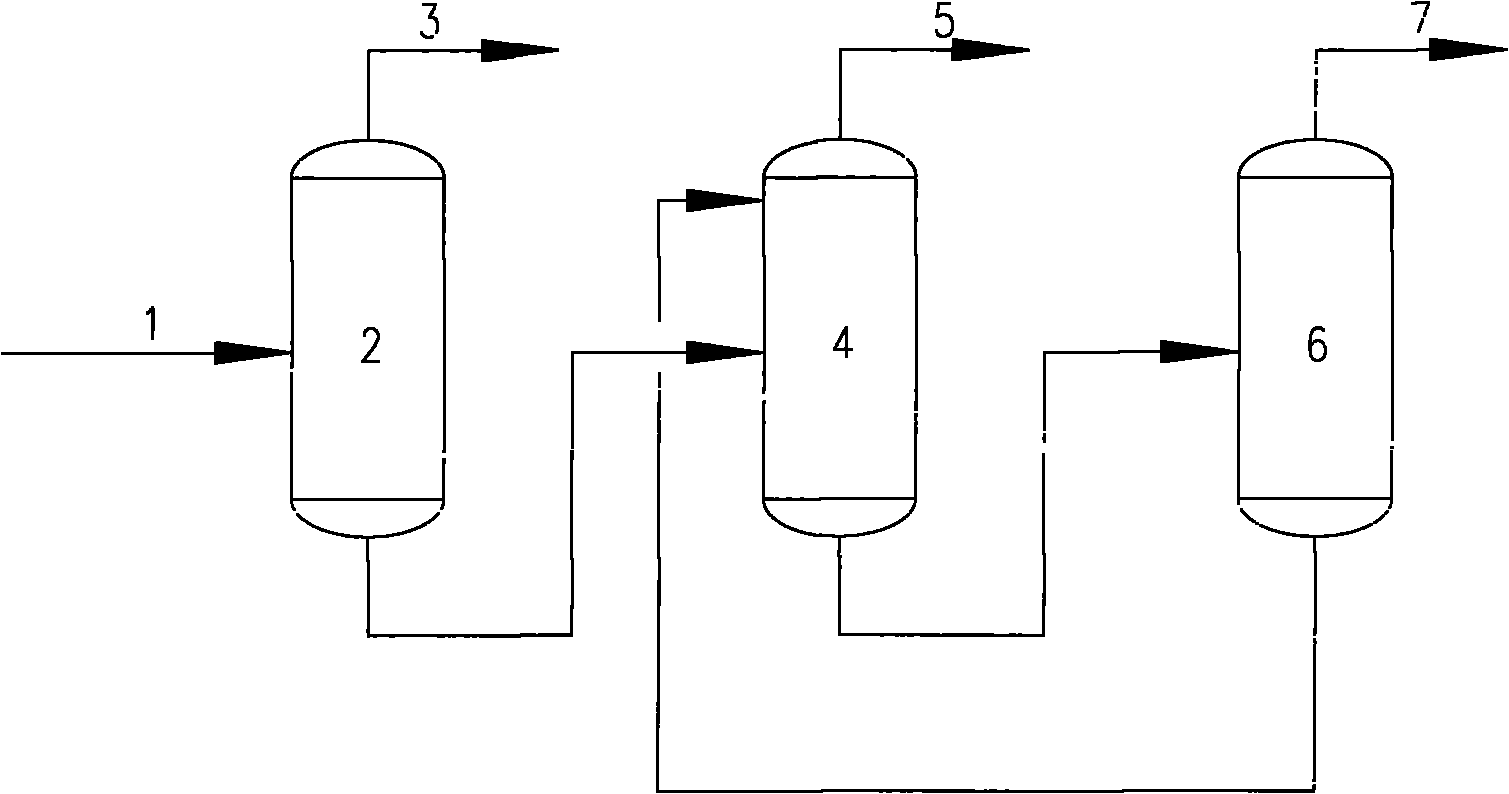

[0034] Refer to attached figure 1 , the liquefied gas raw material (1) is sent to the depropanizer (2) after being preheated to 89 ° C, after rectification, the C3 and below components (3) are obtained at the top of the tower, and the bottom product enters the extractive distillation tower (4) . The extraction agent of the extractive distillation tower is sulfolane and co-solvent (mass ratio can be adjusted), and the solvent ratio (7-8) is controlled to extract butane from the C4 fraction, and the butane (5) is obtained at the top of the tower, and the rich Butene-rich solvents. The rich solvent enters the stripper (6), and by ordinary rectification, butene is separated from the extractant, and at the top of the stripper, 96% (quality) carbon tetraolefins (7) are obtained, and the lean extractant at the bottom of the tower is passed through After cooling to 52°C, it is sent back to the top of the extractive distillation tower (4) for recycling.

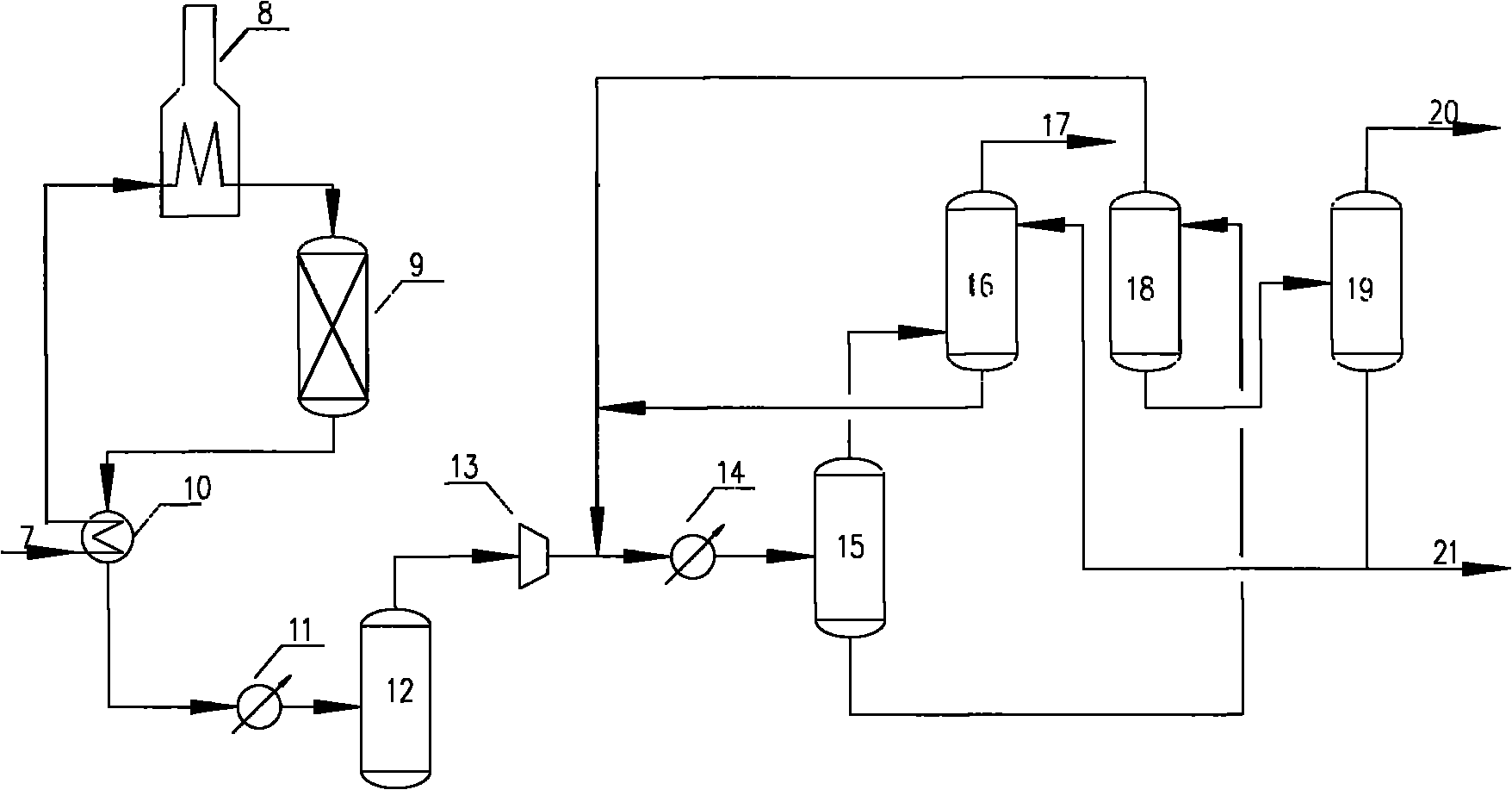

[0035] Refer to attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com