Energy-saving and emission-reducing device for coke dry quenching and energy-saving and emission-reducing coking process using same

A technology for energy saving, emission reduction and coke dry quenching. It is applied in coke ovens, gasification processes, and coke cooling. It can solve the problems of low heat utilization efficiency and no effect on carbon dioxide emission reduction, and achieve good industrial prospects and low costs. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

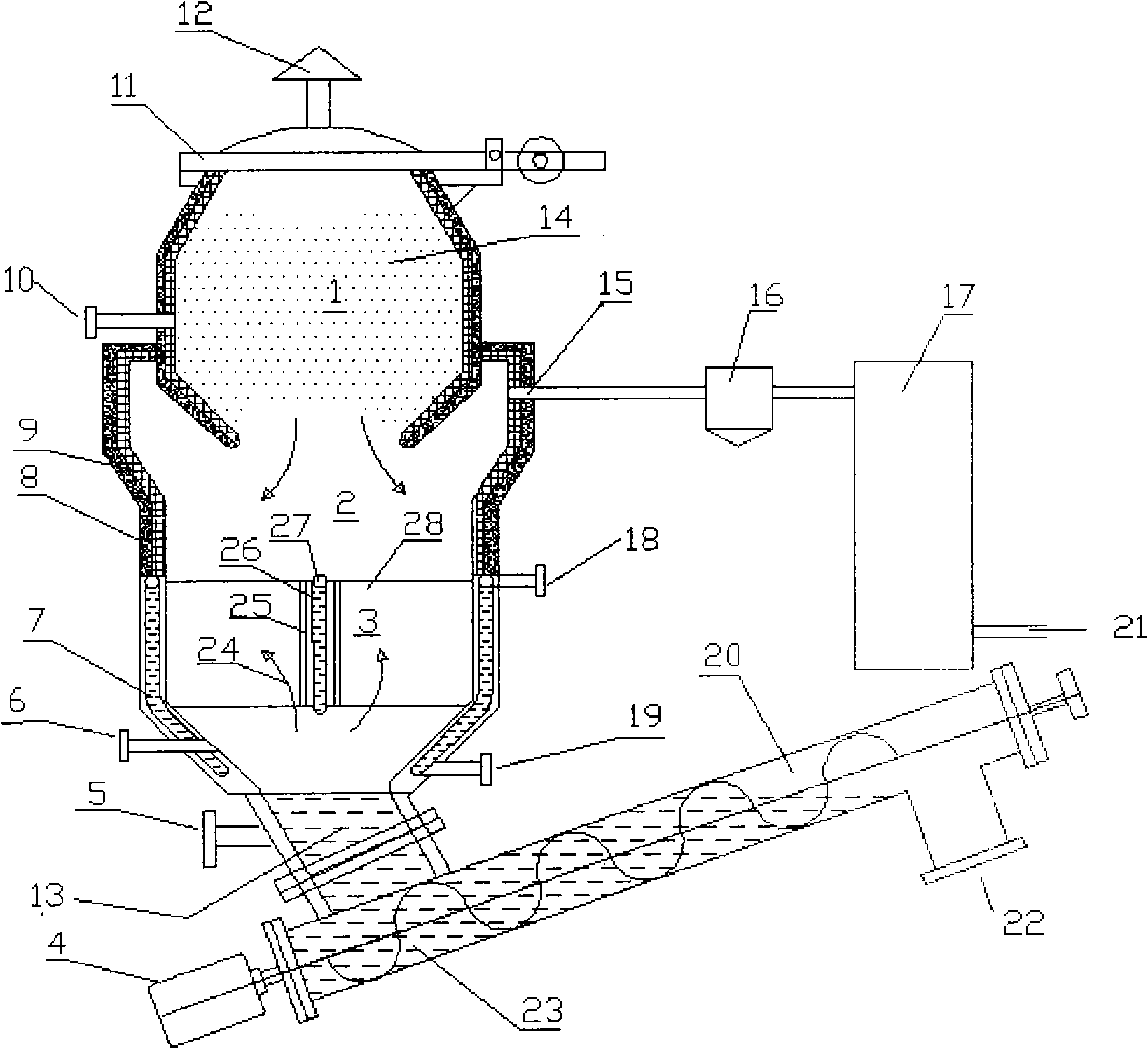

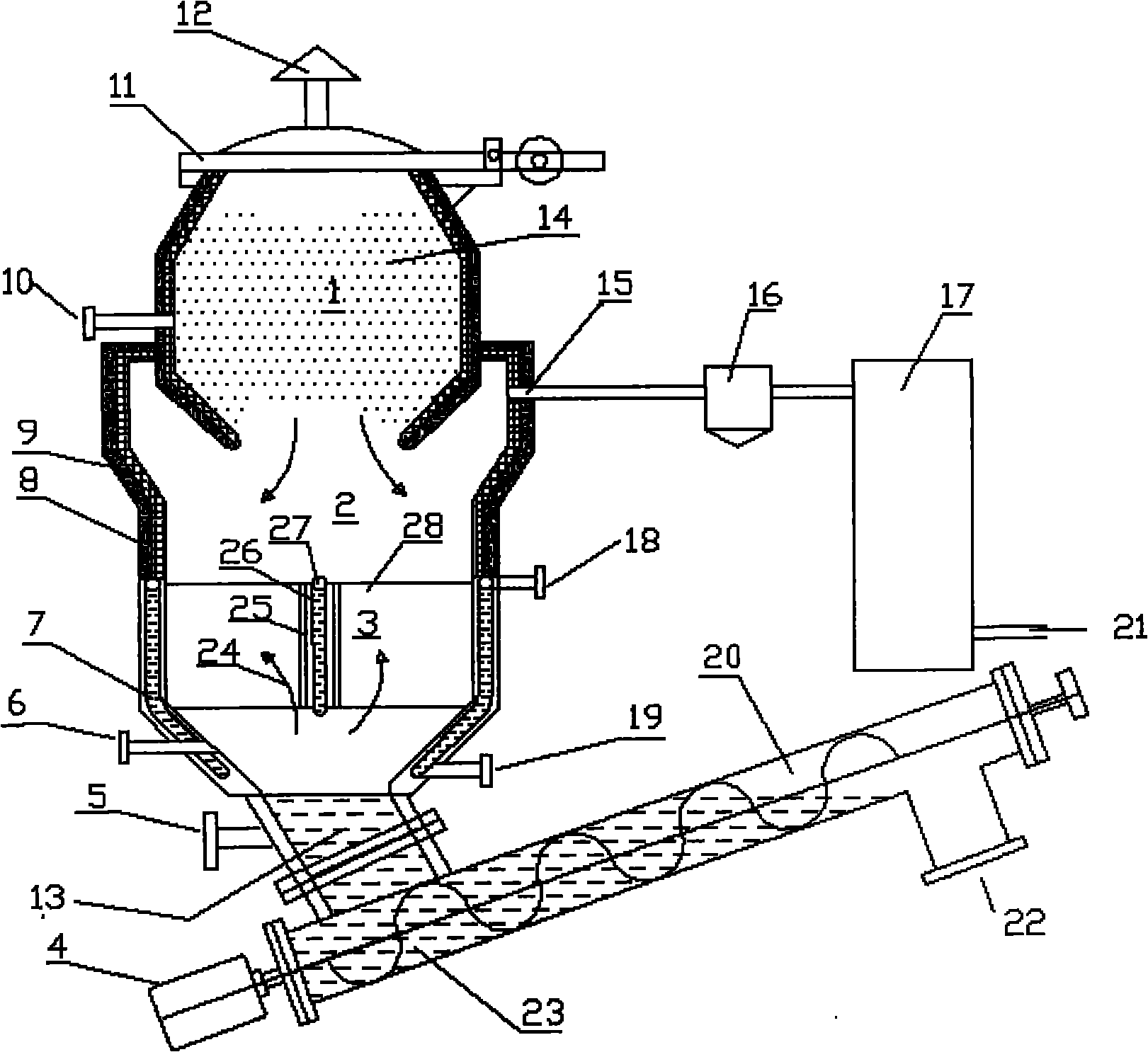

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

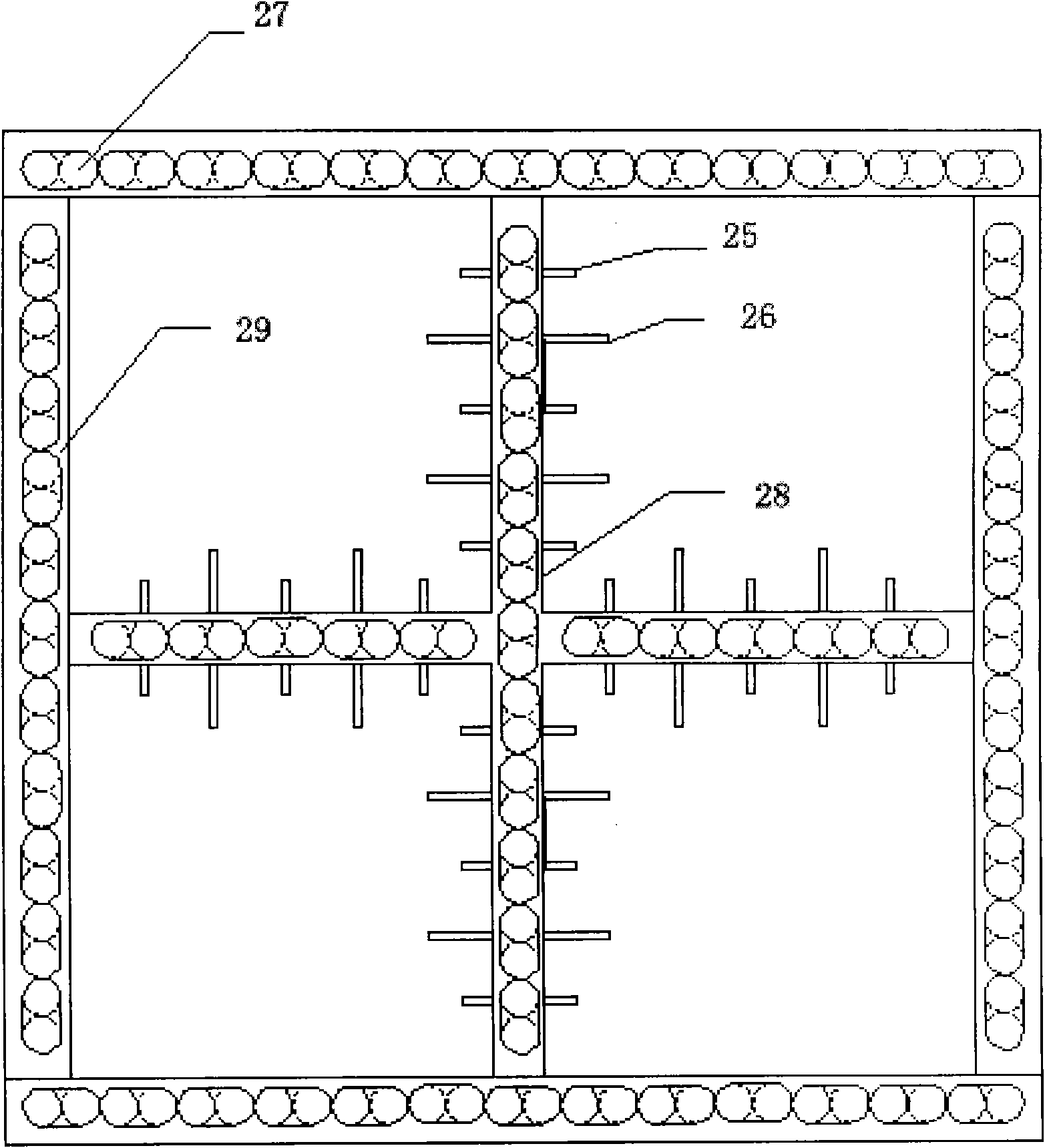

[0027] as attached figure 1 The shown CDQ energy-saving and emission-reducing device of the present invention includes fans connected by sequential air ducts, reduction coolers, dust collectors 16 and waste heat boilers 17, and fans (not shown) are placed before the reduction coolers, wherein, The reduction cooler is divided into a combustion chamber 1, a reduction section 2 and a cooling section 3 from top to bottom, wherein a furnace cover 11 is arranged on the top of the combustion chamber 1, and an air inlet 10 is opened on the furnace wall at the middle and lower part of the combustion chamber; There is a gas outlet 15 on the upper furnace wall, and the gas outlet communicates with the dust collector through the gas outlet pipe, and further communicates with the waste heat boiler 17; the CO2 inlet 6 is opened on the lower furnace wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com