Improved device and method for producing electrolytic manganese metal by two-ore method

A technology of electrolytic manganese metal and two-mine method, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of unresolved manganese sulfate solution purification and impurity removal technology, unstable process technology, and low yield of manganese metal , to achieve the effect of improving working conditions, mature production technology and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

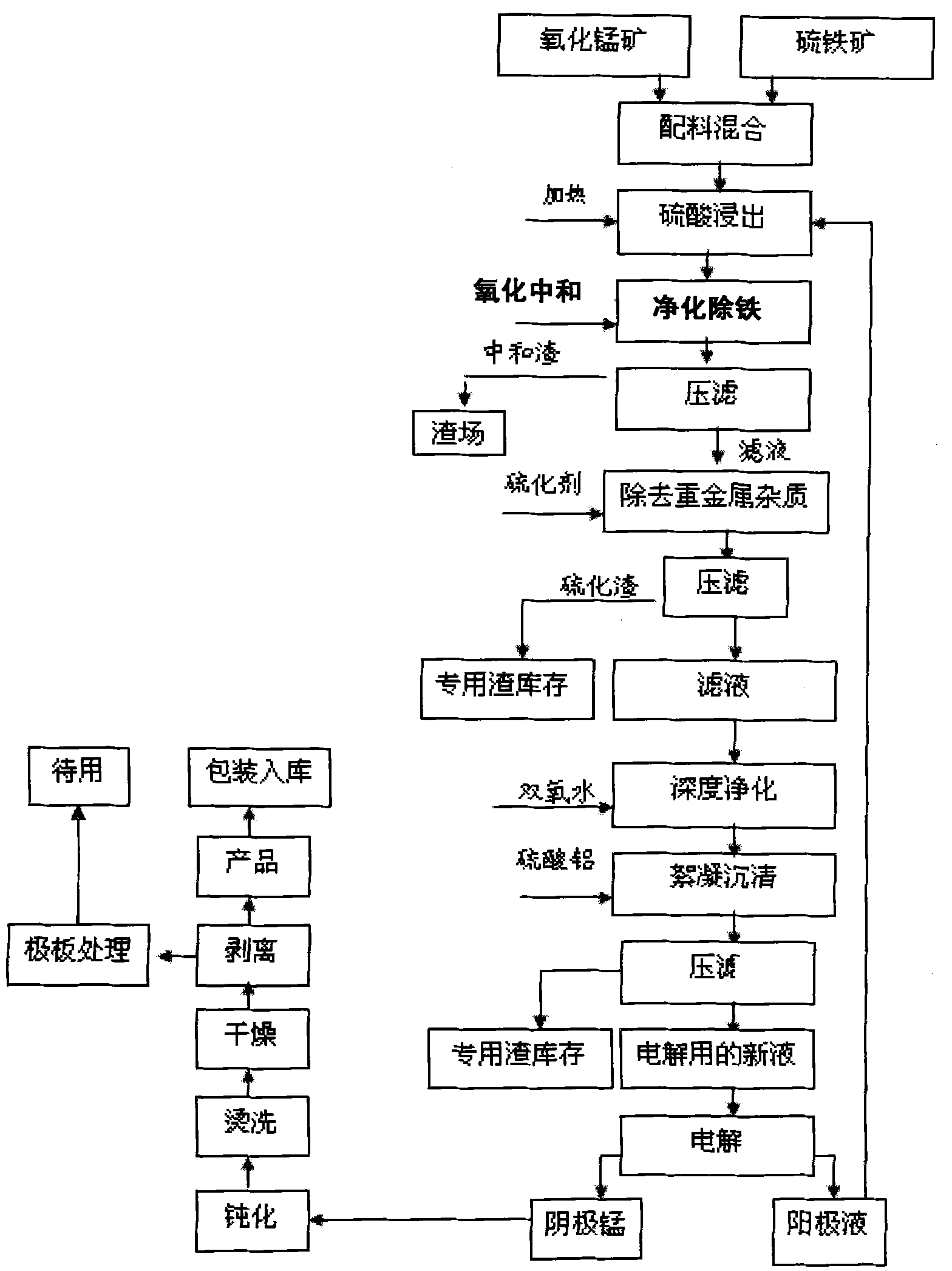

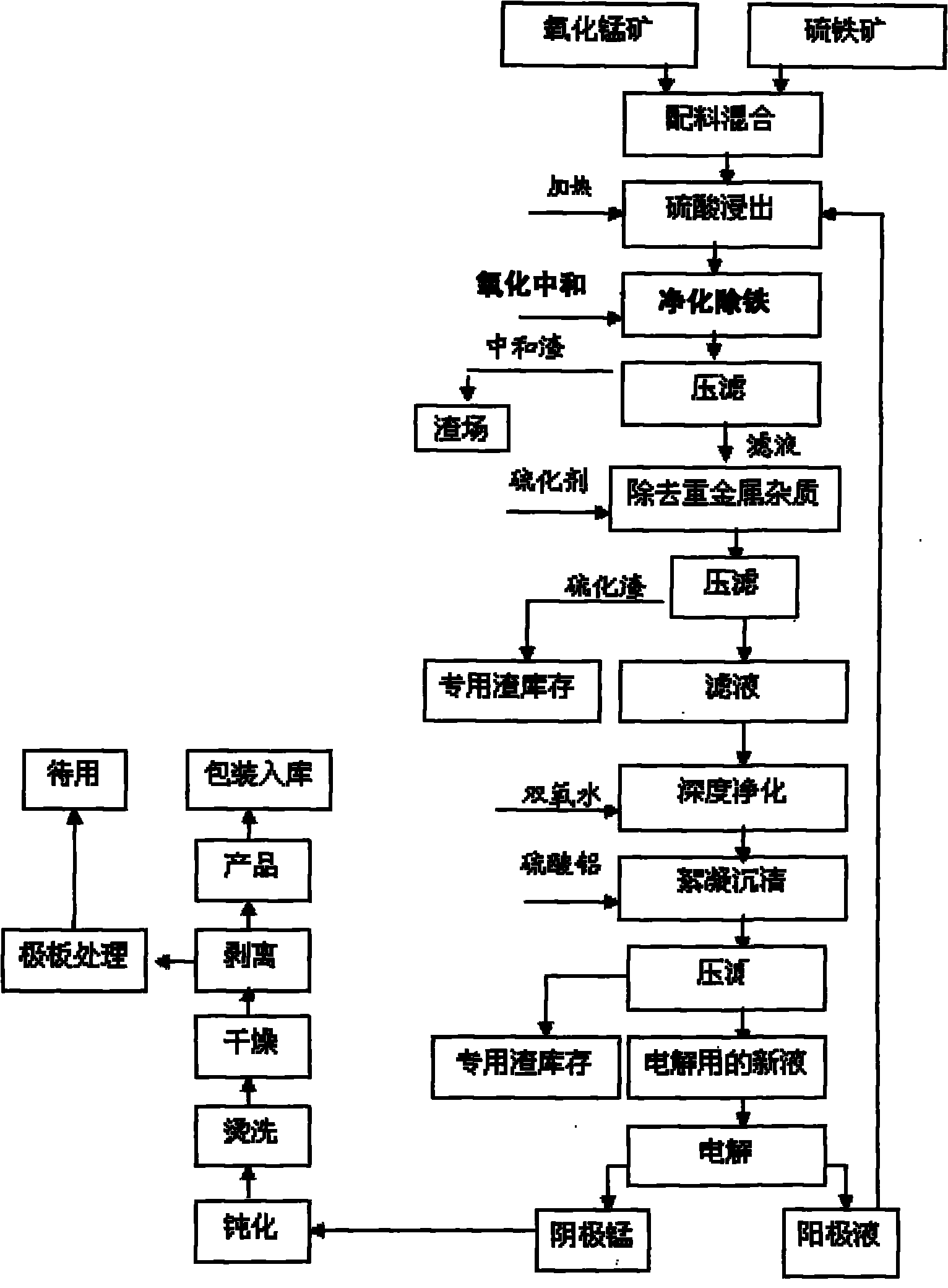

[0065] The method for producing electrolytic manganese metal by the two-mining method of the present invention is carried out according to the process steps of fine ore grinding, ingredient mixing, leaching, purification, deep purification, and electrolysis. The above-mentioned leaching step includes: using manganese oxide ore as a raw material, pyrite as a reducing agent, mixing two kinds of mineral powders (with a particle size of 100% of 80-130 mesh) with the anolyte according to the ratio, and directly leaching with heating and stirring in a sulfuric acid solution. MnSO 4 , Iron is Fe 2 (SO 4 ) 3 Into the solution. The invention improves the working conditions of workers and creates a way for the development and utilization of low-grade manganese oxide ore and non-ferrous metal ore dressing tailings (pyrite). After years of production tests, the present invention successfully solves the purification and impurity removal technology of manganese sulfate solution, obtains a qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com