Multifunctional composite fiber and preparation method thereof

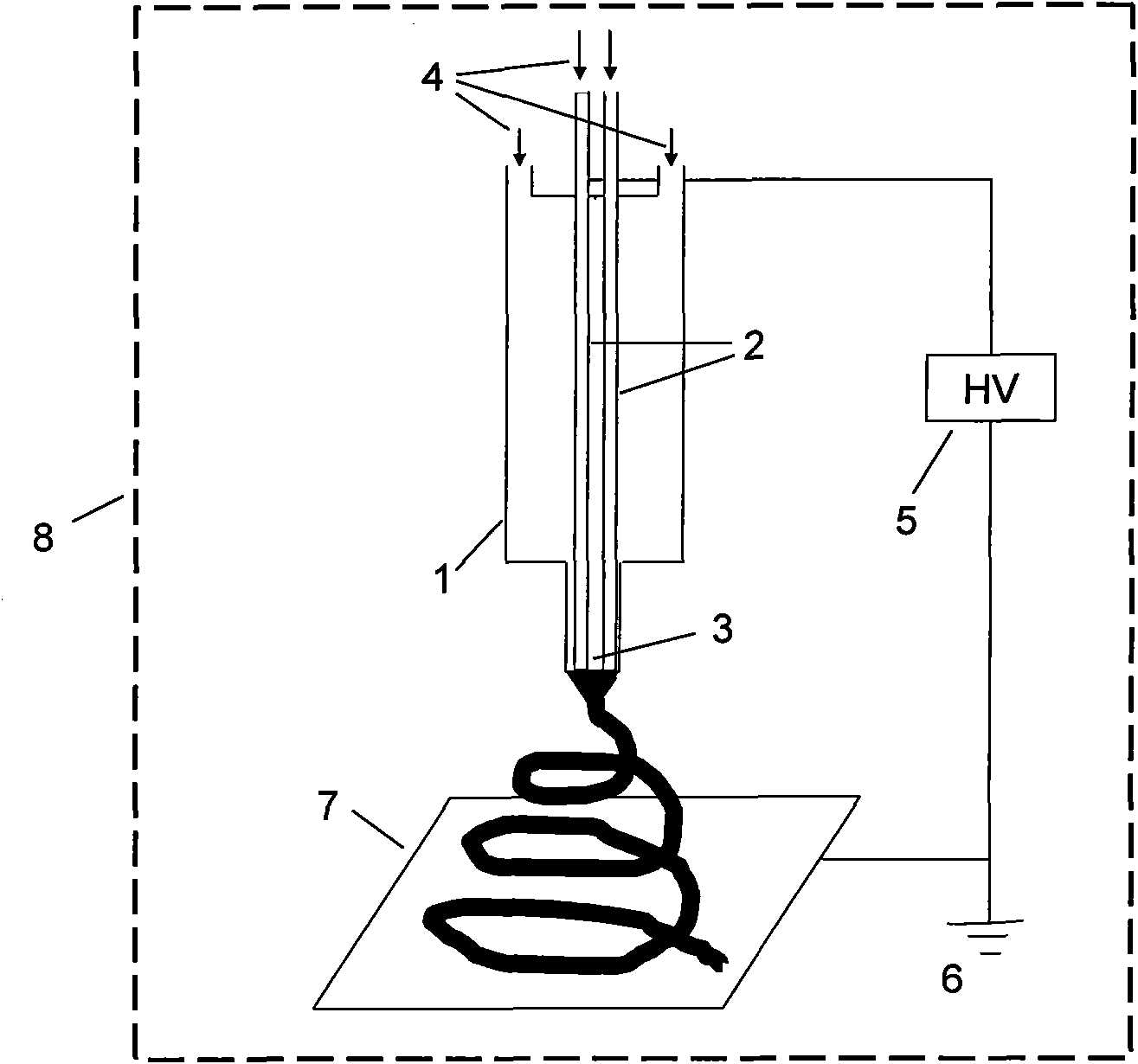

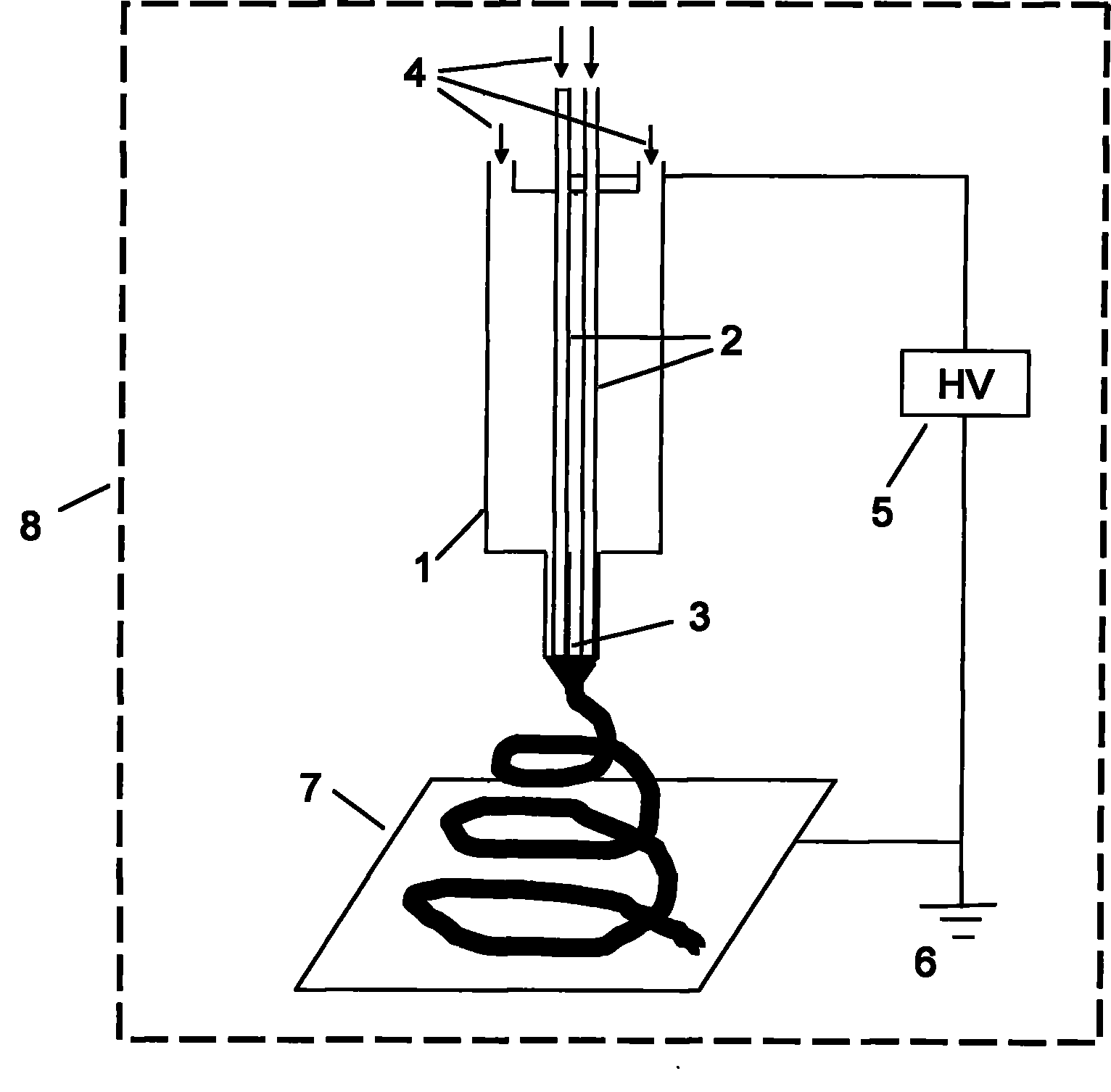

A composite fiber and multi-functional technology, applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of single phase change materials, etc., and achieve the effect of uniform dispersion, simple device, convenient and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

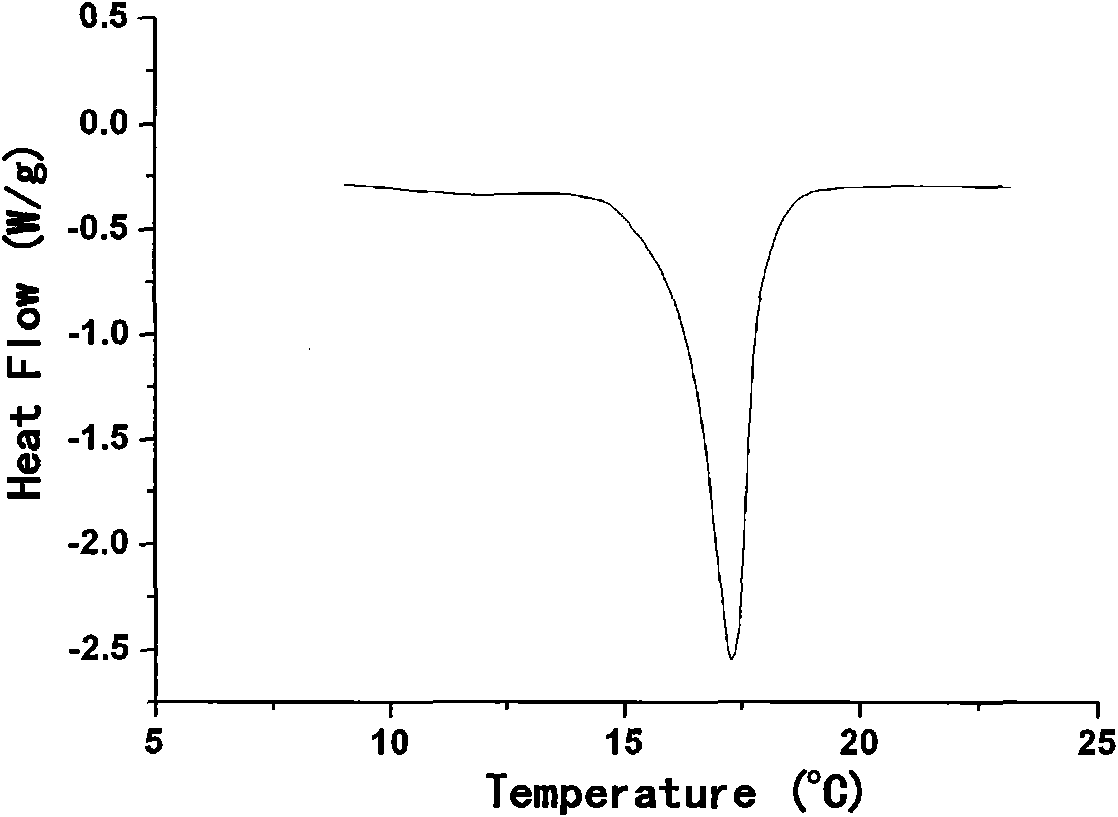

Embodiment 1

[0056] The first step: prepare the fiber core material solution, that is, the inner fluid.

[0057] (A) Prepare internal fluid A: select the hexadecane liquid in the phase change material directly as internal fluid A;

[0058] (B) Preparation of internal fluid B: respectively select crystal violet lactone as a chromogenic agent; The mass percentage of tetradecyl alcohol and tetradecyl alcohol is 1:2:50. Weigh 1.0 g of crystal violet lactone and 2.0 g of bisphenol A and dissolve them in 50 g of tetradecyl alcohol, and stir thoroughly to obtain internal fluid B.

[0059] The second step: preparing the solution of the fiber shell material, that is, the outer fluid.

[0060] Select polyvinylpyrrolidone in the polymer to prepare the fiber shell material, and select ethanol as the solvent for the fiber shell material: dissolve 10g of polyvinylpyrrolidone in 10g of ethanol and stir thoroughly to prepare a polyvinylpyrrolidone with a concentration of 50wt%. external fluid.

[0061]...

Embodiment 2

[0065] The first step: prepare the fiber core material solution, that is, the inner fluid.

[0066] (A) Prepare internal fluid A: select octanoic acid of fatty acids in the phase change material directly as internal fluid A, and its content is controlled by flow rate;

[0067] (B) Preparation of internal fluid B: choose rhodamine B lactam as a chromogenic agent; octyl p-hydroxybenzoate as a chromogenic agent; cetyl alcohol as a thermochromic material solvent to prepare internal fluid B, according to The mass percentages of B lactam, octyl p-hydroxybenzoate and cetyl alcohol are 1:50:100, respectively weigh 0.1g of rhodamine B-lactam and 5g of octyl p-hydroxybenzoate and dissolve them in 10g of cetyl alcohol ,, fully stirred, that is, the preparation of the inner fluid B. .

[0068] The second step: preparing the solution of the fiber shell material, that is, the outer fluid.

[0069] Select polymethyl methacrylate in the polymer to prepare the fiber shell material, choose N...

Embodiment 3

[0074] The first step: prepare the fiber core material solution, that is, the inner fluid.

[0075] (A) Prepare internal fluid A: select phase change material: tetradecane in paraffins is directly used as internal fluid A, and its content is controlled by flow rate;

[0076] (B) Preparation of internal fluid B: respectively select 1,2-benzo-6-diethylaminofluorane as a chromogenic agent; bisphenol A as a chromogenic agent and cetyl alcohol as a thermochromic material solvent to prepare an internal fluid B. According to the mass percentage of 1,2-benzo-6-diethylaminofluorane, bisphenol A and cetyl alcohol as 1:2:10, weigh 1g of 1,2-benzo-6-diethyl Dissolve aminofluorane and 2g of bisphenol A in 10g of cetyl alcohol and stir thoroughly to prepare internal fluid B.

[0077] The second step: preparing the solution of the fiber shell material, that is, the outer fluid.

[0078] Select polyacrylonitrile in polymer to prepare fiber shell material, choose N, N-dimethylformamide as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com