Preparation method of self-repairing transparent antibacterial coating

A technology of antibacterial coating and transparent coating, applied in the field of preparation of self-repairing transparent antibacterial coating, to achieve good antibacterial effect, high practical value, convenient and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: the preparation of transparent PAH / HA coating

[0043] Soak the treated quartz substrate in PAH (2mg / mL, pH=10) aqueous solution for 15 minutes, take out the substrate and wash with water, then soak in HA (2mg / mL, pH=3) aqueous solution for 15 minutes, take out the substrate and wash with water . Wherein, the pH values of the PAH and HA aqueous solutions are adjusted by using a 1 mol / L aqueous hydrochloric acid solution and a 1 mol / L sodium hydroxide aqueous solution.

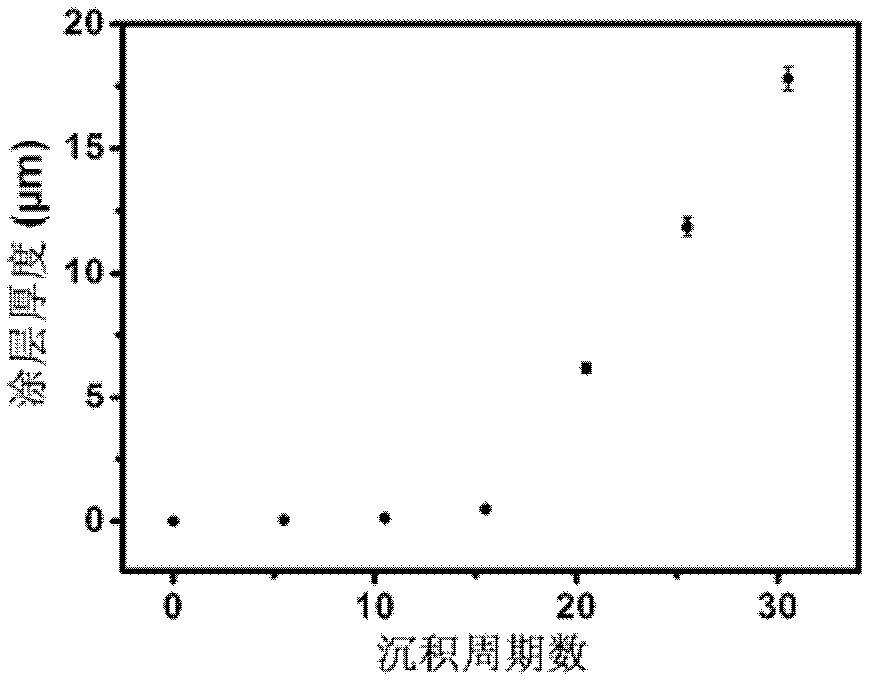

[0044] Repeat the above steps 30.5 times (that is, the last layer is the PAH layer) to obtain a transparent PAH / HA coating. figure 1 It is the relationship curve of the change of coating thickness with the number of deposition cycles tracked and monitored by scanning electron microscopy. It shows that the growth of the coating shows a typical exponential growth pattern, that is, the thickness of the coating increases rapidly as the number of deposition cycles increases. The thickness o...

Embodiment 2

[0045] Embodiment 2: the preparation of transparent antibacterial coating

[0046] (PAH / HA)*30.5 coating prepared as a protective coating on the surface of public display equipment must face various bacteria and viruses, so triclosan molecules with broad-spectrum antibacterial effects were selected as antibacterial agents and introduced (PAH / HA)*30.5 coating. Triclosan molecules are hydrophobic molecules, and it is difficult to directly introduce them into the hydrophilic (PAH / HA)*30.5 coating by ordinary methods, so the method of surfactant micelle coating is used to introduce hydrophobic triclosan molecules (PAH / HA) * 30.5 coating.

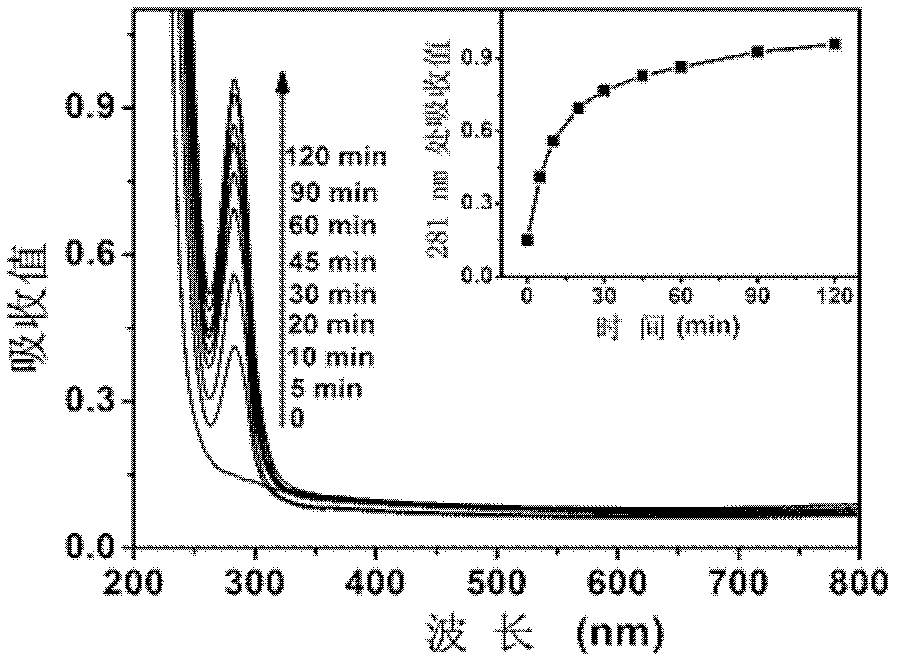

[0047] In this example, first add 0.2 mL of triclosan in dichloromethane (0.15 mol / L) dropwise to 40 mL of SDS in water (0.1 mol / L), and sonicate for 1 hour. Triclosan molecules will be encapsulated in the hydrophobic cavity of SDS micelles due to hydrophobic interactions. Then the (PAH / HA)*30.5 coating is immersed in the SDS micelles soluti...

Embodiment 3

[0048] Embodiment 3: the antibacterial ability of transparent antibacterial coating

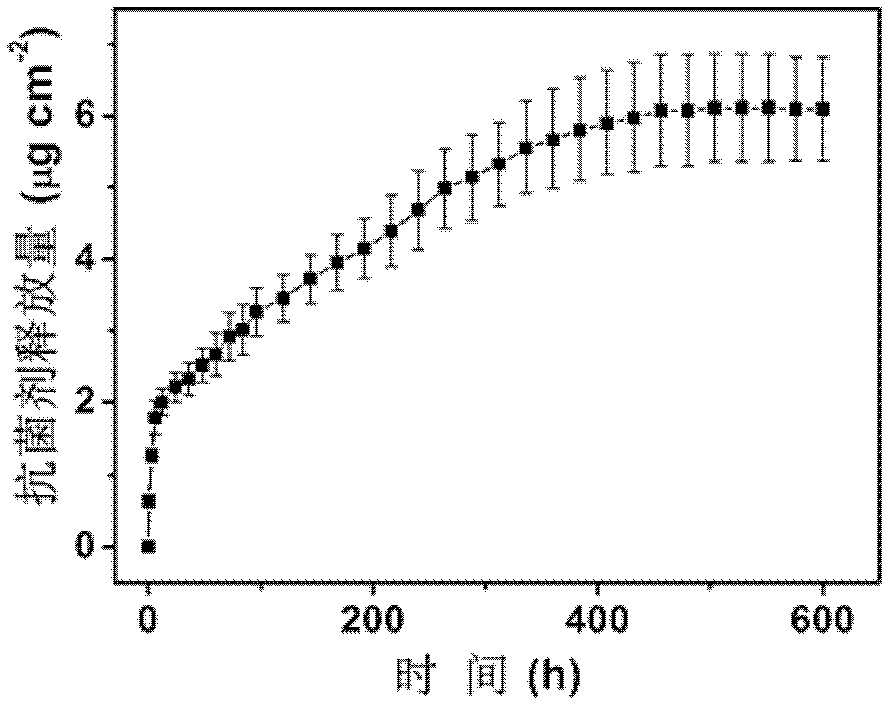

[0049] Sustained release of antimicrobial agents from the coating can effectively inhibit the growth of bacteria and maintain human health, so long-term release of antimicrobial agents is very necessary. The release profile of triclosan molecules loaded in (PAH / HA)*30.5 coating in water is shown as image 3 shown. Triclosan molecules will be continuously released in water. In the first 12 hours, the release rate of triclosan molecules is relatively fast, which is a typical release kinetics affected by diffusion. In the subsequent release, the release rate of triclosan molecules in water slowed down, and the entire release process could last for as long as 20 days. In the actual application of the transparent antibacterial coating, it is generally in an air environment with a certain relative humidity, so it can guarantee the antibacterial effect for a longer period of time, and can fully me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com