Vacuum-evaporation source, and organic EL element manufacturing apparatus

A technology for manufacturing a device and an evaporation source, which is applied in the field of evaporation sources, can solve the problems of difficulty in correctly controlling the temperature of evaporation materials, infiltration of organic materials, and poor temperature responsiveness, and achieves shortened startup time, effective utilization, and thermal responsiveness. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

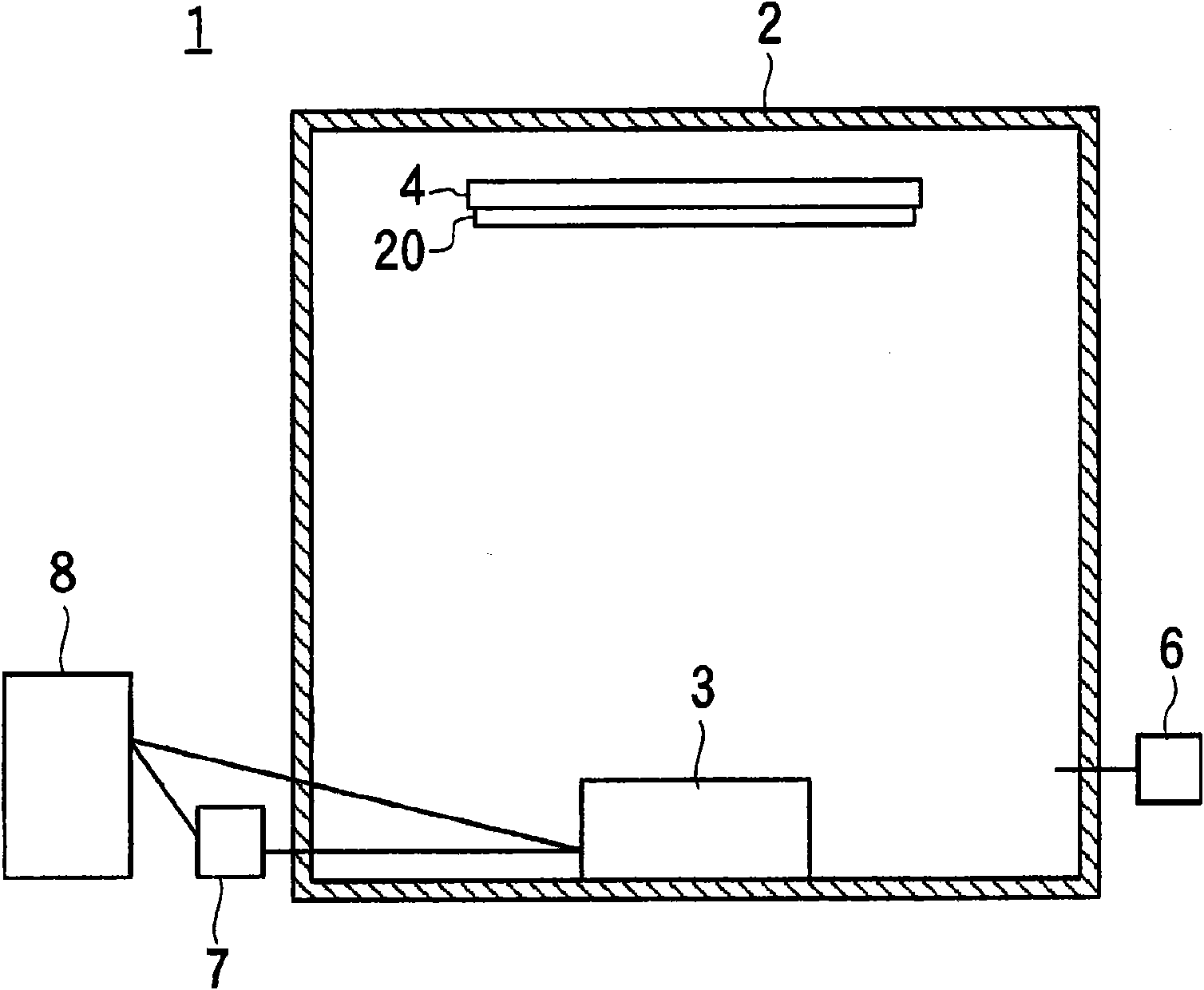

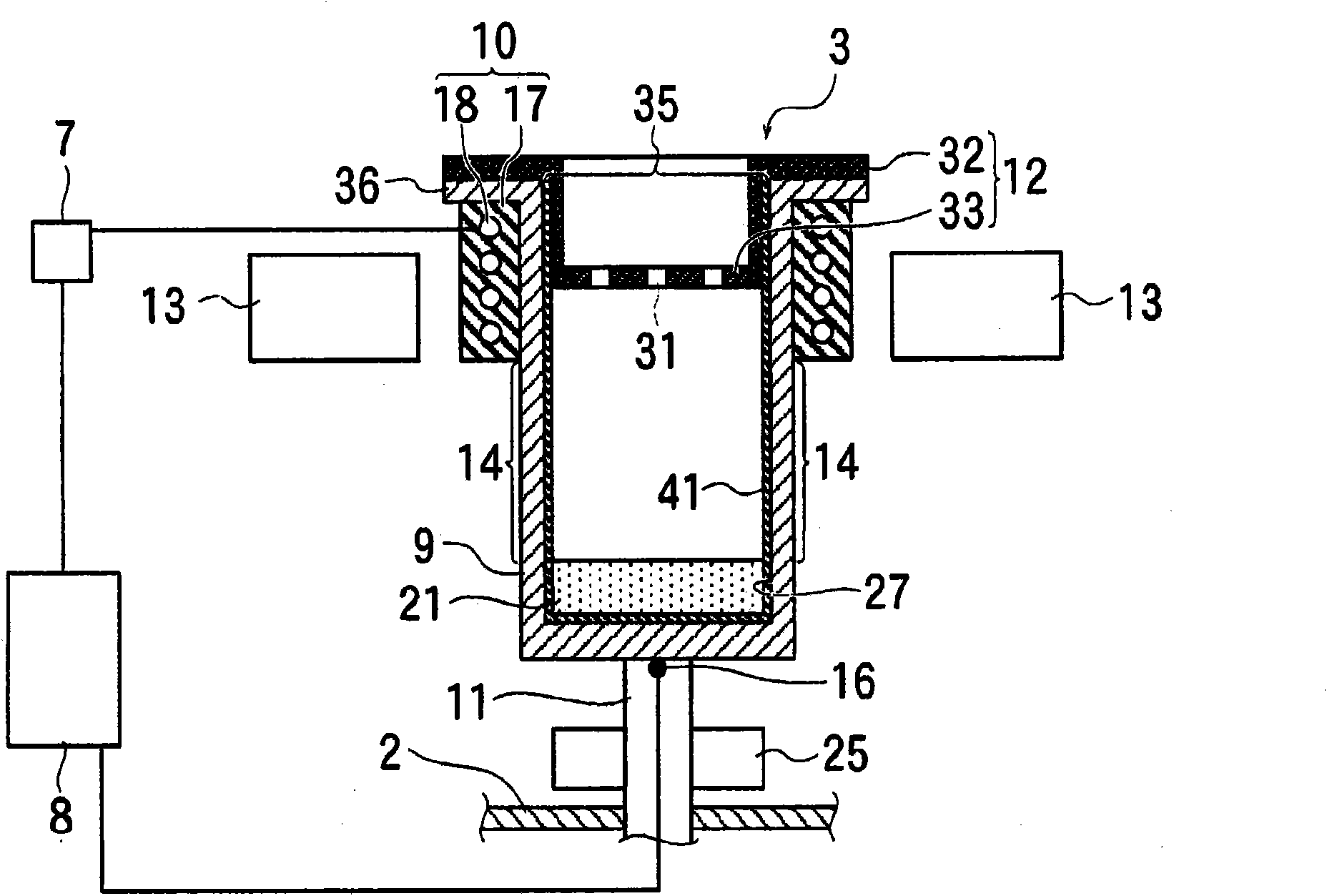

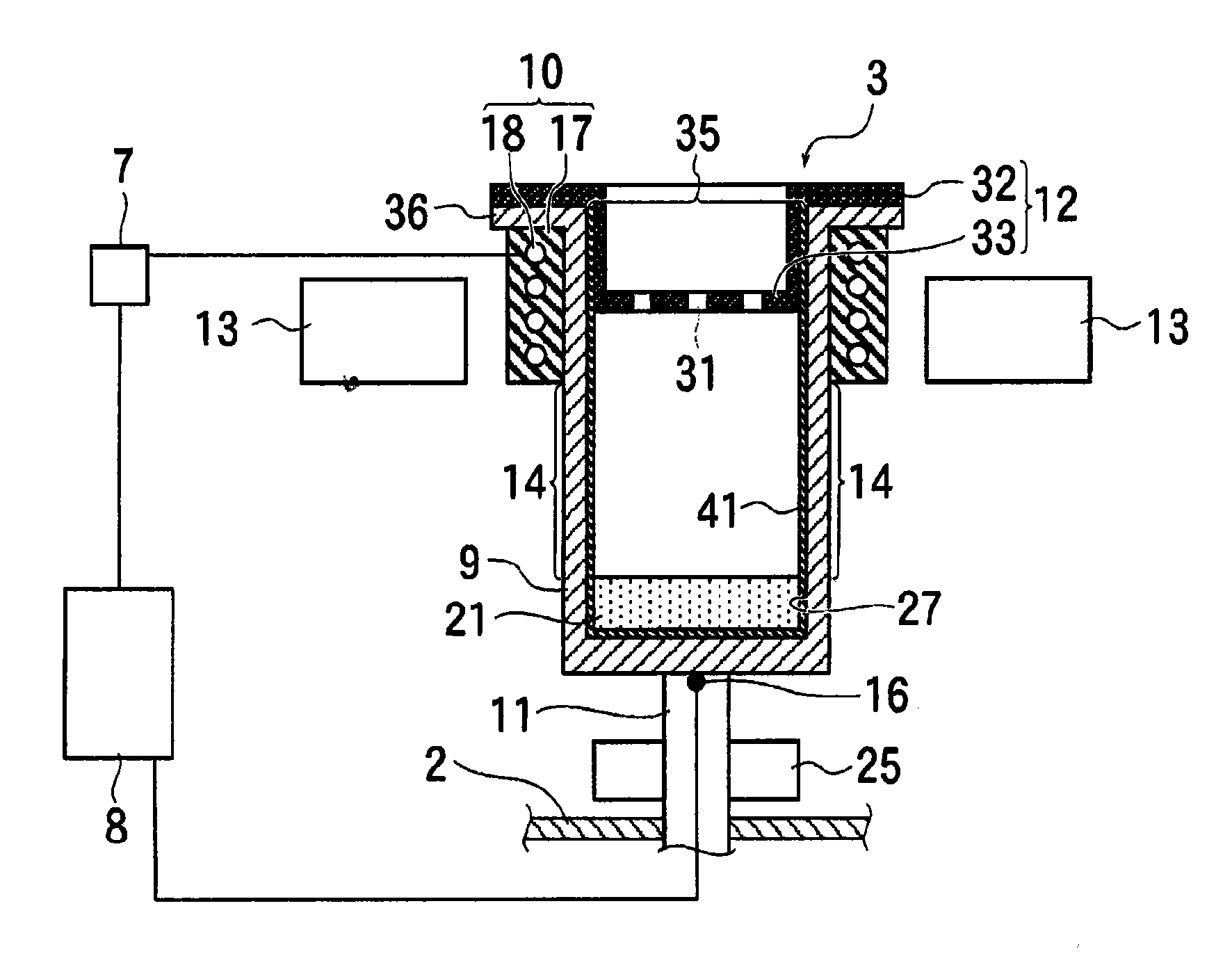

[0030] figure 1 The reference numeral 1 in the figure shows the manufacturing apparatus (vacuum evaporation apparatus) of the organic EL element which is an example of this invention. The vacuum evaporation device 1 has a vacuum tank 2 . A vapor deposition source 3 is arranged below the inside of the vacuum chamber 2 , and a substrate holder 4 is arranged above it. Evaporation source 3 such as figure 2 Shown are: evaporation vessel 9 , heating means 10 , and water cooling shroud 13 .

[0031] The heating device 10 has a ring shape and has a ring-shaped heat homogenizer 17 made of a material with high thermal conductivity. The heat spreader 17 is arranged in the vacuum chamber 2 so that its central axis is substantially vertical.

[0032] The evaporator 9 is vertically inserted into the ring of the heat homogenizer 17 with the opening 35 facing upward (the top side of the vacuum chamber 2 ).

[0033] Inside the heat spreader 17, a heating wire 18 wound concentrically with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com