Method for producing salinized dried bamboo shoots

A production method and a technology for dried bamboo shoots are applied in the production field of pre-salt treatment of dried bamboo shoots, which can solve the problems of perishable bamboo shoots, prolonged storage period, and easy deterioration of color and luster, so as to improve product quality, improve production efficiency and Product quality, the effect of prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

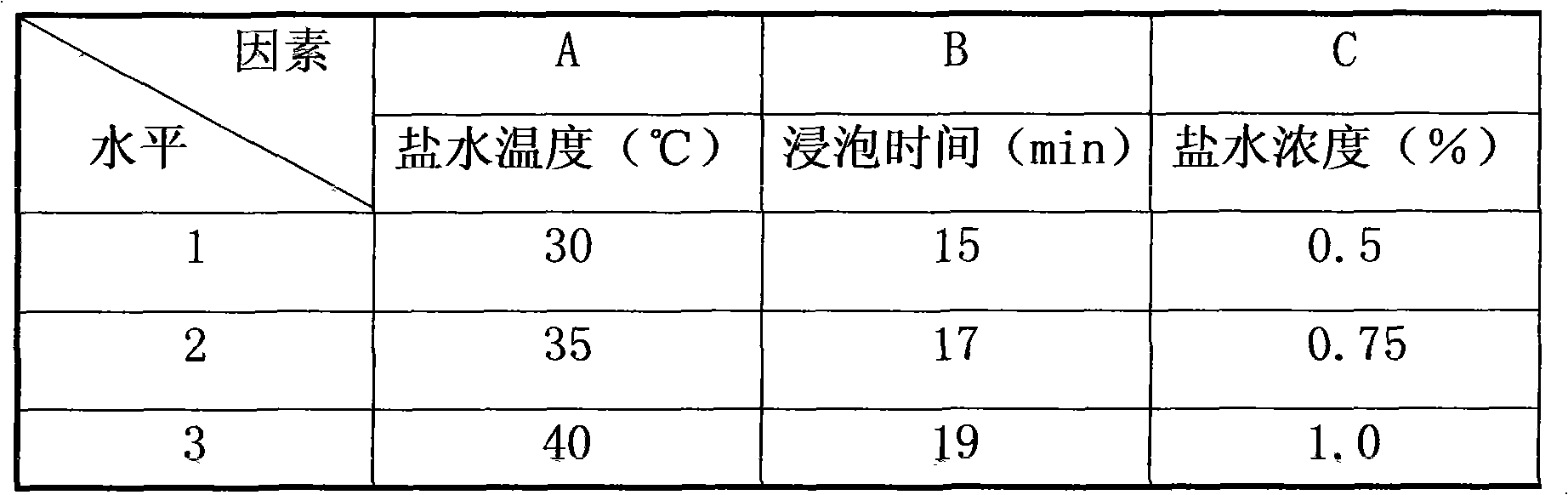

[0006] The production method of the present invention includes collecting fresh bamboo shoots, dehulling, removing old, trimming, cleaning, boiling and finishing, cooling and rinsing, pressing and fermentation, and drying; drying is natural drying or roasting, and is characterized in that: A salt water soaking step is inserted between the cooling and rinsing step and the pressing and fermentation step. The salt water soaking step is: the bamboo shoots treated by the previous step are soaked in salt water for 15 to 20 minutes, and the salt concentration in the salt water is 0.5 to 1% , The temperature is controlled at 30 to 42 degrees during soaking.

[0007] Experiments show that with the extension of the natural fermentation time, the number of yeasts in the bamboo shoots tends to increase. However, the total number of bacteria in the bamboo shoots increased sharply after 10 days when natural fermentation without salt was used, reaching 212 cfu / mL by 35 days, while natural ferme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com