High-temperature filter material with function of removing electrostatic coupling by using base fabric for electric-bag composite dust-collector and production method thereof

An electric bag compounding and electrostatic coupling technology, which is applied in chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of filter material holes, filter material strength reduction, filter material filtration failure, etc., to achieve the removal of electrostatic coupling, Prevents discharge damage and improves manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

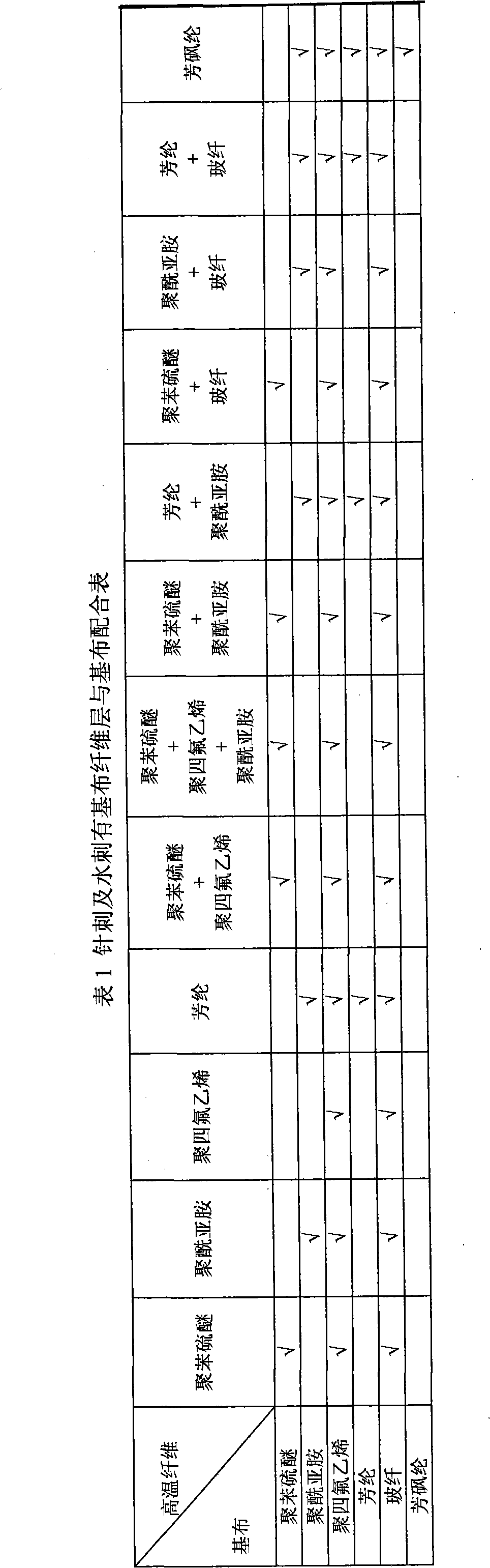

[0016] In this embodiment, the high-temperature fiber selects one kind of polyphenylene sulfide fiber;

[0017] Stainless steel fiber is selected as the high temperature resistant anti-static decoupling functional fiber;

[0018] The filter material is composed of two layers of fiber layers with base cloth sandwiched between them. The fiber layer is made of stainless steel fibers and polyphenylene sulfide fibers according to the proportion of stainless steel fibers accounting for 3% of the total fibers and polyphenylene sulfide fibers accounting for 97% of the total fibers Specific blending to form a uniformly blended fiber network with randomly arranged fibers, which is processed to form a porosity of 90% and a unit weight of 300g / m 2 The fiber layer; the base fabric is woven from polyphenylene sulfide yarn with a unit weight of 300g / m 2 of loose gauze.

[0019] The manufacture method of this filtering material all can obtain by following two kinds of methods:

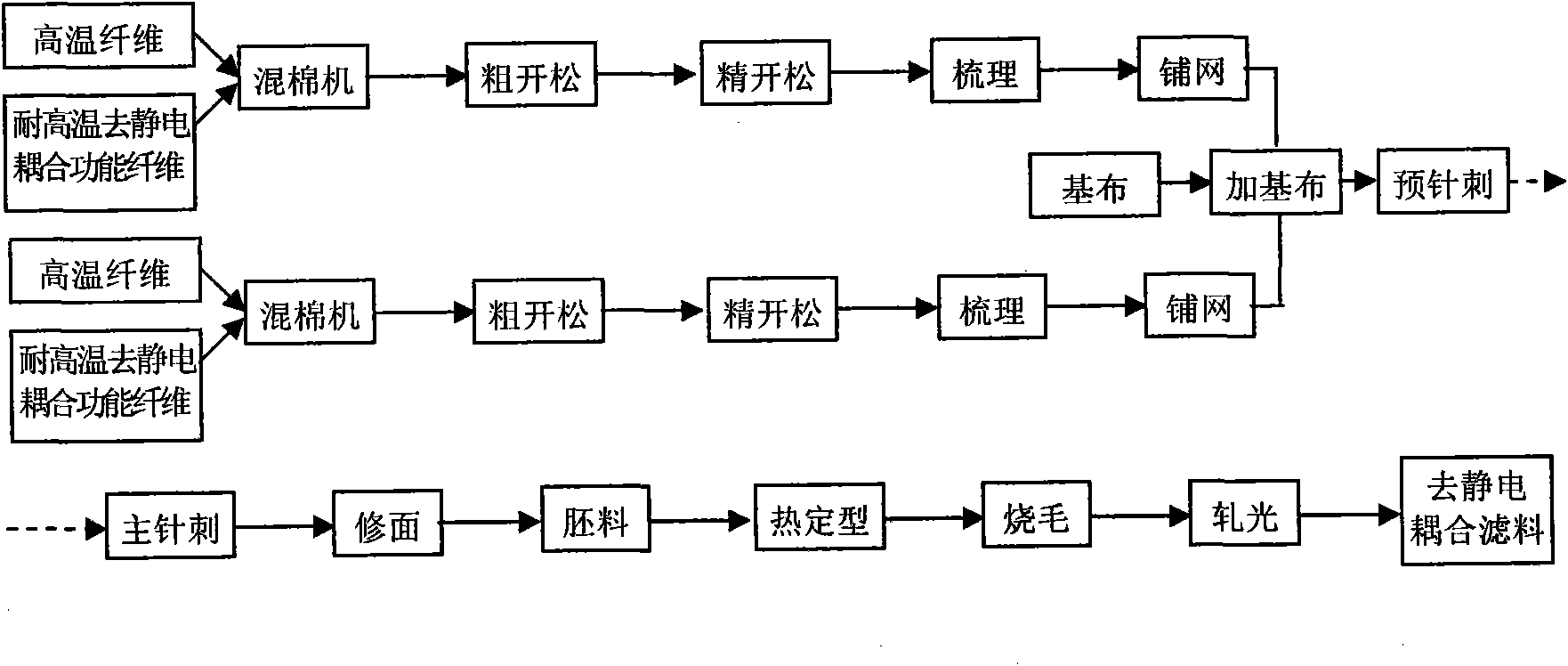

[0020] Acu...

Embodiment 2

[0023] The high-temperature fiber in this embodiment is obtained by combining aramid fiber, polyimide fiber, polytetrafluoroethylene and sulfonamide fiber;

[0024] Carbon fiber is selected as the high temperature resistant destatic coupling functional fiber;

[0025] The filter material is composed of two layers of fiber layers with a base cloth sandwiched between them. The fiber layer is composed of 10% carbon fiber and 90% aramid fiber, polyimide fiber, polytetrafluoroethylene and polysulfone fiber. The combination of high-temperature fibers is blended to form a uniformly blended fiber network with randomly arranged fibers, which is processed to form a porosity of 50% and a unit weight of 600g / m 2 The fiber layer; the base fabric is woven from polyphenylene sulfide yarn with a unit weight of 200g / m 2 of loose gauze.

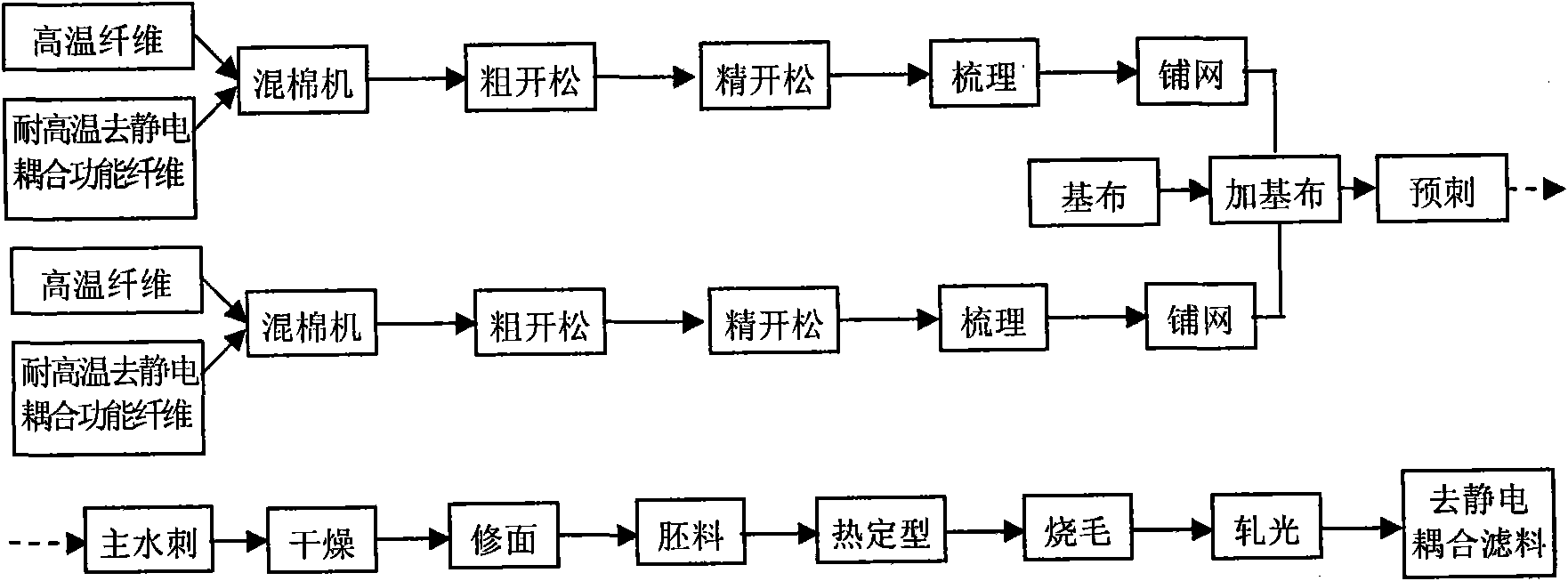

[0026] The manufacture method of this filtering material all can obtain by following two kinds of methods:

[0027] Acupuncture method: carbon fiber and hi...

Embodiment 3

[0030] In this embodiment, the high-temperature fiber is obtained by combining polyphenylene sulfide fiber and polyimide fiber;

[0031] Titanium fiber is selected as the high temperature resistant and electrostatic coupling functional fiber;

[0032] The filter material is composed of two layers of fiber layers with a base cloth sandwiched between them. It is a high-temperature fiber blended with a combination of titanium fibers accounting for 20% of the total fiber and polyphenylene sulfide fibers and polyimide fibers accounting for 80% of the total fiber. Mixed into a uniformly blended fiber network with randomly arranged fibers, processed to form a porosity of 10%, and a unit weight of 1000g / m 2 The fiber layer; the base fabric is woven from polyphenylene sulfide yarn with a unit weight of 50g / m 2 of loose gauze.

[0033] The manufacture method of this filtering material all can obtain by following two kinds of methods:

[0034] Acupuncture method: mix titanium fiber an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com